Liquid receiver

A liquid reservoir and cylinder technology, applied in the field of liquid reservoirs, can solve the problems of high welding cost and raw material cost, unstable welding quality of the liquid reservoir, and increased cost of the manufacturer, so as to achieve improved welding efficiency, simple structure, The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

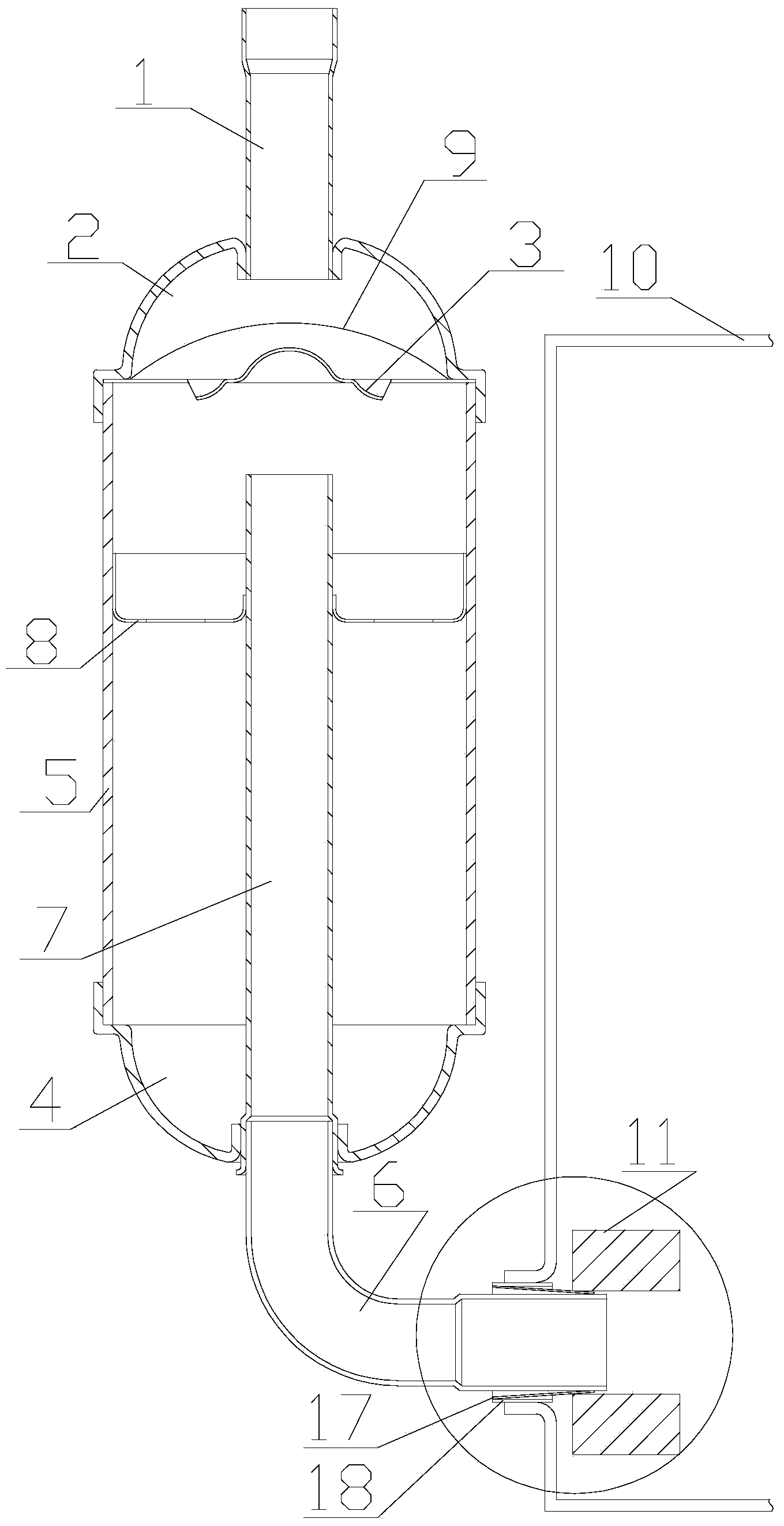

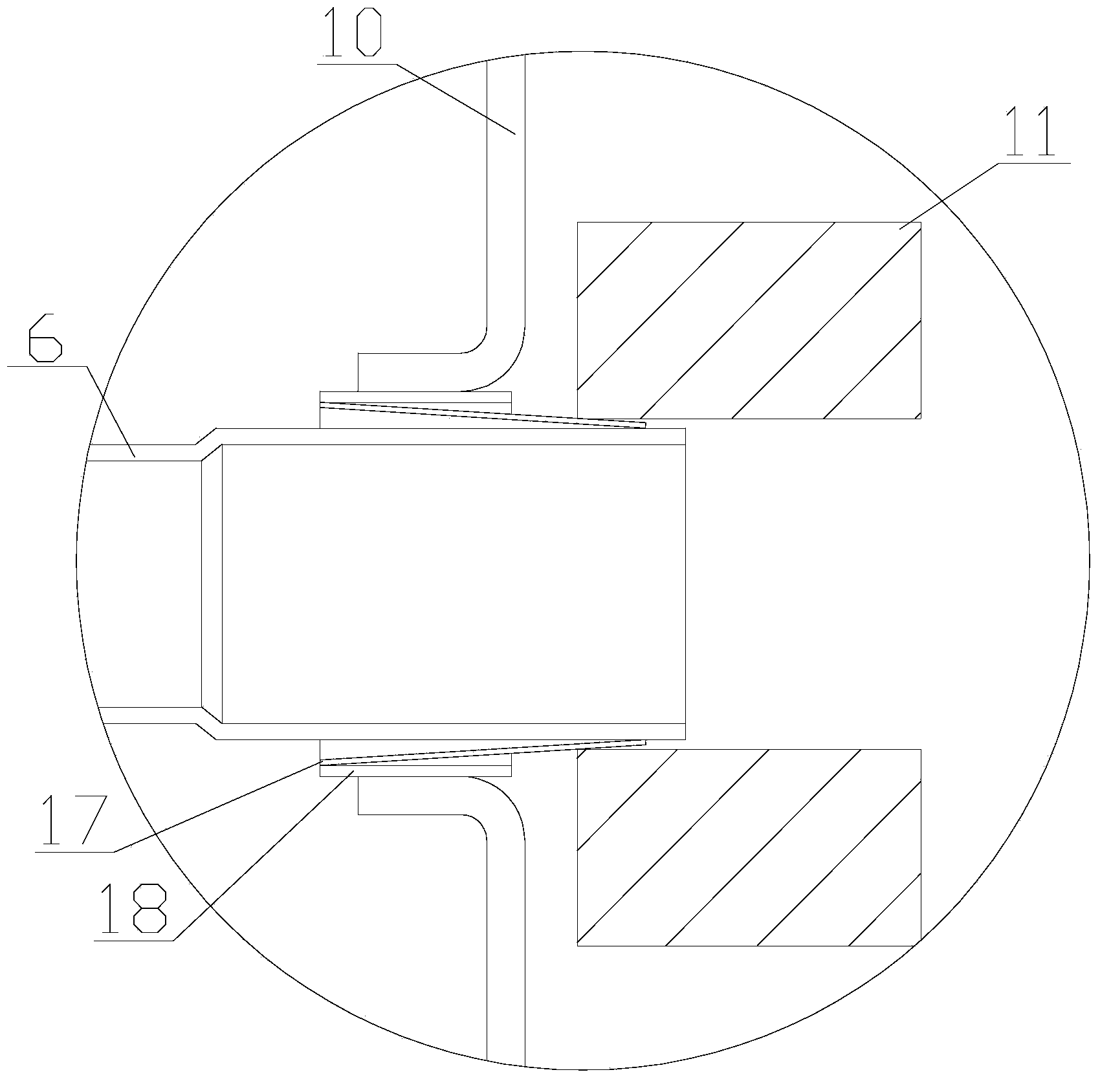

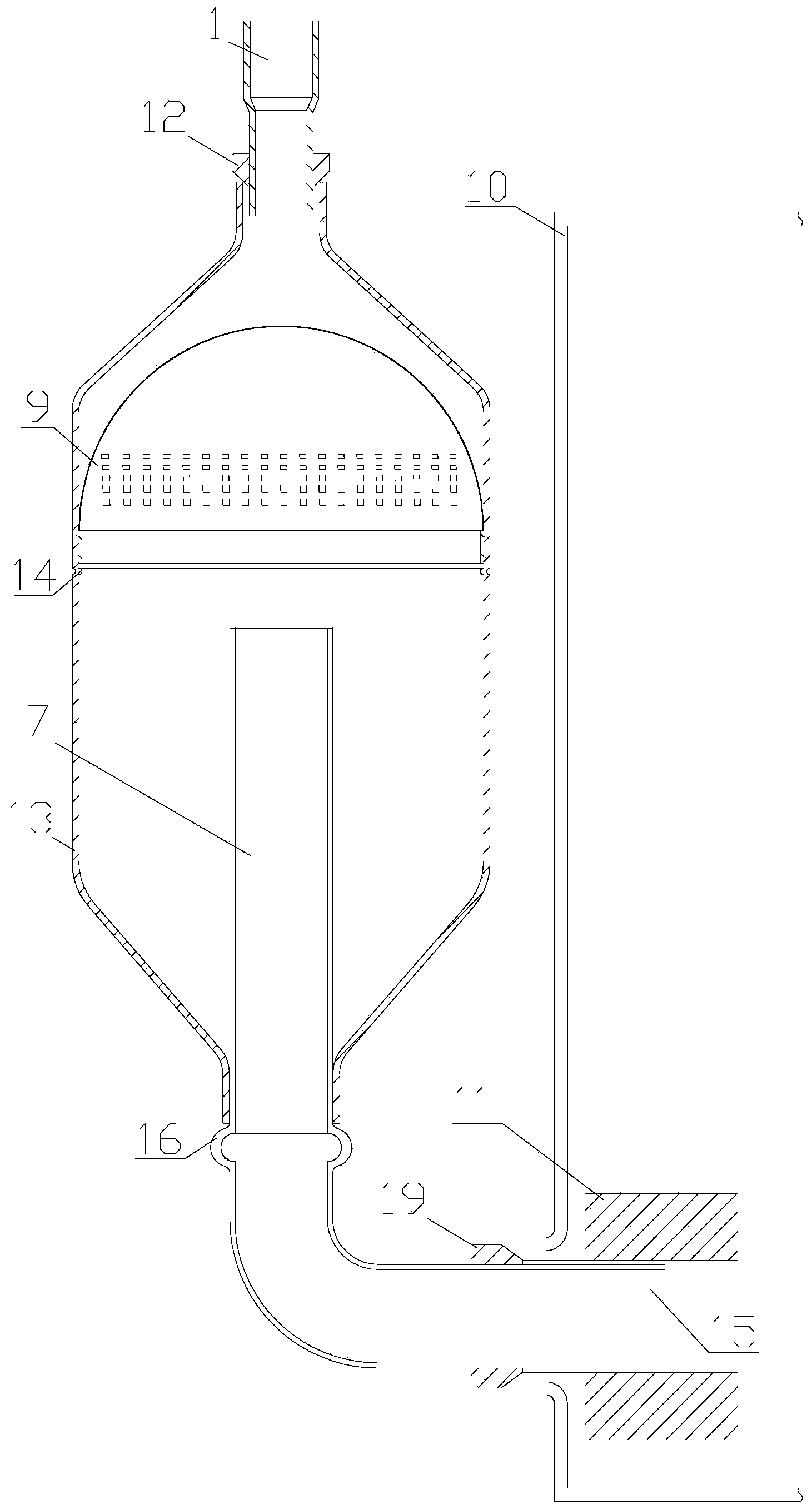

[0016] Embodiment: a kind of accumulator, is connected on the compressor, as image 3 As shown, the liquid reservoir includes a cylinder, the front end of the cylinder is provided with an air intake pipe, and the first flange is provided on the air intake pipe; the rear end of the cylinder is provided with an iron pipe, and the tail end of the iron pipe is provided with a centerless mill. Iron pipe, the connection between the iron pipe and the centerless grinding iron pipe is sleeved with a second flange, and the second flange is connected to the shell of the compressor; the centerless grinding iron pipe is connected to the compressor through interference fit The cylinder bore is connected; the flange, cylinder body and iron pipe are made of iron material, and the intake pipe is made of copper material; the cylinder body is also provided with a filter screen and positioning bumps, and the positioning bumps are rolled The process fixes the filter screen on the cylinder; the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com