An Outer Edge Welding Device for Hydraulic Cylinder Manufacturing

A welding device and hydraulic cylinder technology, applied in the field of hydraulic cylinder welding, can solve the problems of low efficiency, poor quality of manual welding and high cost, and achieve the effects of convenient operation, improved welding quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

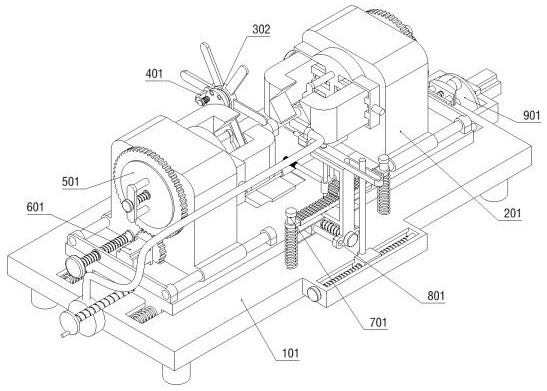

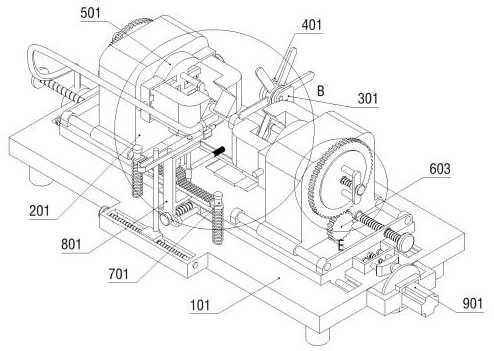

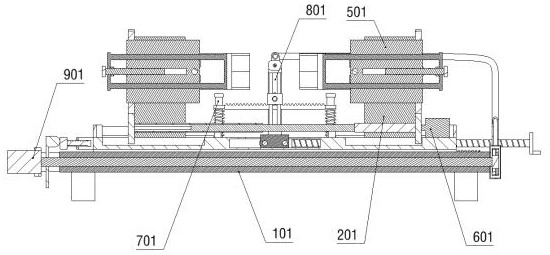

[0039] Example: please refer to Figure 1 to Figure 12 :

[0040] The invention provides an outer edge welding device for hydraulic cylinder manufacturing, which includes an installation support part 1; two sliding adjustment parts 2 are installed on the installation support part 1; the structures on the two sliding adjustment parts 2 are the same; The movable jamming device 3 is slidably connected to the movable jamming device 3; the elastic positioning device 4 is fixedly connected to the movable jamming device 3; A welding drive device 6 is installed; an elastic engaging part 7 is fixedly connected to the installation support part 1; a self-cleaning welding device 8 is fixedly connected to the movable clamping device 3; a ventilation drive device 9 is fixedly connected to the installation support part 1; the installation support Part 1 includes: installation support plate 101, adjustment screw 102, adjustment slide block 103, adjustment toggle lever 1031, drive reset shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com