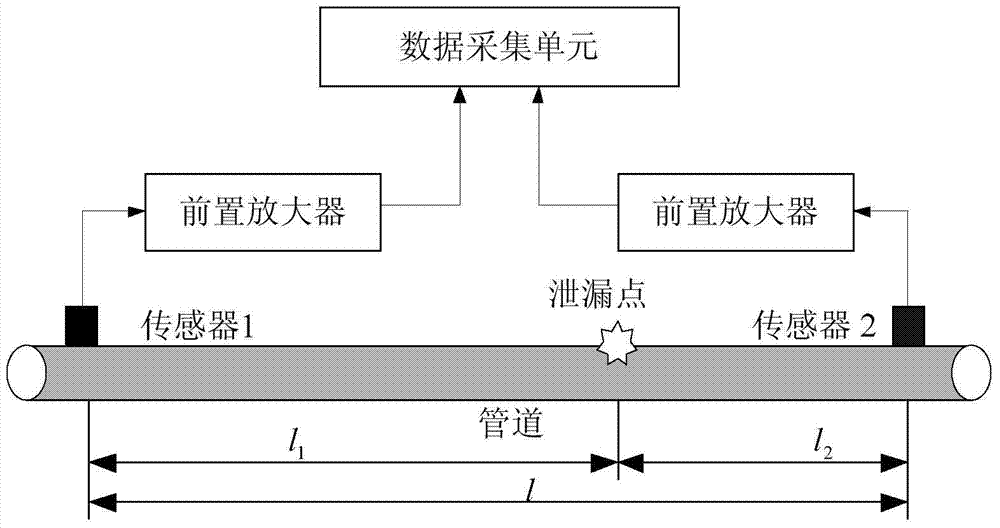

Fluid conveying pipe leakage acoustic emission time-frequency positioning method

A pipeline leakage and positioning method technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of large positioning error, weak signal correlation, and large time delay estimation error, etc., to solve the positioning error big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

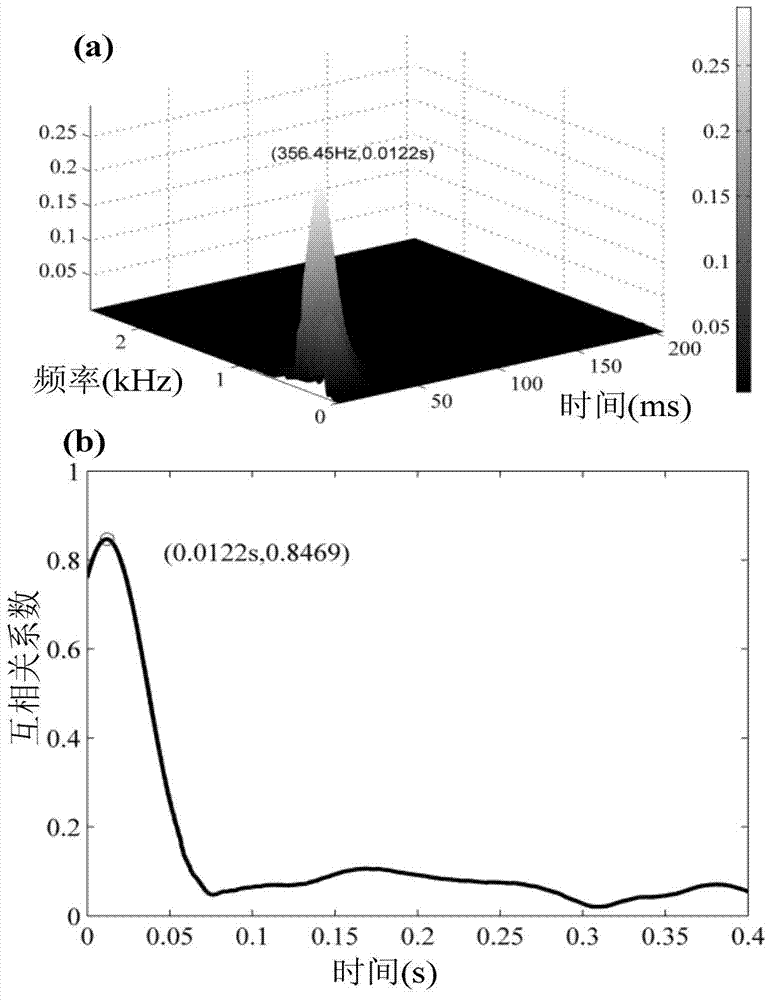

[0054] The pipeline leakage acoustic emission time-frequency positioning method proposed by the present invention is applied to the gas pipeline leakage detection experimental platform, wherein the total length of the pipeline is 110m, the air pressure is within 0.2MPa, and the geometric and material parameters of the pipeline are as shown in Table 1:

[0055] Table 1 Pipeline geometry and material parameters used in experiments

[0056]

[0057] In the table, a and b are the inner diameter and outer diameter of the pipe respectively; μ and ρ are the Poisson’s ratio and density of the pipe wall material respectively; G and E are the shear modulus and Young’s modulus of the pipe wall material respectively; c 0 is the rod speed corresponding to the tube wall material,

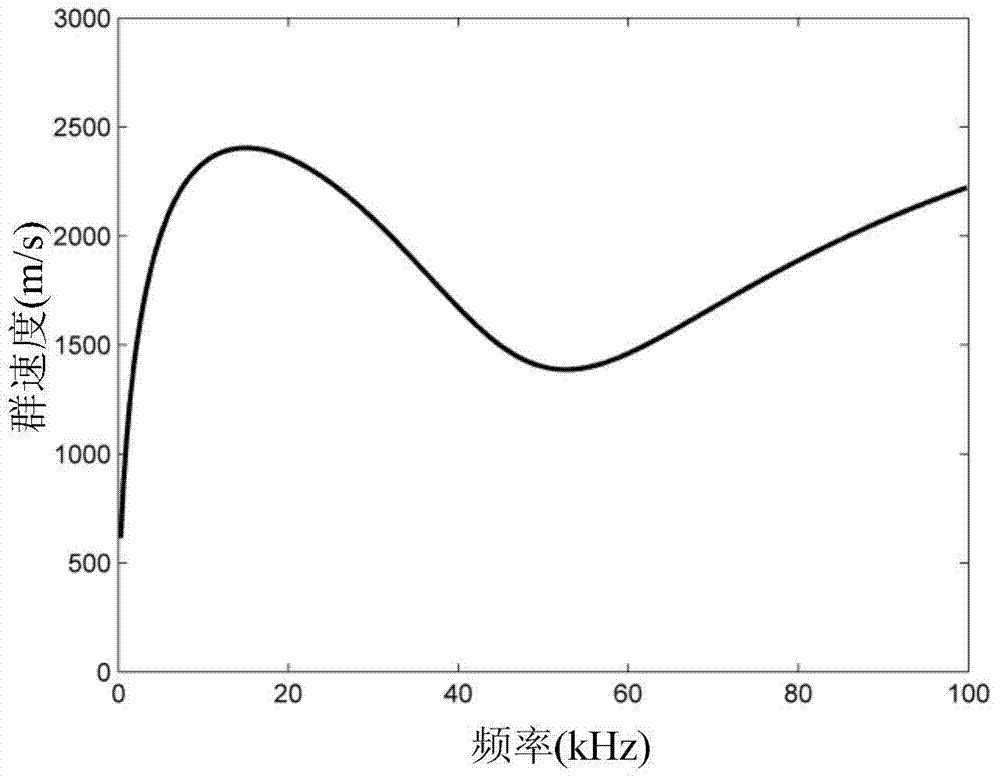

[0058] Using the geometric structure and material parameters of the pipeline, the numerical solution of the pipeline dispersion equation can be obtained, and the group velocity dispersion curve is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com