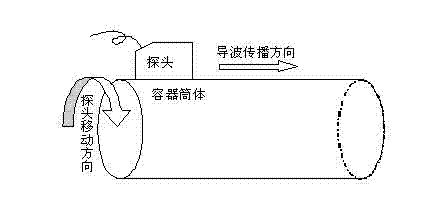

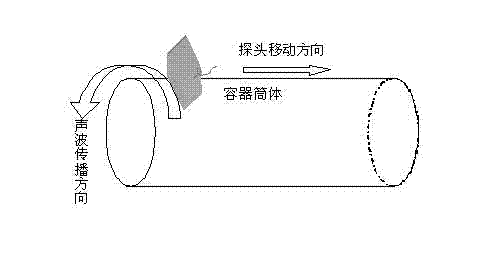

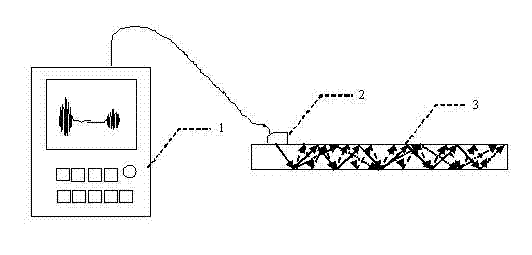

Integral ultrasonic guide wave detecting method for barrel of pressure vessel

A technology for pressure vessels and ultrasonic guided waves, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves. Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: In the embodiment of the present invention, longitudinal ultrasonic guided wave testing is performed on a pressure vessel cylinder with a specification of Φ400×10mm and a material of 20R. The firstly calculated longitudinal guided wave phase velocity and group velocity dispersion diagrams are respectively Figure 4 , Figure 5 . Depend on Figure 5 It can be seen that when the frequency of the ultrasonic guided wave exceeds 70KHz, the group velocity of the guided wave of the mode corresponding to the A curve changes little, which facilitates the positioning of the echo. When the frequency exceeds 200KHz, guided waves of other modes will be generated. On the one hand, it will cause clutter, and on the other hand, it will also reduce the energy of the guided wave of the mode corresponding to the A curve, resulting in a decrease in the signal-to-noise ratio during detection. Therefore, the guided wave frequency is determined as 70KHz ~ 200KHz. Different inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com