Device and method for rapidly testing comprehensive mechanical properties of anchor bolt

A technology of comprehensive mechanics and testing devices, applied in the direction of using stable torsion to test the strength of materials, etc., can solve the problems of large workload, long cycle, no applicable methods and special equipment for rapid testing of comprehensive performance of anchors, etc., to achieve comprehensive detection. , the detection results are intuitive and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

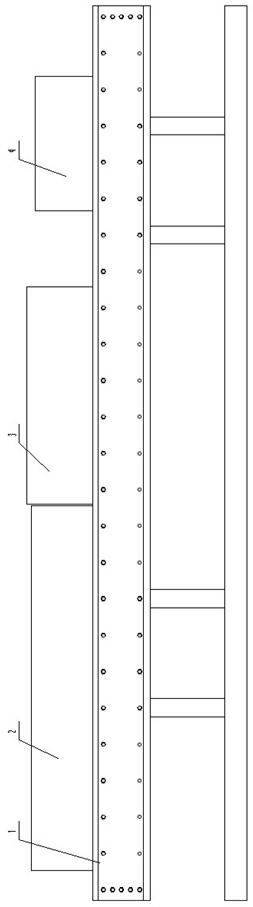

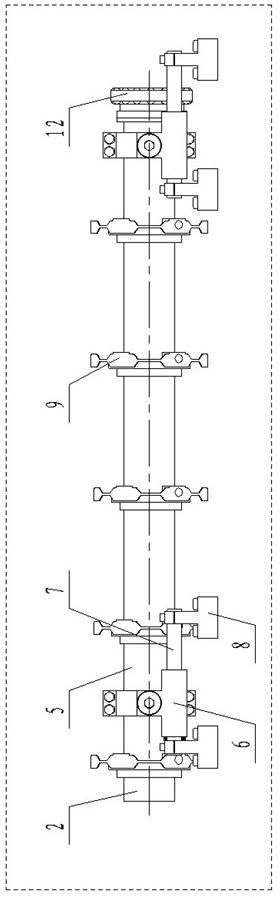

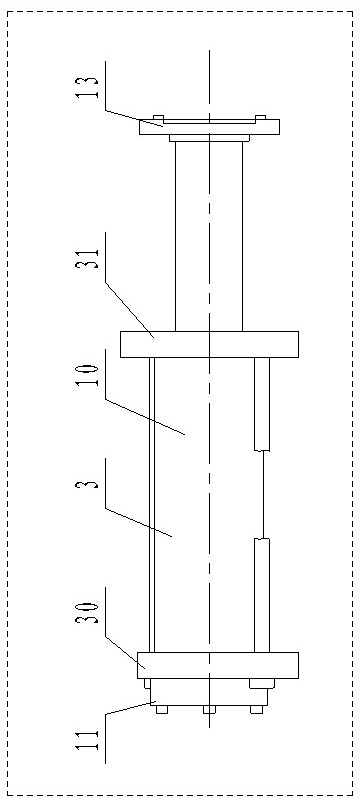

[0039] Such as Figure 1 to Figure 5 As shown, the rapid test device for the comprehensive mechanical properties of anchor rods includes: frame 1, universal centering device 2, axial force loading device 3 and hydraulic rotation power device 4, and universal centering device 2 is installed at one end of frame 1 , the axial force loading device 3 is installed in the middle of the frame 1, the hydraulic rotary power device 4 is installed on the other end of the frame 1, the axis of the universal centering device 2, the axis of the axis force loading assembly 3 and The axes of the hydraulic rotary power unit 4 are on a straight line;

[0040] The structure of the universal centering device 2 is as follows: the centering steel cylinder 5 is placed parallel to the frame 1, and a T-shaped sliding bracket 6 is provided at both ends of the centering steel cylinder 5, and the T-shaped Each slideway of the sliding bracket 6 is respectively provided with a sliding light rod 7, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com