Environment-friendly adhesive and preparation method thereof

An adhesive and environmentally friendly technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of low adhesive viscosity and poor molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

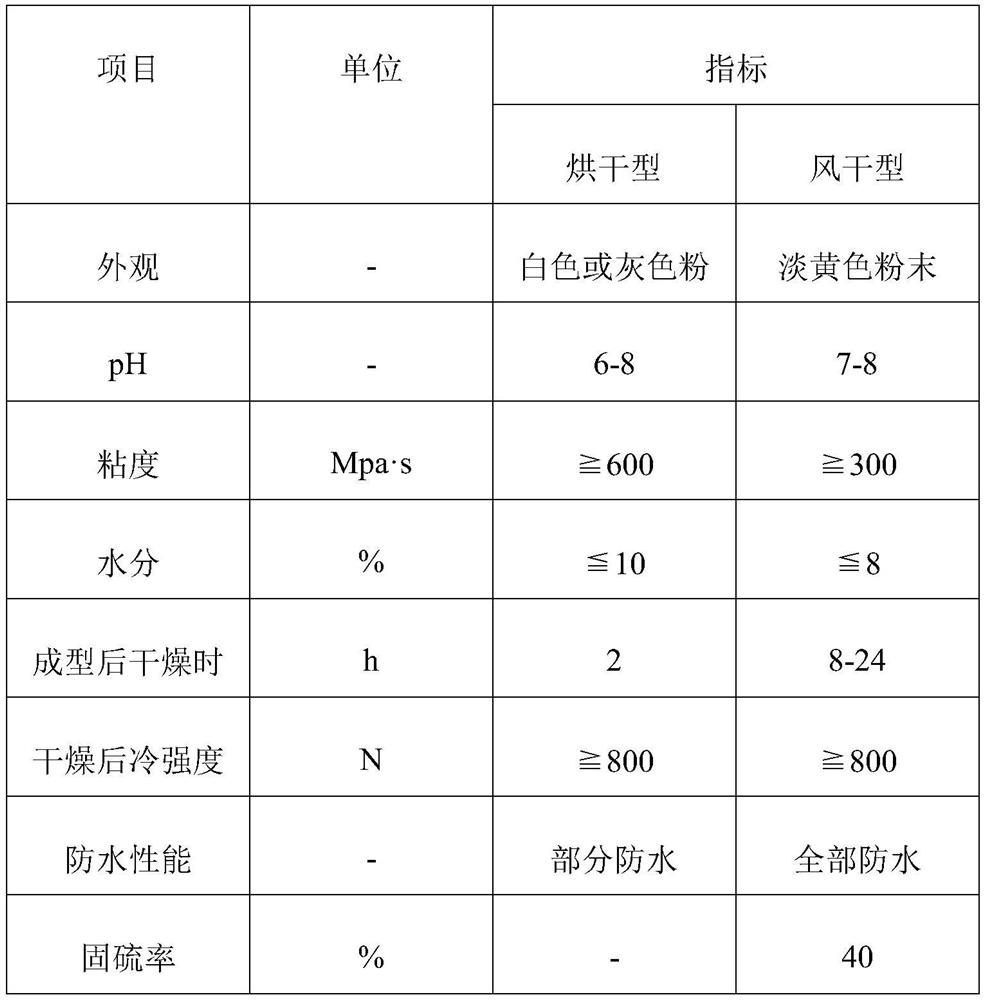

Image

Examples

preparation example Construction

[0032] A kind of preparation method of environment-friendly adhesive, comprises the following steps:

[0033] Mix polystyrene and dimethyl sulfoxide, add catalyst, and react at 80-90°C for 15-20 hours to obtain a prepolymer; mix sodium silicate and cellulose, add sodium methylene dinaphthalene sulfonate, and React at 100-120°C for 1-2 hours to obtain glue; vibrate and mix the prepolymer and bentonite, then add glue, stir and mix, extrude and dry.

[0034] Mix polystyrene and dimethyl sulfoxide, add a catalyst, and react at 80-90°C for 15-20 hours to obtain a prepolymer. The prepolymer is polysulfone resin, the catalyst can speed up the formation of polysulfone resin, and the preparation of polysulfone resin from polystyrene and dimethyl sulfoxide is more convenient, the preparation is more convenient, and it is more conducive to improving the production of environmentally friendly adhesives speed. At the same time, the prepared polysulfone resin has stronger surface activity...

Embodiment 1

[0045] An environmentally friendly adhesive, comprising the following raw materials: 40g polystyrene, 30g bentonite, 1g dimethyl sulfoxide, 5g cellulose, 10g sodium methylene dinaphthalene sulfonate and 5g sodium silicate.

[0046] A kind of preparation method of environment-friendly adhesive, comprises the following steps:

[0047] Mix polystyrene and dimethyl sulfoxide, then add aluminum trichloride, react at 80°C for 15 hours to obtain a prepolymer; mix sodium silicate and cellulose, add sodium methylene dinaphthalene sulfonate, React at ℃ for 1 hour to obtain the glue; vibrate and mix the prepolymer and bentonite, then add the glue, stir and mix, extrude, and dry.

Embodiment 2

[0049] An environmentally friendly adhesive, comprising the following raw materials: 60g polystyrene, 50g bentonite, 10g dimethyl sulfoxide, 15g cellulose, 20g sodium methylene dinaphthalene sulfonate and 18g sodium silicate.

[0050] A kind of preparation method of environment-friendly adhesive, comprises the following steps:

[0051] Mix polystyrene and dimethyl sulfoxide, then add ferric chloride, and react at 90°C for 20 hours to obtain a prepolymer; mix sodium silicate and cellulose, add sodium methylene dinaphthalene sulfonate, React at ℃ for 2 hours to obtain a glue solution; vibrate and mix the prepolymer and bentonite, then add the glue solution, stir and mix, extrude, and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com