Fiber Bragg grating strain sensor

A grating strain and sensor technology, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of small measurement range of strain sensors and complicated installation process, and achieve the effect of small solder joints, not easy to fall off, and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, but are only examples to make the advantages of the present invention more clear and easy to understand. Fixed structure, sealing interface and supporting base.

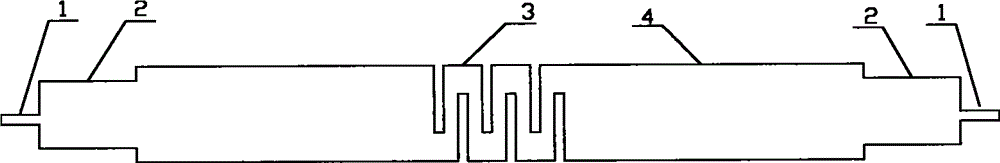

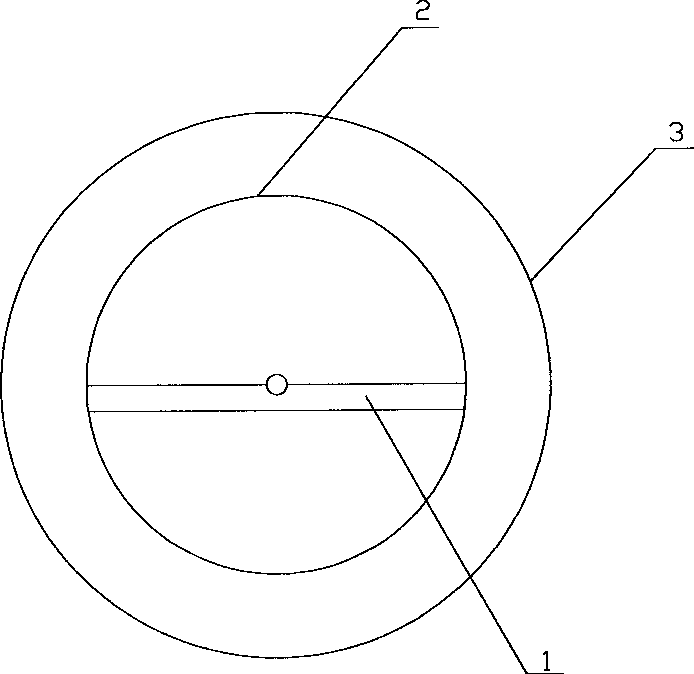

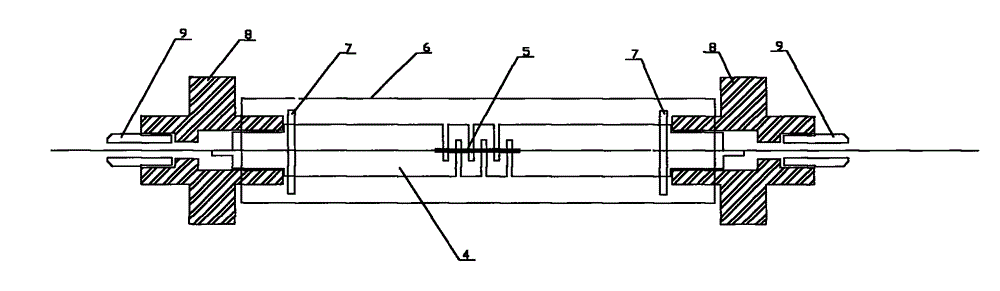

[0021] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the fiber Bragg grating strain sensor includes an elastic structure 4 with holes alternately spaced, a fiber Bragg grating 5, a protective sleeve 6, a sealing ring 7, a fixed structure 8, and a sealing interface 9; the elastic structure 4 includes an elastic region 3, a metal sheet 1 and thread 2, and the elastic area 3, metal sheet 1 and thread 2 are integrated structures; the cavities constituting the elastic area 3 are perpendicular to the central axis of the cylinder, and cross the central axis of the cylinder, and are distributed in the elastic in a staggered manner. Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com