Large power disc-type permanent motor stator

A permanent magnet motor, high-power technology, applied to the static parts of the magnetic circuit, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc. Maintenance costs and other issues, to achieve the effect of reducing volume and weight, good winding process, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

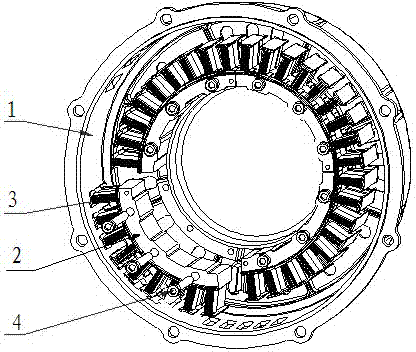

[0019] Example: See attached figure 1 , a high-power disc-type permanent magnet motor stator, including an annular iron core installed in an end cover 1, the annular iron core is composed of four single-piece iron cores 2, and the four single-piece iron cores 2 are detachable from each other The four single cores 2 are installed and fixed in the end cover 1 through the inner hexagon bolts 4, and each single core 2 is provided with a single stator winding 3 respectively. The single-piece iron core 2 and the single-piece stator winding 3 arranged on the single-piece iron core 2 constitute a single-piece stator.

[0020] During specific implementation, the annular iron core may be composed of two, six, eight or other number of individual iron cores 2 as required. The way of setting the single stator winding 3 on the single iron core 2 can be any way in the prior art.

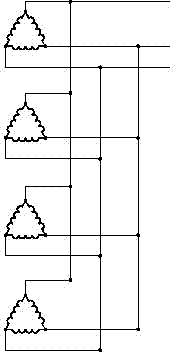

[0021] According to the requirements of the output power of the permanent magnet motor, there can be one or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com