Solar battery for solar mobile phone battery and preparation method thereof

A technology for solar cells and mobile phone batteries, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of increasing preparation workload, affecting light incidence rate, generating bubbles, etc., to avoid poor control of size and high photoelectric conversion efficiency , Increase the effect of bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

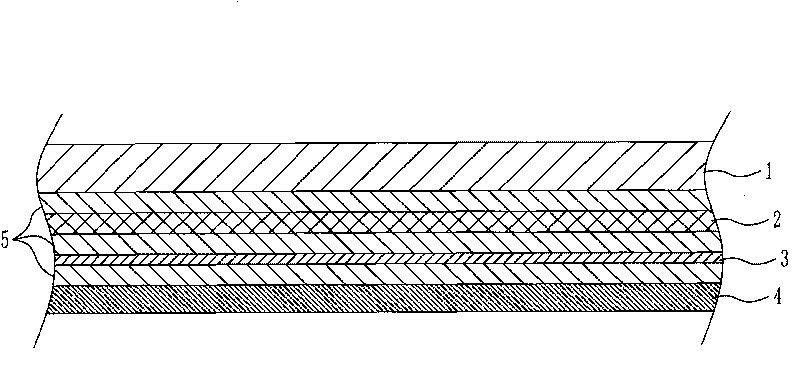

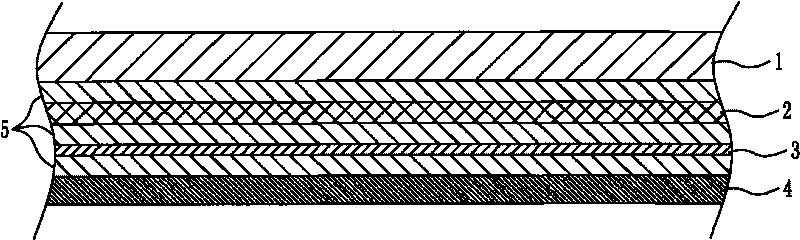

[0032] See attached figure 1 Shown, a kind of preparation method of the solar cell that is used for solar mobile phone cell assembly comprises the steps:

[0033] (1) After the epoxy resin board is cleaned, the adhesive, glass fiber surface mat and crystalline silicon battery are sequentially stacked on it;

[0034] (2) Weld the lead-out electrode of the crystalline silicon cell with the solder spot on the bottom surface of the epoxy resin plate, and then paste polyvinyl fluoride tape on the crystalline silicon cell relative to the position of the lead-out electrode;

[0035] (3) Laminate adhesive and tempered glass on crystalline silicon cells;

[0036] (4) Laminating the stacked battery components above at a temperature of 140-150° C., a pressure of 0.5-0.6 atmospheres, and a time of 10-20 minutes;

[0037] (5) Cooling and shaping, that is, obtaining the solar cell used for the solar mobile phone cell assembly.

[0038] In the above technical solution, the crystalline sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com