Method and device for measuring compression coefficient and expansion coefficient of material on line

A technology of expansion coefficient and compression coefficient, which is applied in the field of material thermodynamic performance testing, can solve problems such as interference with normal use or production, failure to guarantee restoration to the original state, and difficult test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

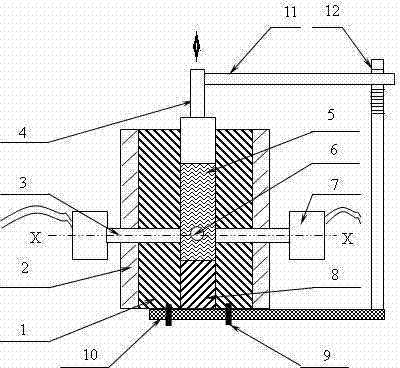

[0024] Implementation Case 1: Application figure 1 The schematic experimental device, change the temperature under the same pressure (60MPa), test the specific volume-ultrasonic sound velocity curve of polycarbonate (PC), such as Figure 4 As shown, is monotonic. Change the pressure, apply the device to get the lnv-T curve ( Figure 5 ), the slope of each point under different pressures is the coefficient of thermal expansion, such as Figure 7 ; Change the temperature and apply the device to obtain the lnv-P curve ( Image 6 ), the slope of each point at different temperatures is the isothermal compressibility coefficient, such as Figure 8 . In this way, the on-line detection of the ultrasonic sound velocity can obtain the specific volume, and then the expansion coefficient and compression coefficient can be obtained. Figure 9 The curves of polycarbonate thermal expansion coefficient α and ultrasonic sound velocity to temperature derivative under certain pressure are g...

Embodiment example 2

[0025] Implementation Case 2: Application figure 1 The illustrated experimental device obtains the relationship between the specific volume of polycarbonate and T, P, and the regression is the Tait equation of state:

[0026]

[0027]

[0028]

[0029] In the formula: v sp — specific volume, v sp0 —Specific volume under normal pressure, C — constant 0.0894, T tr —transition temperature at atmospheric pressure, b 1 ~b 4 -constant.

[0030] Fit the above three formulas step by step to obtain the constant value, b 1 =0.99996, b 2 =0.00089,b 3 =53.47053, b 4 =-0.00138. According to the definition of thermal expansion coefficient (α) and isothermal compression coefficient (β), the expressions of α and β can be obtained:

[0031] ,

[0032] In this way, the thermal expansion coefficient and isothermal compression coefficient can be obtained from the state equation, such as Figure 10 and 11 .

[0033] Of course, if the ultrasonic sound velocity is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com