One-dimensional nanomaterial welding method based on electrically-induced heating effect

A technology of nanomaterials and welding methods, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

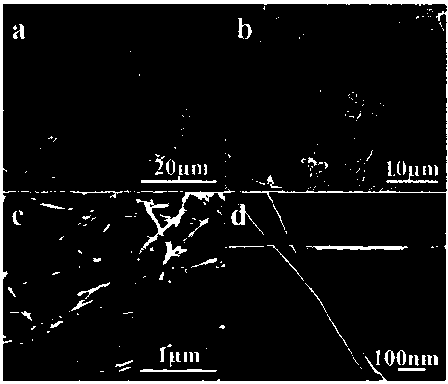

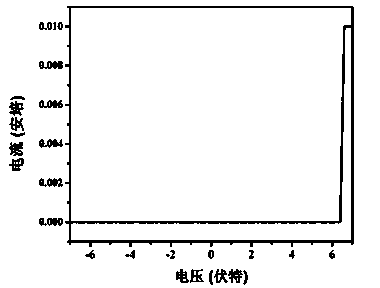

[0040] 1. Dispersion: Disperse 100μg of Cu nanowires with a diameter of 10nm and an average length of about 20μm in 100ml ethanol solution, and oscillate ultrasonically in an ultrasonic oscillator with a power of 10mW for 5 minutes; surface of the silicon wafer. Then place the silicon wafer at room temperature, and after the solvent evaporates, the one-dimensional nanomaterials can be dispersed on the silicon wafer; figure 1 As shown, the Cu nanowires dispersed on the silicon wafer were magnified by 5000 times, 8000 times and 100000 times, respectively, as shown in the SEM images figure 1 Shown in a-c; its perspective electron microscope picture is shown in figure 1 Shown in d. It shows that the Cu nanowires are dispersed on the silicon wafer, which is convenient for the pick-up of the subsequent single-track nanowires;

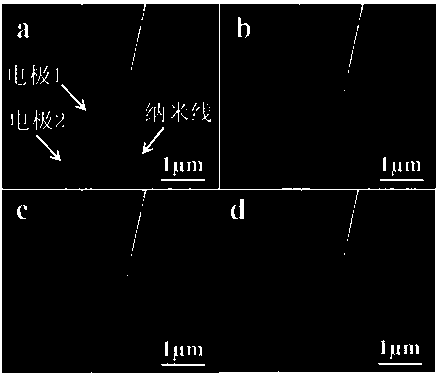

[0041] 2. Selection: Under the scanning electron microscope, select a Cu nanowire, use the nano-manipulation probe to pick it up and transfer it to ano...

Embodiment 2

[0048] 1. Dispersion: Disperse 100 μg of Cu nanotubes with a diameter of 15 nm and an average length of about 5 μm in 50 ml of water, and oscillate ultrasonically for 15 minutes in an ultrasonic oscillator with a power of 10 mW. After the dispersion is uniform, take 10 μL of the dispersion and drop it on the surface of a clean silicon wafer. Then place the silicon wafer at room temperature, and after the solvent evaporates, the one-dimensional nanomaterials can be dispersed on the silicon wafer;

[0049] 2. Selection: Under the scanning electron microscope, select a Cu nanotube, use the nano-manipulation probe to pick it up and transfer it to another silicon wafer substrate with Ag electrodes, and place it on the place to be welded;

[0050] 3. Welding: Use two tungsten probe electrodes with a radius of curvature of 500nm, one of which is pressed on the surface of the Cu nanotube, and the other is pressed on the Ag conductive layer of the silicon wafer near the Cu nanowire, an...

Embodiment 3

[0053] 1. Dispersion: Disperse 200 μg of Ag nanowires with a diameter of 80 nm and an average length of about 15 μm in 10 ml of methanol, and oscillate ultrasonically for 30 minutes in an ultrasonic oscillator with a power of 30 mW. After the dispersion is uniform, take 10 μL of the dispersion and drop it on the surface of a clean silicon wafer. Then place the silicon wafer at room temperature, and after the solvent evaporates, the one-dimensional nanomaterials can be dispersed on the silicon wafer;

[0054] 2. Selection: Under the scanning electron microscope, select an Ag nanowire, use the nano-manipulation probe to pick it up and transfer it to another glass substrate with Ag electrodes, and place it on the place to be welded;

[0055] 3. Welding: Use two tungsten probe electrodes with a radius of curvature of 500nm, one of which is pressed on the surface of the Ag nanowire, and the other is pressed on the Ag conductive layer of the glass substrate near the nanowire, and ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com