Surface acoustic wave transducer with transverse mode suppression function and preparation method thereof

A surface acoustic wave and transducer technology, applied in electrical components, impedance networks, etc., can solve the problems of increasing the insertion loss of SAW devices, affecting the performance of SAW devices, and large insertion loss, achieving easy large-scale promotion, performance improvement, The effect of in-band fluctuation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a surface acoustic wave transducer with a transverse mode suppression function, comprising the steps of:

[0038]Step 1. Obtain the piezoelectric substrate 1 and clean the surface. Piezoelectric substrate 1 uses 128°YX-LiNbO with high electromechanical coupling coefficient 3 wafer.

[0039] Step 2, preparing an interdigital transducer on the piezoelectric substrate 1 by photolithography, evaporation, stripping and other processes.

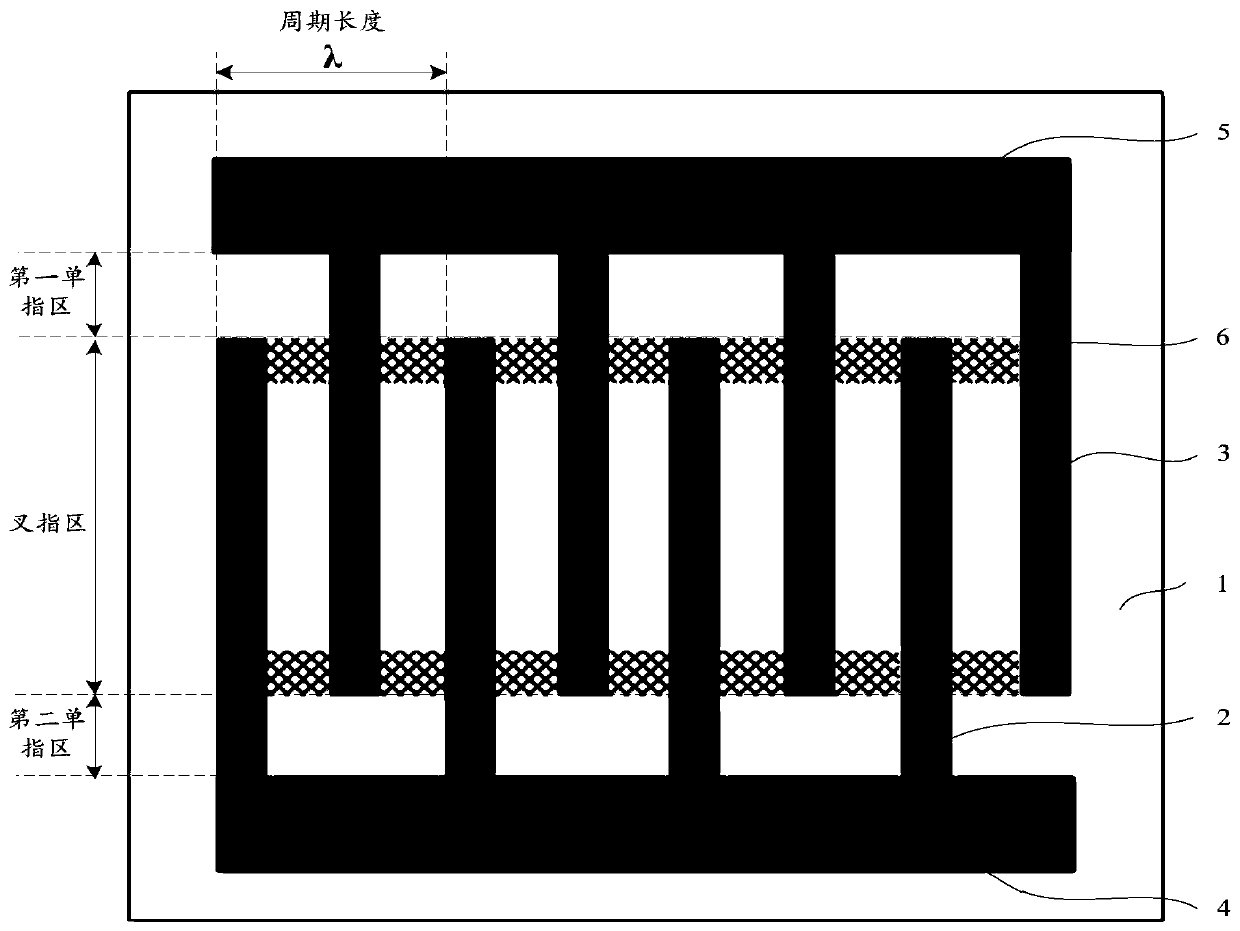

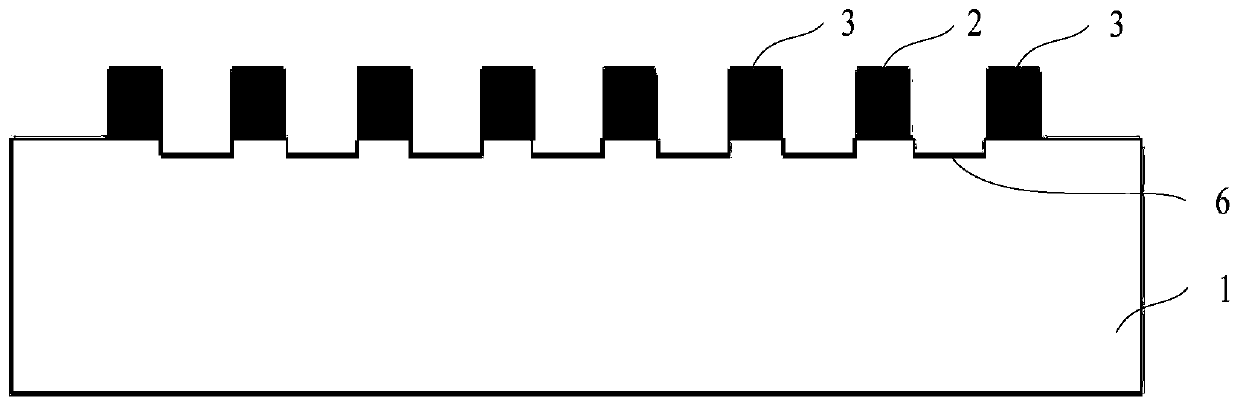

[0040] Specifically, combine Figure 1-Figure 2 As shown, the interdigital transducer includes a first interdigital electrode 2 and a second interdigital electrode 3 that are oppositely arranged, and a first bus bar 4 connected to the comb handle of the first interdigital electrode 2 and connected to the second interdigital electrode. The second bus bar 5 connected to the comb handle of the interdigital electrode 3 , each interdigital electrode is respectively placed between two adjacent electrode fingers of another...

Embodiment 2

[0046] A method for preparing another surface acoustic wave transducer with a transverse mode suppression function, comprising the following steps:

[0047] Step 1. Obtain the piezoelectric substrate 1 and clean the surface. A 36° quartz wafer with a high electromechanical coupling coefficient is used for the piezoelectric substrate 1 .

[0048] Step 2, preparing an interdigital transducer on the piezoelectric substrate 1 through processes such as evaporation, photolithography, and corrosion.

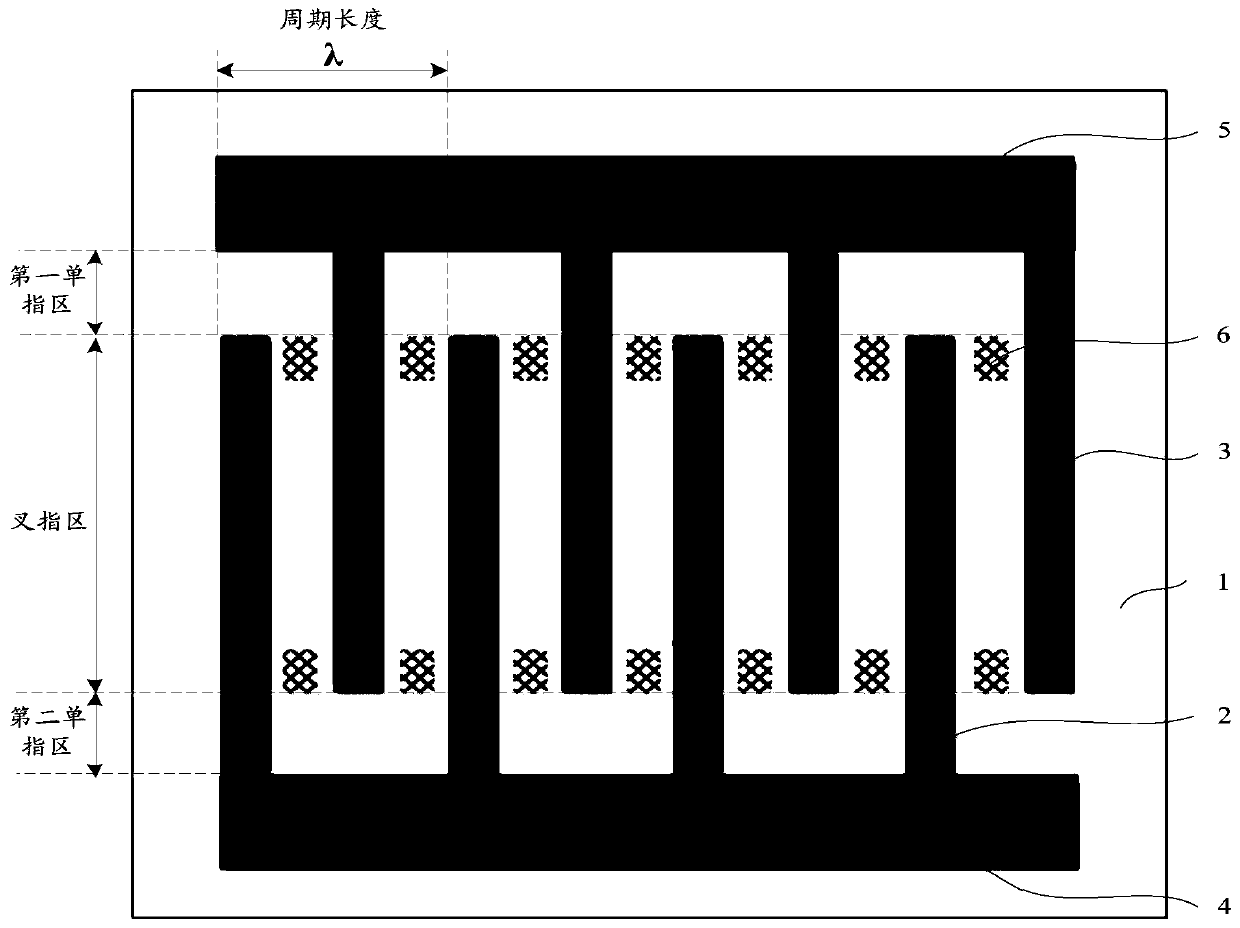

[0049] Specifically, combine Figure 3-Figure 4 As shown, the interdigital transducer includes a first interdigital electrode 2 and a second interdigital electrode 3 that are oppositely arranged, and a first bus bar 4 connected to the comb handle of the first interdigital electrode 2 and connected to the second interdigital electrode. The second bus bar 5 connected to the comb handle of the interdigital electrode 3 , each interdigital electrode is respectively placed between two adjac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cycle length | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com