Prop porcelain insulator and porcelain bushing ultrasonic wave detecting method

A pillar ceramic insulator, pillar insulator technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of small sand and small gaps, achieve enhanced detection function, reduce instrument adjustment procedures, and prevent missed detection and misjudgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

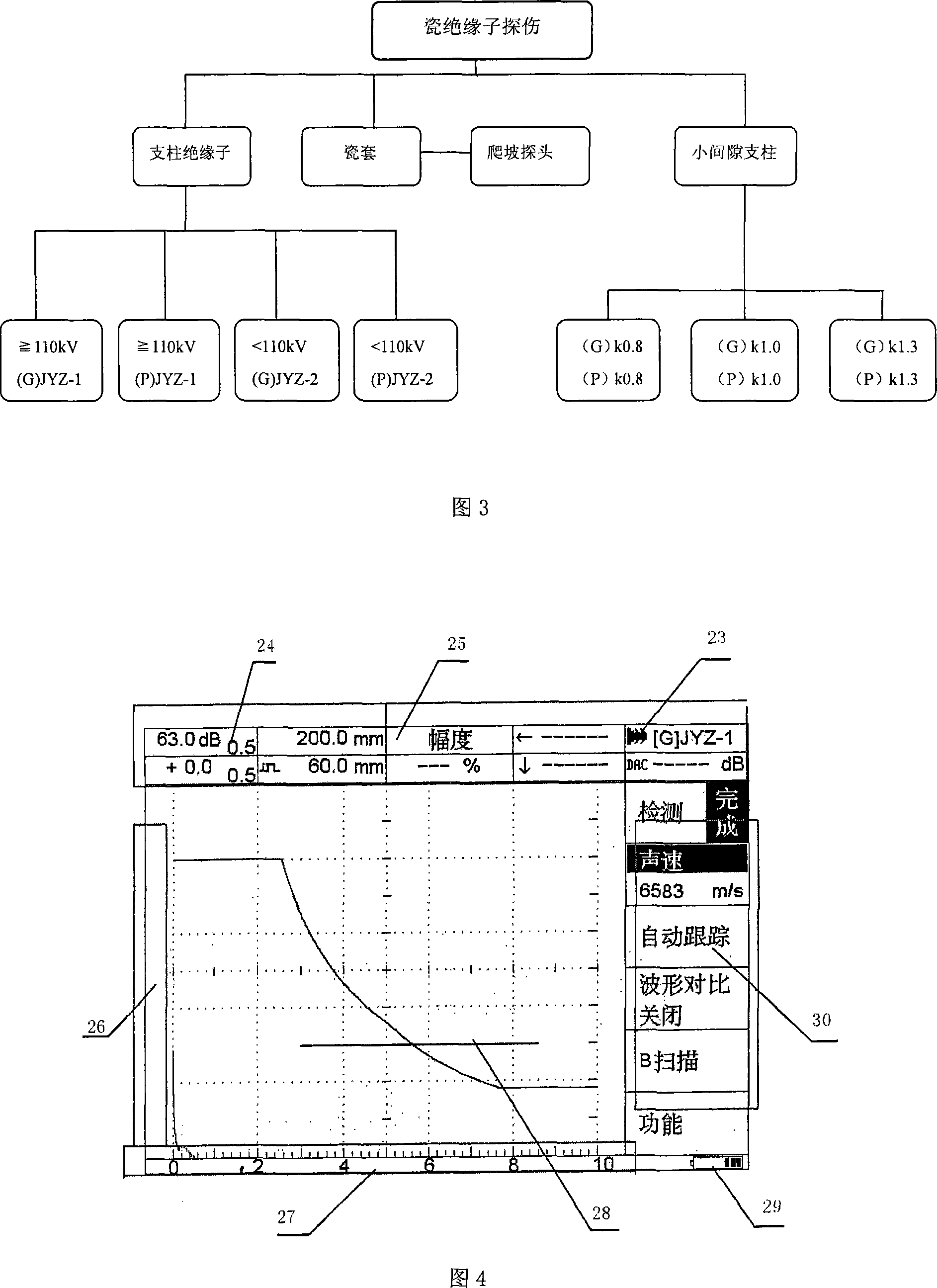

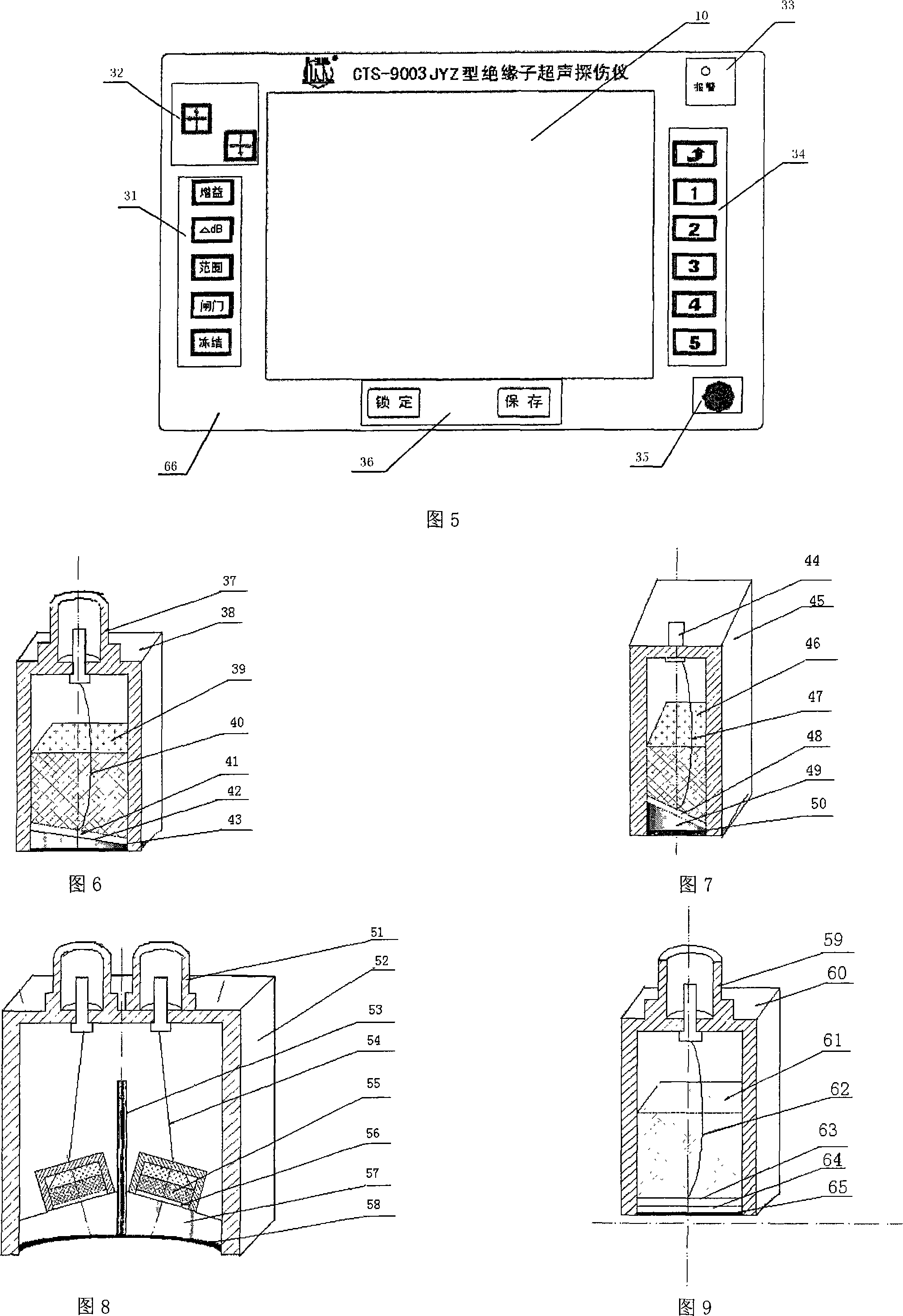

[0102] Flaw detection operation Porcelain insulator flaw detection is divided into three types according to the detection object: pillar porcelain insulator, porcelain sleeve, and small gap pillar. As shown in Figure 3.

[0103] This embodiment is for flaw detection of post insulators, and small-angle longitudinal wave probe 3 is used for flaw detection of post insulators

[0104] (1) Press the light touch power switch key 35 on the panel 66 of the pillar porcelain insulator and porcelain sleeve ultrasonic intelligent detector 1, open the pillar porcelain insulator and porcelain sleeve ultrasonic intelligent detector 1, and a start-up screen appears, as shown in Figure 1, press Press any key to enter the detection interface; in the submenu key 34 of the panel 66, press the pillar porcelain insulator key, namely the 1 key, to select the pillar insulator, as shown in Figure 13;

[0105] (2) Measure the sound velocity Insert the sound velocity probe 2 into the R socket of the pi...

Embodiment 2

[0115] This embodiment is for flaw detection of porcelain bushings.

[0116] (1) Press the light touch power switch key 35 on the panel 66 to turn on the pillar porcelain insulator and porcelain sleeve ultrasonic intelligent detector 1, and a start-up screen appears, as shown in Figure 1, press any key to enter the detection interface, as shown in Figure 13 ;

[0117] (2) Press the 2 key in the submenu key 34 of the panel 66 to select the porcelain sleeve and enter the porcelain sleeve detection interface;

[0118] (3) Insert the creeping wave probe 5 plug into the R jack of the tester 1, connect the creeping wave probe 5 with the pillar porcelain insulator and the porcelain sleeve ultrasonic intelligent detector 1; enter the porcelain sleeve detection interface, and the porcelain sleeve detection does not distinguish between high-strength porcelain Or ordinary porcelain, so the sound velocity measurement function is not set, the interface sound velocity value is 6000m / s by d...

Embodiment 3

[0124] This embodiment is for flaw detection of pillar porcelain insulators with small gaps.

[0125] (1) Press the light touch power switch key 35 on the panel 66 of the pillar porcelain insulator and porcelain sleeve ultrasonic intelligent detector 1, open the pillar porcelain insulator and porcelain sleeve ultrasonic intelligent detector 1, and a start-up screen appears, as shown in Figure 1; press Press any key to enter the detection interface, as shown in Figure 13; in the submenu key 34 on the panel 66, press the small gap pillar porcelain insulator key, that is, the 3 key, and select the small gap pillar insulator;

[0126] (2) Measure the sound velocity and enter the flaw detection interface of the small gap pillar insulator; insert the plug of the sound velocity measuring probe 2 into the R jack of the detector 1, connect the sound velocity measuring probe and the detector; input the actual perimeter of the small gap pillar insulator to be tested, Couple the sound vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com