Common part afflux assembly of refrigerating device

An assembly and refrigeration equipment technology, applied in the field of air conditioning and refrigeration equipment, can solve the problems of heavy workload, easy failure, and complicated installation during replacement and maintenance, and achieve the effect of reducing inspection time, reducing solder joints, and simplifying maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing this patent is further described.

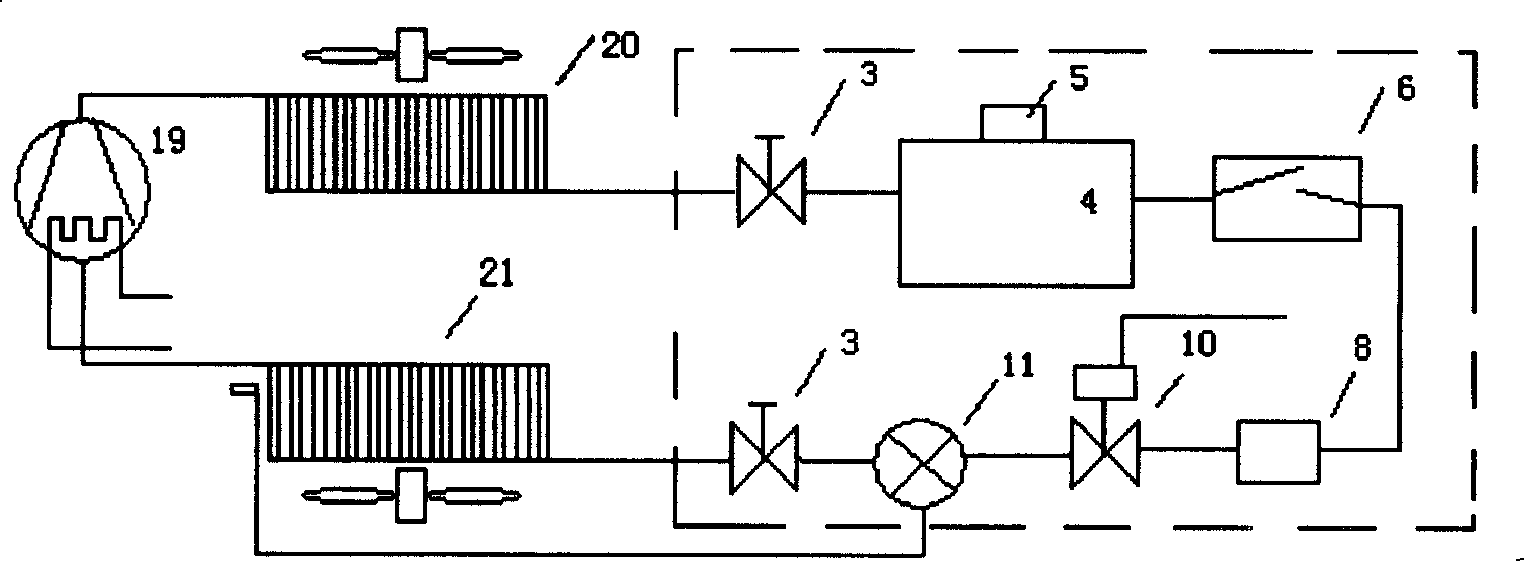

[0011] Such as image 3 As shown, the general refrigeration system consists of compressor 19, condenser 20, stop valve 3, liquid storage tank 4, safety valve 5, filter 6, sight glass 8, solenoid valve 10, expansion valve 11, evaporator 21 and other components form a refrigeration circuit. Due to the large number of components in the dotted box, they are easily subject to various restrictions during factory assembly. At the same time, when a component fails, it is necessary to check each component to confirm whether it is normal, and the maintenance work is very cumbersome.

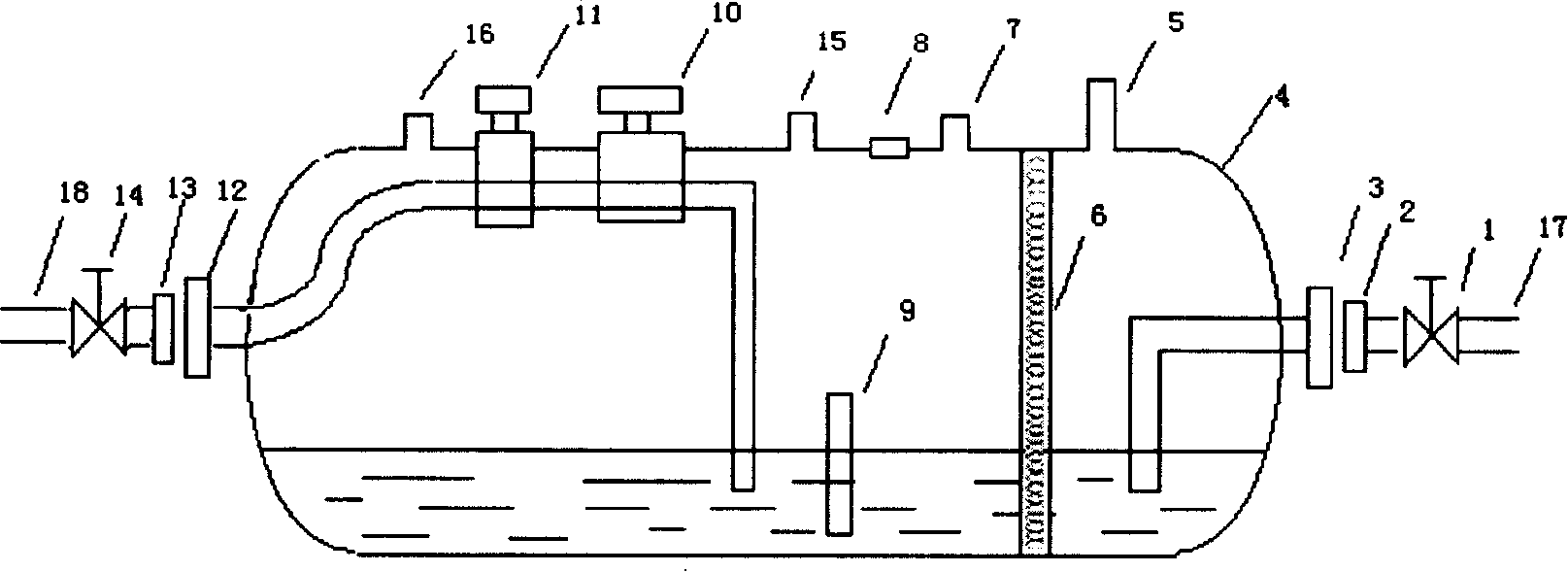

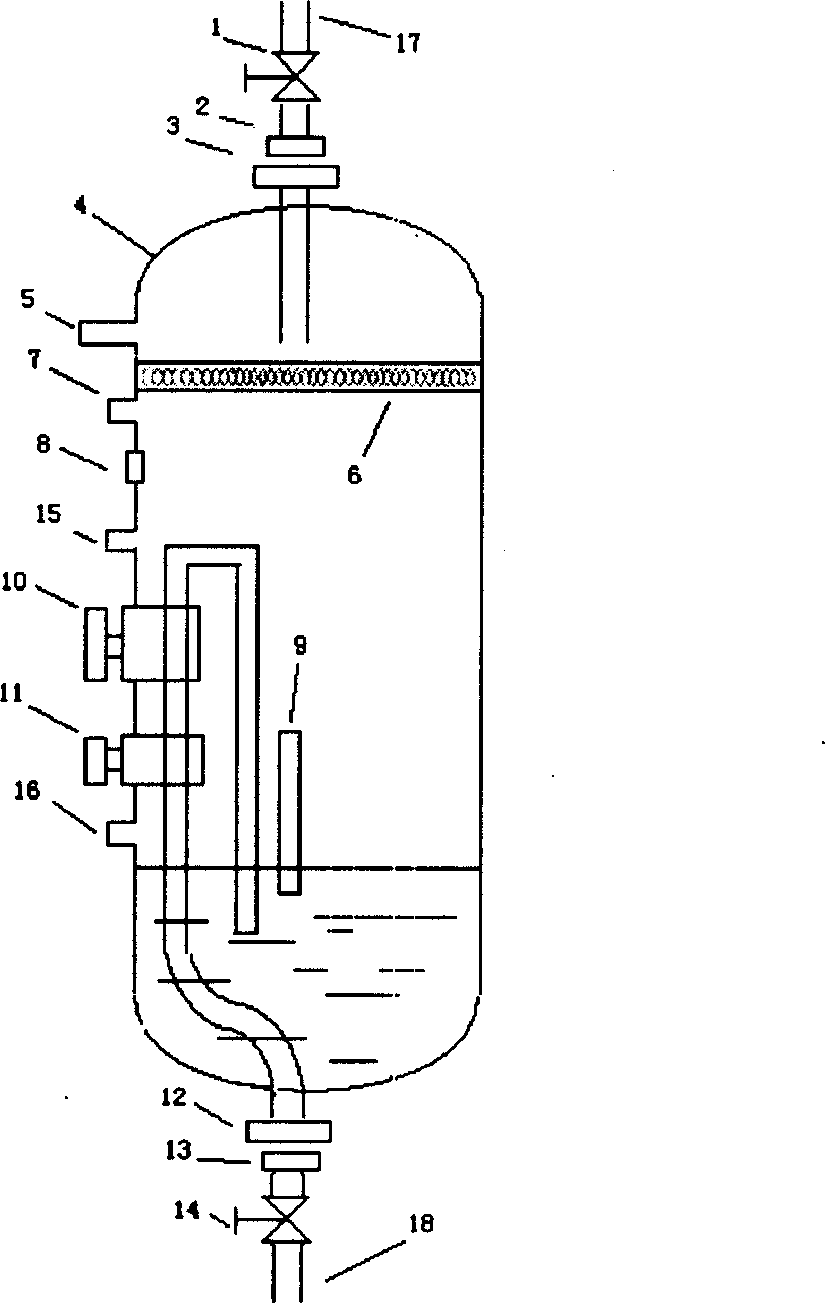

[0012] The present invention will image 3 The components in the dotted box are assembled into an assembly, such as figure 1 shown.

[0013] 2, 3 and 12, 13 are distributed at the two ends of the assembly as screw ports and screw heads, which facilitate the disassembly of the assembly. Multifunctional interfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com