Method of preparing low-dislocation density GaN thin film on Si substrate by adopting carbon nanotubes as periodic dielectric mask

A technology of carbon nanotubes and carbon nanotube arrays, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems related to compound polarity, damage to interface flatness, damage to crystal quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

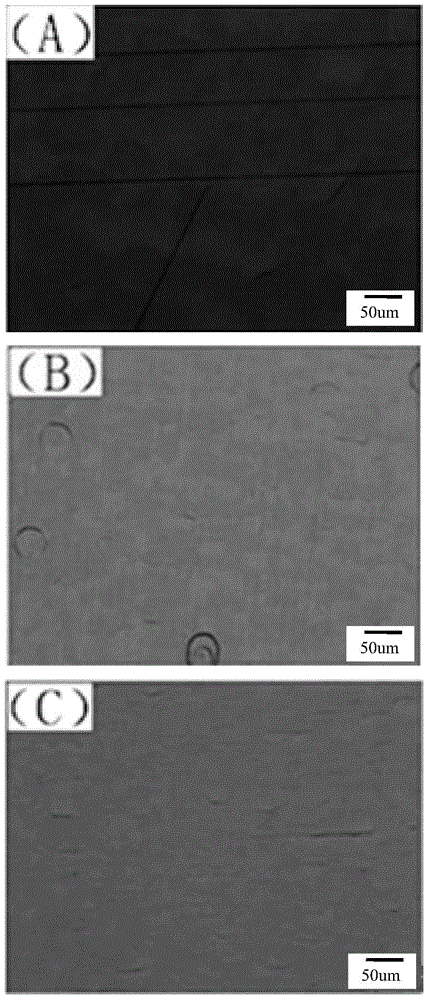

Image

Examples

Embodiment 1

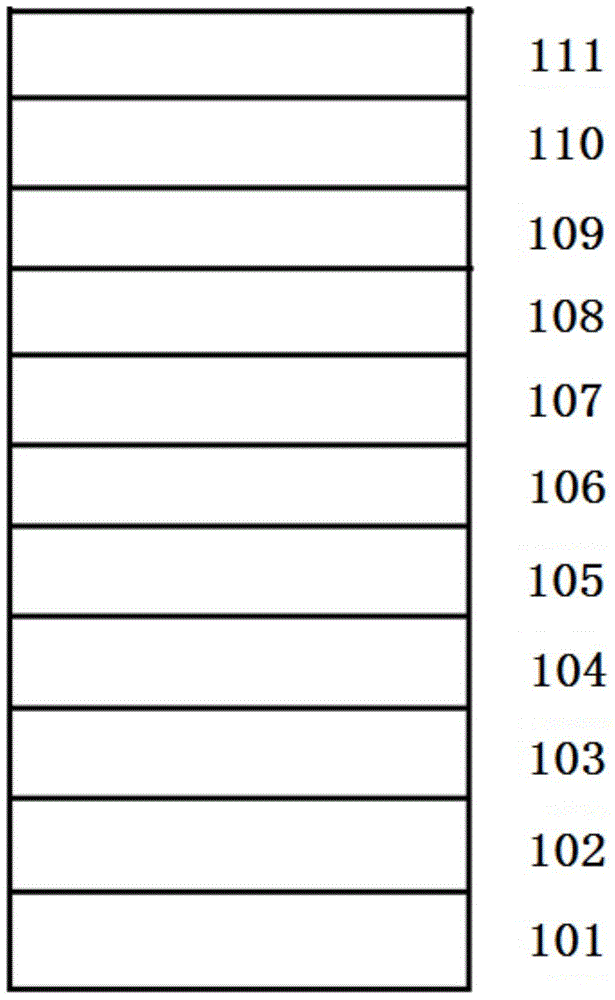

[0032] Use the product of Aixtron Company - tightly coupled vertical reaction chamber MOCVD growth system. During the growth process, trimethylgallium (TMGa) and trimethylaluminum (TMAl) were used as group III sources, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the Si substrate 101 was first heated to 1080° C. in the MOCVD reaction chamber, and the 2 Under the atmosphere, treat at high temperature for 5-10 minutes. Then in the metal organic compound vapor phase epitaxy reaction chamber, under hydrogen (H 2 ) atmosphere, temperature 1000℃~1500℃, reaction chamber pressure 50torr-100torr, take V / III ratio as 50~1000, feed TMAl as group III source, NH 3 As the V group source, on the Si substrate 101, grow a 0.1 micron thick AlN nucleation layer 102; adopt low-pressure chemical vapor deposition (LPCVD), use acetylene as the carrier gas, use Fe as the catalyst, on the AlN nucleation layer 10...

Embodiment 2

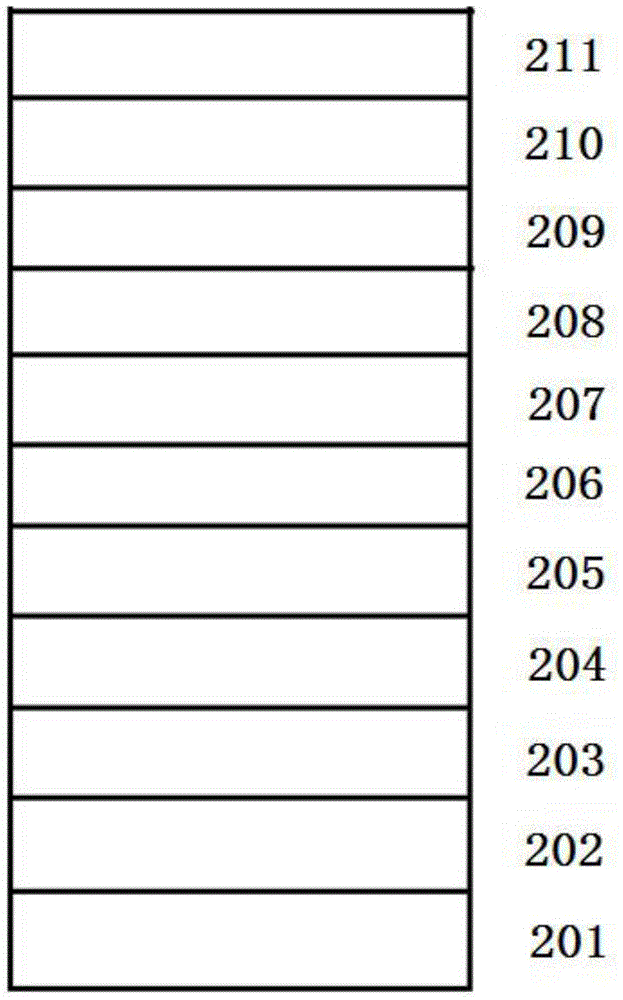

[0034]Use the product of Aixtron Company - tightly coupled vertical reaction chamber MOCVD growth system. During the growth process, trimethylgallium (TMGa) and trimethylaluminum (TMAl) were used as group III sources, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the Si substrate 201 was first heated to 1080° C. in an MOCVD reaction chamber, and 2 Under the atmosphere, treat at high temperature for 5-10 minutes. Then in the metal organic compound vapor phase epitaxy reaction chamber, under hydrogen (H 2 ) atmosphere, temperature 1000℃~1500℃, reaction chamber pressure 50torr-100torr, take V / III ratio as 50~1000, feed TMAl as group III source, NH 3 As a V group source, on a Si substrate 201, grow a 0.3 micron thick AlN nucleation layer 202; use low-pressure chemical vapor deposition (LPCVD) to grow neatly arranged four-layer unidirectional (crossed) carbon nanotubes. In the growth process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com