Heating wire component in electronic cigarette and welding method of heating wire component

A welding method and heating wire technology, applied in the field of electronic cigarettes, can solve problems affecting the quality of heating elements, affecting product quality, and poor heating wires, and achieve the effects of pure smoke taste, ideal heating effect, and small resistance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Embodiment two: using a thermocouple welding machine as a laser spot welding machine, the implementation method steps are as follows:

[0037] 1. Adjust the machine: turn on the power switch, the thermocouple welding machine enters the standby state, press the "function key" on the control panel to enter the setting state, and the POWER state light starts to flash. Press the "+" and "-" buttons to adjust the energy required for welding the heating wire. According to the material and wire diameter of the heating wire, the energy needs to be adjusted. The general energy value ranges from 180 joules to 700 joules.

[0038] 2. Butt welding:

[0039] 2.1 Reliably connect the connecting clamp with the base metal;

[0040] 2.2 Turn on the power switch, the circuit starts to charge, the indicator light turns off, and the voltage reaches the set value when the indicator light turns red;

[0041] 2.3 Clamp the conductive wire 20 with welding pliers to realize electrical connect...

Embodiment 3

[0042] Embodiment 3: Using a precision resistance welding machine as a laser spot welding machine, the steps of the implementation method are as follows

[0043] 1. Precision resistance welding mechanical adjustment:

[0044] 1.1 Welding energy adjustment:

[0045] Press the "function key" on the control panel once in the standby state to enter the setting state, the POWER state starts to flash, press the "+ key" once to increase the welding energy by one, long press the "+ key" to increase the welding energy rapidly; press the "- key once "The welding energy is reduced by one, long press the "-" button to quickly reduce the welding energy. Press the "function key" four times to save the setting parameters and exit the setting state to enter the standby state. According to the material and wire diameter of the heating wire, the energy needs to be adjusted, and the general energy value ranges from 120 joules to 500 joules.

[0046] 1.2 Welding pulse adjustment:

[0047] Pre...

Embodiment 1

[0059] In Embodiment 1 and Embodiment 2, it is mainly operated manually, and auxiliary tools such as tweezers and scissors can be used. Use tweezers to twist and bind the stripped part of the conductive wire and the heating wire together, wrap the connecting end of the heating wire around the core wire of the connecting end of the conductive wire for 2-3 turns, and then cut off the excess stripped part to leave about 1.0mm.

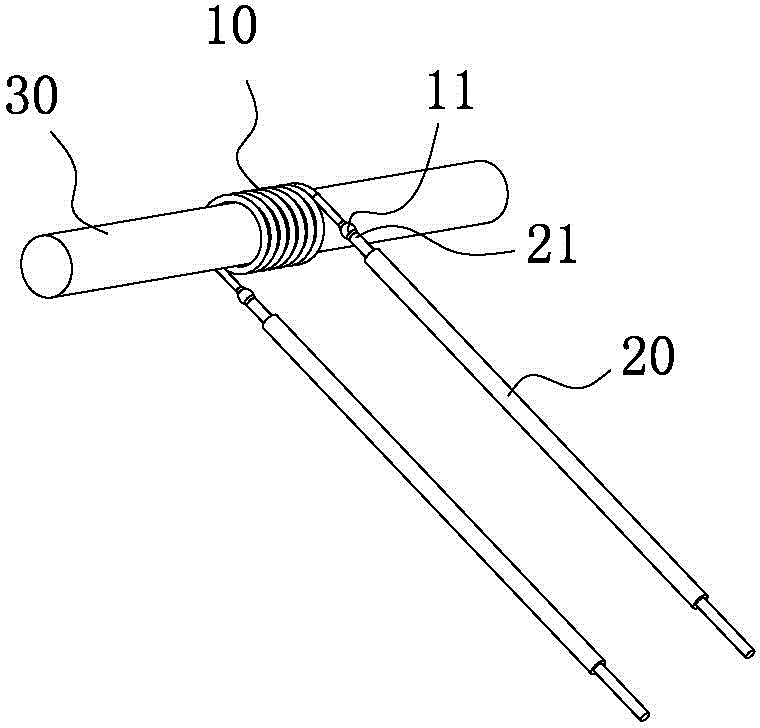

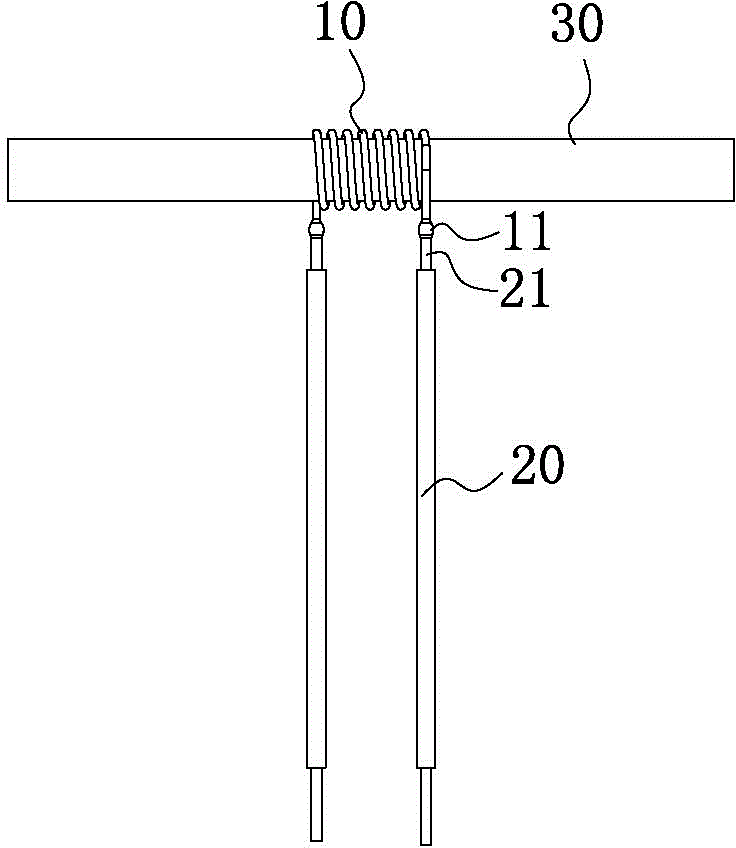

[0060] Among them, the third embodiment realizes mechanical automation operation, and these methods all use laser spot welding to directly weld the heating wire and the conductive wire without adding any other auxiliary solder. The two ends of the heating wire 20 wound on the oil-absorbing rope 30 and the two conductive wires can be welded to complete the heating wire assembly according to the above process in sequence. After adopting the above scheme for welding, the present invention has the advantages of small and firm welding points after welding, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com