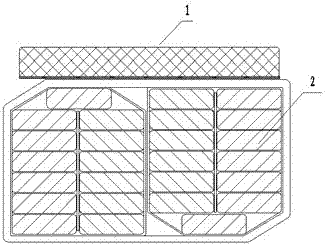

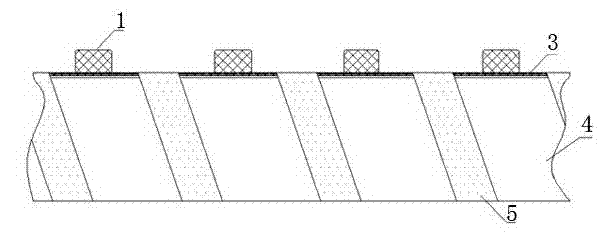

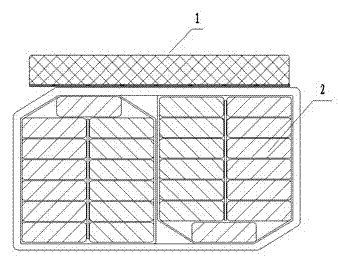

Combined transposition wire structure with prefabricated oil duct and manufacturing method thereof

A technology of transposition wire and production method, which is applied in the field of transformer manufacturing, can solve problems such as prone to tilt and dislocation, achieve the effects of reducing difficulty, avoiding easy tilt and confusion, and improving winding quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] 1) According to the technical requirements of the winding, determine the size and number of enamelled flat wires;

[0022] 2) According to the cross-sectional area requirements of parallel-wound conductors and the winding process requirements, determine the combined number and insulation thickness of the single-strand transposed conductors in the combined transposed conductors with (prefabricated) oil passages;

[0023] 3) Combined with the external dimensions of the combined transposition wire, customize the oil passage pad, and determine the arrangement interval, height, thickness, width and deviation of the oil passage pad;

[0024] 4) Make paper-wrapped transposed wires for combination, and combine single-strand transposed wires together and wrap insulating paper according to the number of combined wires;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com