Mucilage glue welding equipment for disposable mask production

A welding equipment and a one-time technology, applied in the application, sewing tools, clothing and other directions, can solve the problems of low efficiency, time-consuming and labor-consuming, and not strong enough for manual manual welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1

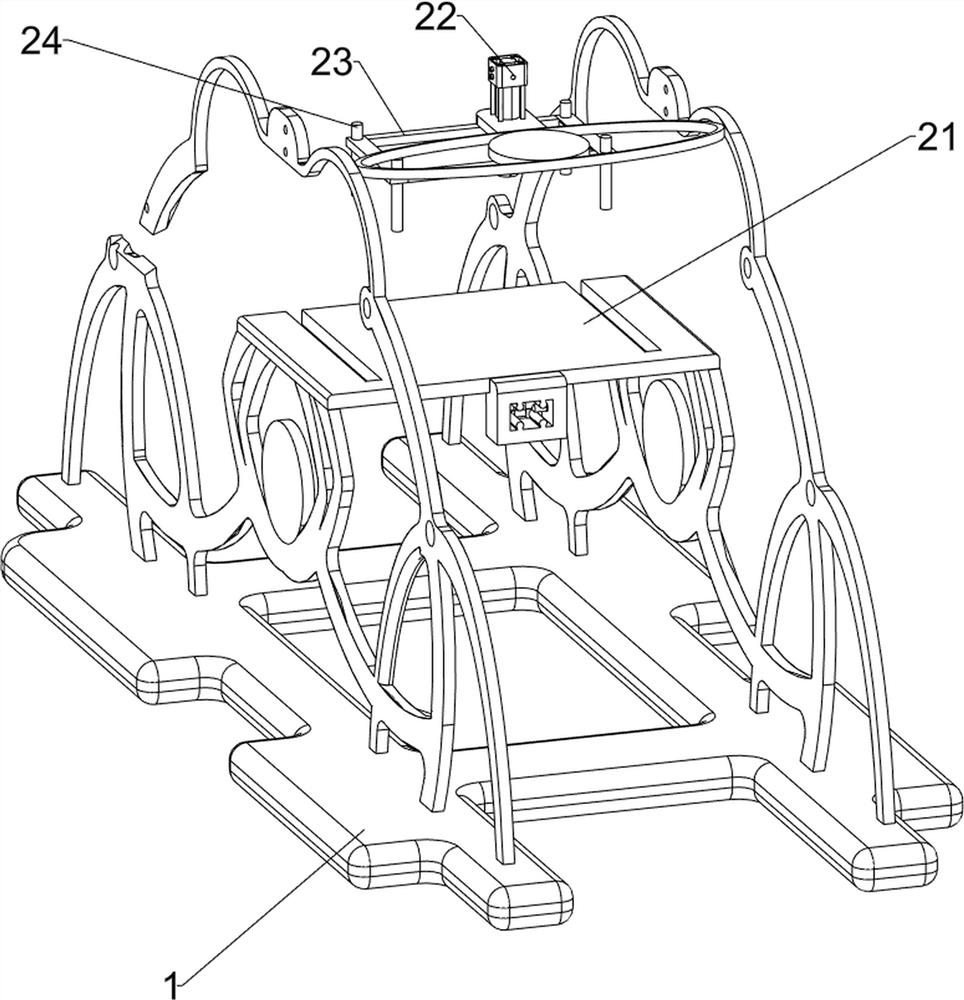

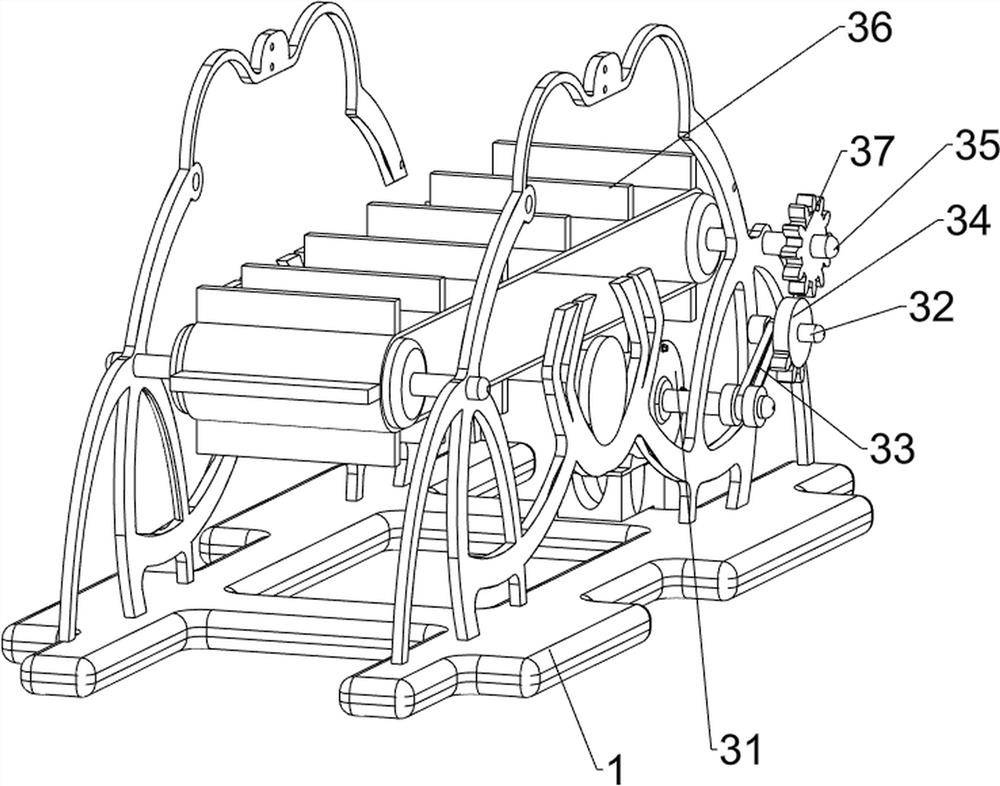

[0071] A kind of viscose welding equipment for the production of disposable masks, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a welding mechanism 2 and a transport mechanism 3. The bottom plate 1 is provided with a welding mechanism 2, and the bottom plate 1 is provided with a transport mechanism 3. The welding mechanism 2 cooperates with the transport mechanism 3.

[0072] When people need to carry out glue welding to the disposable mask, first people put the disposable mask in the conveying mechanism 3, then make the conveying mechanism 3 run, the conveying mechanism 3 makes the mask move forward intermittently, and people make the welding mechanism 2 run at the same time , when the disposable mask is located in the welding mechanism 2 and stops moving, people put the elastic drawstring on the top of the disposable mask, and the welding mechanism 2 carries out glue welding on it, and people continue to put the disposable mask i...

Embodiment 2

[0074] On the basis of Example 1, such as image 3 and Figure 4 As shown, the welding mechanism 2 includes a pressure bearing plate 21, a first cylinder 22, a mounting frame 23 and a welding rod 24. The upper middle part of the base plate 1 is provided with a pressure bearing plate 21, and the upper part of the base plate 1 is provided with a first cylinder 22. The first cylinder A mounting frame 23 is provided at the bottom of the mounting frame 22, and four welding rods 24 are arranged on the inside of the mounting frame 23, and the welding rods 24 are located above the pressure bearing plate 21.

[0075] People open the first cylinder 22, and the operation of the first cylinder 22 will cause the mounting frame 23 to move up and down repeatedly, and then the welding rod 24 will move up and down repeatedly. When the welding rod 24 moves downward, the disposable mask will move to the pressure plate 21 First, people put the elastic drawstring on the top of the disposable mask...

Embodiment 3

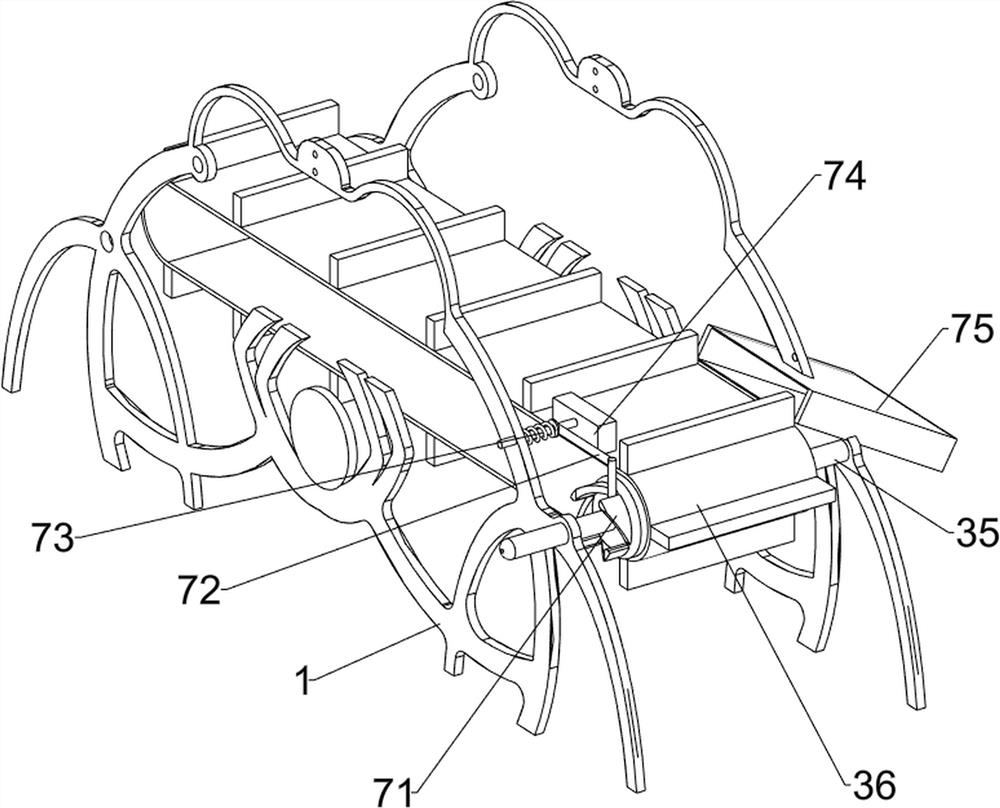

[0079] On the basis of Example 2, such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a pull cord mechanism 4 is also included, and the pull cord mechanism 4 includes a fixed block 41, a third rotating shaft 42, a pressing block 43, a first elastic assembly 44, a sheave 45, a moving plate 46, a second elastic assembly 47, Top block 48, reset assembly 49, turn block 410 and second cylinder 411, pressure bearing plate 21 top side, rear, left and right sides are all provided with fixed blocks 41 inside, bottom plate 1 upper side, rear, left and right sides are all rotatably provided with The third rotating shaft 42, the third rotating shaft 42 on the left and right sides is equipped with a rope pulley 45, the top of the fixed block 41 on the left and right sides has two first elastic components 44, and the two first elastic components 44 on the same fixed block 41 A briquetting block 43 is slidably connected between the components 44, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com