Gas flow metering method

A metering method and gas flow technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as inaccurate flow values, achieve accurate real-time sound velocity c0, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

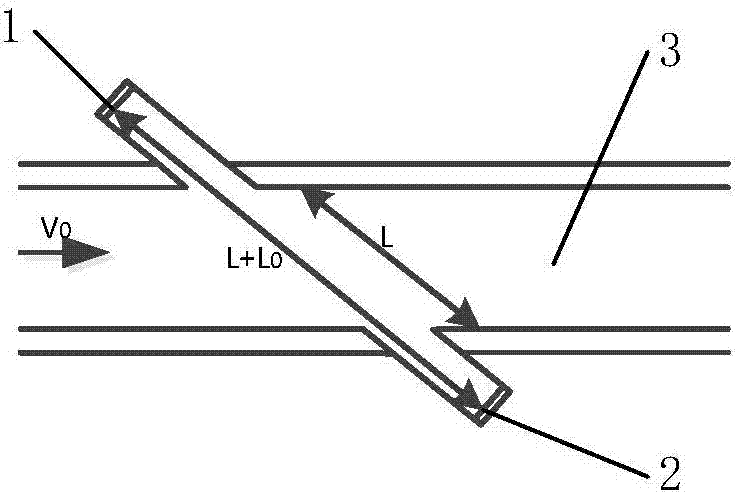

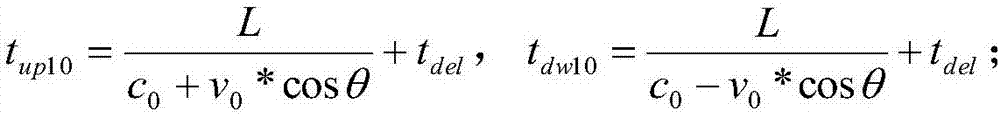

[0055] A method for measuring gas flow in this embodiment includes the following steps:

[0056] (S1) The sampling chip controls the first ultrasonic probe 1 so that the first ultrasonic probe 1 sends an ultrasonic signal to the second ultrasonic probe 2, and the sampling chip receives feedback from the second ultrasonic probe 2 according to the first ultrasonic probe 1 To the ultrasonic signal of the second ultrasonic probe 2, the uplink flight time t is obtained up10 ;

[0057] (S2) The sampling chip controls the second ultrasonic probe 2 so that the second ultrasonic probe 2 sends an ultrasonic signal to the first ultrasonic probe 1, and the sampling chip receives feedback from the first ultrasonic probe 1 according to the first ultrasonic probe. Ultrasonic signal from two ultrasonic probes 2 to the first ultrasonic probe 1 to obtain the downlink flight time t dw10 ;

[0058] (S3) according to the hardware delay time to the uplink flight time t up10 and downlink flight ...

Embodiment 2

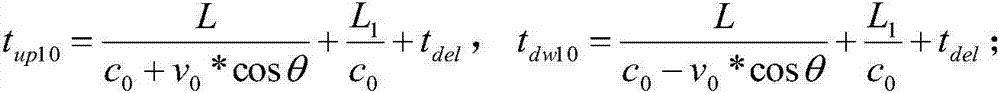

[0069] The difference between this embodiment and Embodiment 1 is that step (S3), i.e. the measuring method of the gas flow, comprises the following steps:

[0070] (S1) The sampling chip controls the first ultrasonic probe 1 so that the first ultrasonic probe 1 sends an ultrasonic signal to the second ultrasonic probe 2, and the sampling chip receives feedback from the second ultrasonic probe 2 according to the first ultrasonic probe 1 To the ultrasonic signal of the second ultrasonic probe 2, the uplink flight time t is obtained up10 ;

[0071] (S2) The sampling chip controls the second ultrasonic probe 2 so that the second ultrasonic probe 2 sends an ultrasonic signal to the first ultrasonic probe 1, and the sampling chip receives feedback from the first ultrasonic probe 1 according to the first ultrasonic probe. Ultrasonic signal from two ultrasonic probes 2 to the first ultrasonic probe 1 to obtain the downlink flight time t dw10 ;

[0072] (S3) For the obtained downli...

Embodiment 3

[0085] The difference between the present embodiment and the second embodiment also lies in the step (S3), that is, the metering method of the gas flow, which includes the following steps:

[0086] (S1) The sampling chip controls the first ultrasonic probe 1 so that the first ultrasonic probe 1 sends an ultrasonic signal to the second ultrasonic probe 2, and the sampling chip receives feedback from the second ultrasonic probe 2 according to the first ultrasonic probe 1 To the ultrasonic signal of the second ultrasonic probe 2, the uplink flight time t is obtained up10 ;

[0087] (S2) The sampling chip controls the second ultrasonic probe 2 so that the second ultrasonic probe 2 sends an ultrasonic signal to the first ultrasonic probe 1, and the sampling chip receives feedback from the first ultrasonic probe 1 according to the first ultrasonic probe. Ultrasonic signal from two ultrasonic probes 2 to the first ultrasonic probe 1 to obtain the downlink flight time t dw10 ;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com