Diesel oil heating oil quantity sensor

An oil quantity sensor and diesel heating technology, applied in the field of oil quantity sensor, can solve the problems of lower reliability of the fuel tank, many openings, and many solder joints, etc., and achieve the effects of reducing production costs, improving reliability, and reducing solder joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

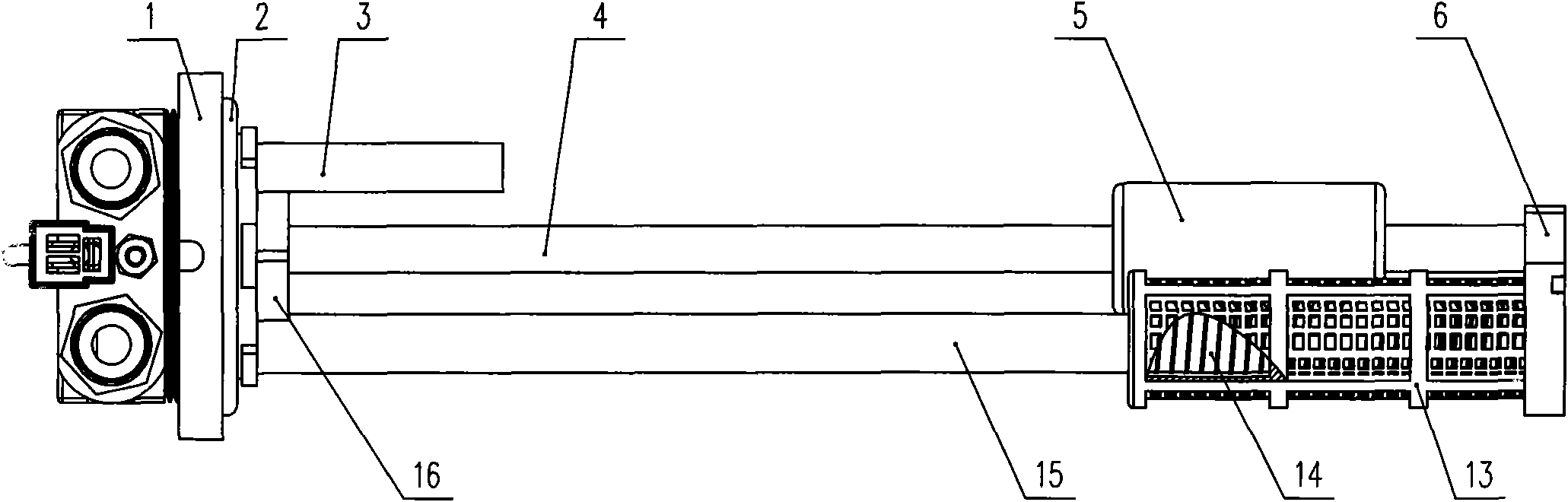

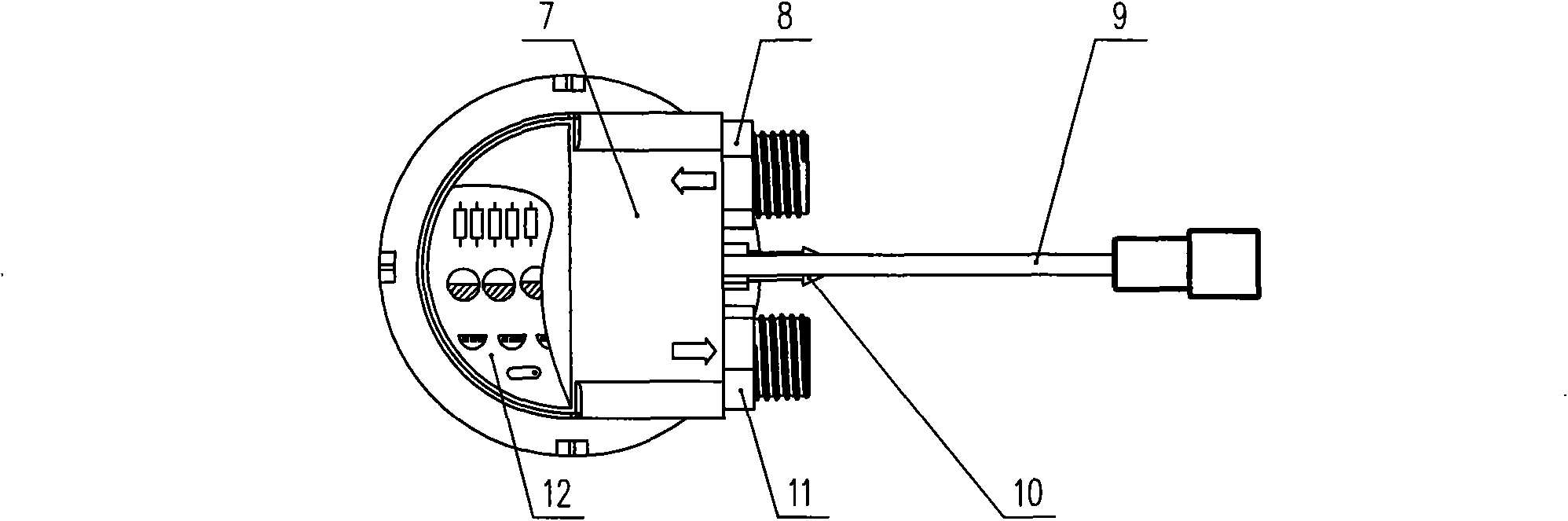

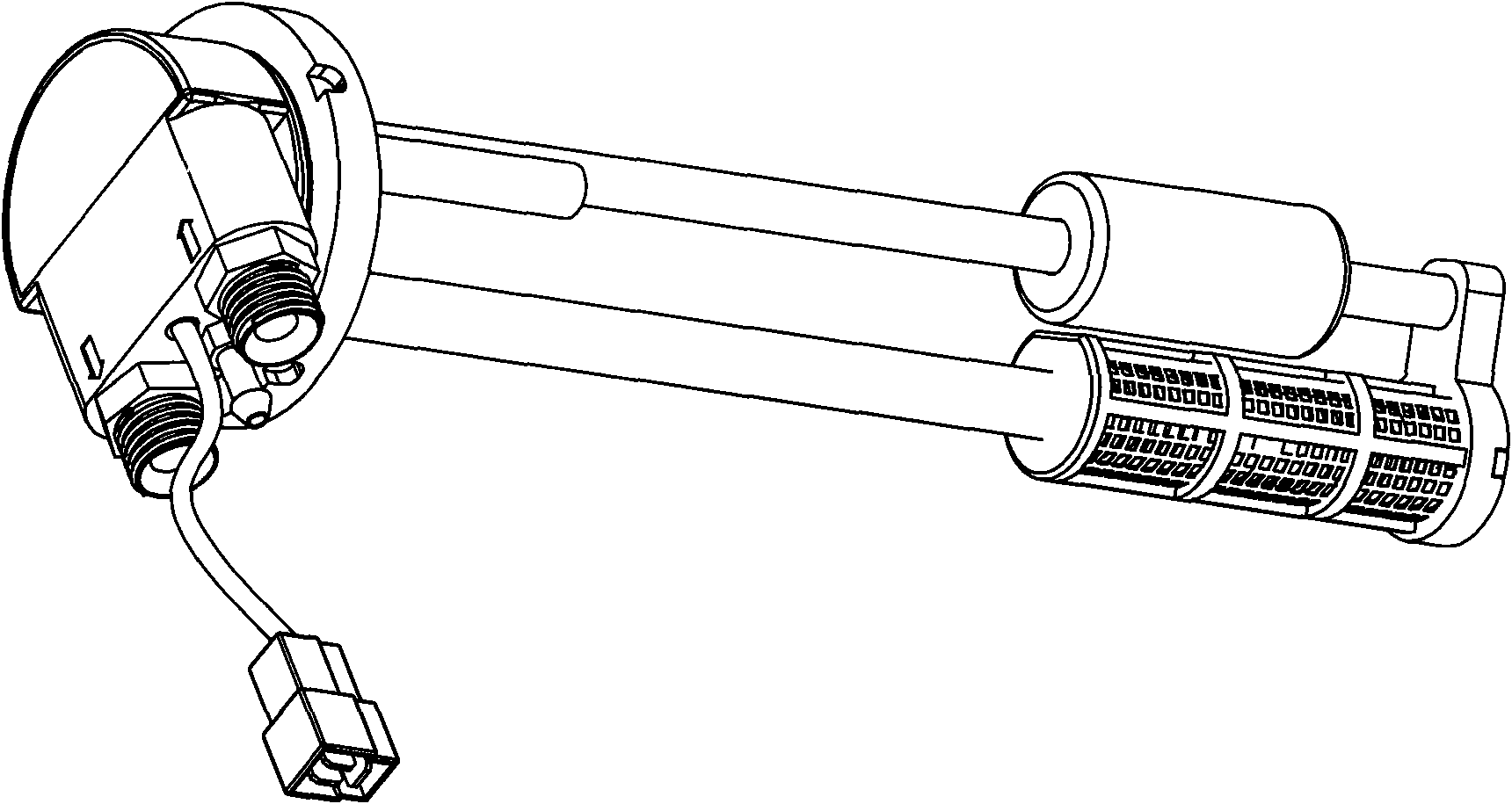

[0011] Such as figure 1 , 2 , 3, the present invention is further described as follows: diesel heating oil quantity sensor, comprises support 1, is connected with the data tube 4 that is evenly distributed with some reed tubes in the height direction on the support, and data tube 4 overcoats have can move up and down. The magnetic float 5 of the fuel tank is also connected to the oil tank oil inlet pipe 15 and the oil return pipe 3 on the support, and the oil tank oil inlet pipe 15 and the oil return pipe 3 respectively pass through the oil circuit inside the support and the oil outlet interface 11 of the support and the oil return interface 8 of the support connected; the head of the oil inlet pipe of the fuel tank is connected with a filter screen 13 and a temperature sensor through a plug 6, and an electric heating body 14 is arranged in the oil inlet pipe of the fuel tank; the intelligent heating circuit control board 12 is directly installed in a chamber on the support, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com