Method for growing p-type AlGaN

A p-type, growth temperature technology, applied in the direction of sustainable manufacturing/processing, final product manufacturing, coating, etc., can solve the problems of difficult to obtain electrical conductivity, increase of dislocation density, high activation energy of Mg, and achieve improved surface morphology Appearance, increased luminous intensity, and reduced sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

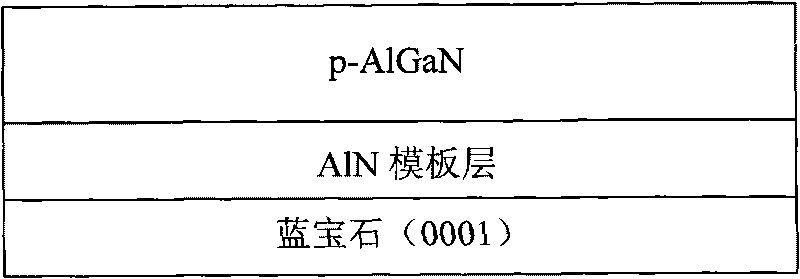

[0021] Such as figure 1 The preparation steps of the p-AlGaN sample shown are as follows:

[0022] 1) The temperature of the reaction chamber is raised to 1060°C, and the sapphire (0001) substrate is baked in a hydrogen atmosphere for 15 minutes;

[0023] 2) Raise the temperature of the reaction chamber to 1200°C, and directly grow a 320nm AlN thin film on the sapphire substrate as a template layer at a growth rate of 1.4 μm per hour. The growth conditions are: pressure 50torr, V / III 400;

[0024] 3) keep the growth temperature constant, on the basis of step 2), set the flow rate of TMI to be 200 sccm, Cp 2 The flow rate of Mg is 400sccm, using TMA, TMG, TMI, Cp 2 Mg and NH 3 At the same time, the method of entering the reaction chamber grows a p-AlGaN film with a thickness of 1 μm at a growth rate of 1 μm per hour, where the Al composition is set to 0.45, and the growth conditions are: pressure 75torr, V / III is 2000.

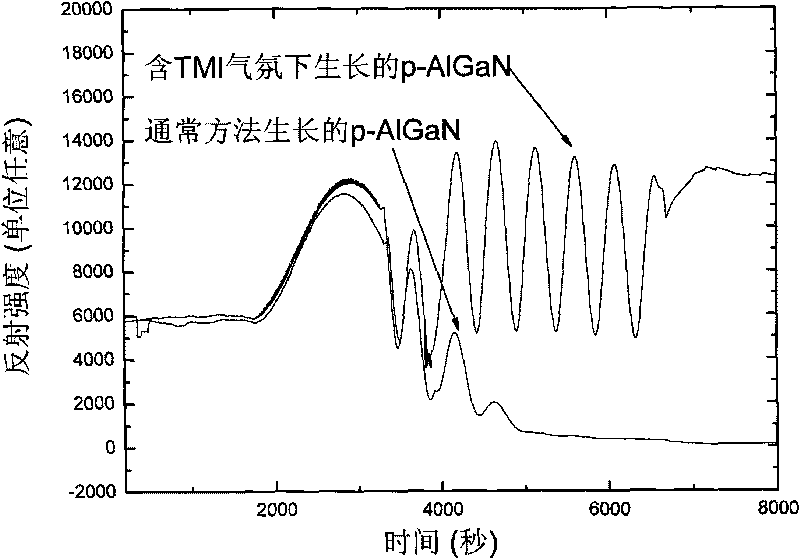

[0025] Compared with the p-AlGaN sample grown by the ...

Embodiment 2

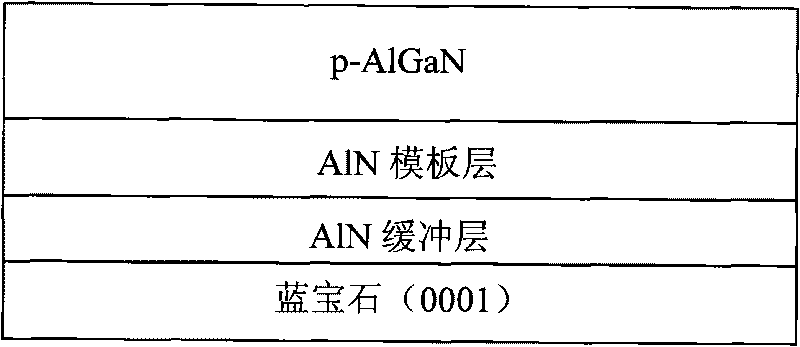

[0027] Such as image 3 The preparation steps of the p-AlGaN sample with the structure shown are as follows:

[0028] 1) The temperature of the reaction chamber is raised to 1060°C, and the sapphire (0001) substrate is baked in a hydrogen atmosphere for 15 minutes;

[0029] 2) Raise the temperature of the reaction chamber to 1200°C, and grow a 100-cycle AlN buffer layer on the sapphire substrate at a growth rate of 200nm per hour by pulsed atomic layer epitaxy, with a thickness of 100nm. The growth conditions are: pressure 150torr, V / III is 600, 5s TMA / 3s Hydrogen / 5s NH per cycle 3 / 3s hydrogen;

[0030] 3) Keep the temperature constant, grow a 320nm thick AlN film on the buffer layer as a template layer at a growth rate of 1.4 μm per hour, and the growth conditions are: pressure 50torr, V / III is 400;

[0031] 4) keep the growth temperature constant, on the basis of step 3), set the flow rate of TMI to be 120 sccm, Cp 2 The flow rate of Mg is 400sccm, using TMA, TMG, TMI,...

Embodiment 3

[0034] Such as Figure 5 The LED device with the structure shown, its preparation steps are as follows:

[0035] 1) The temperature of the reaction chamber is raised to 1060°C, and the sapphire substrate is heated and baked under a hydrogen atmosphere for 15 minutes;

[0036] 2) Raise the temperature to 1200°C, grow a 320nm thick AlN template layer, growth conditions: pressure 150torr, V / III is 600;

[0037] 3) Keeping the temperature constant, grow a 1 μm thick n-type AlGaN layer as a contact layer on the basis of step 2), wherein the Al component is 0.6, and the growth conditions are: pressure 75 torr, V / III is 1500, silane flow rate is 1 sccm;

[0038] 4) keep the temperature constant, and grow 3 cycles of Al on the basis of step 3)0.4 Ga 0.6 N / Al 0.25 Ga 0.75 N quantum well, the growth conditions are: pressure 75torr, V / III is 2000;

[0039] 5) Keeping the temperature constant, on the basis of step 4), a p-AlGaN electron barrier layer with a thickness of 10 nm is gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com