Method for MOVCD growth nitride epitaxial layer

A technology of nitride epitaxial layer and growth temperature, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of reducing the quality of epitaxial wafers, easily forming damaged layers and pollution on the surface of sapphire substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

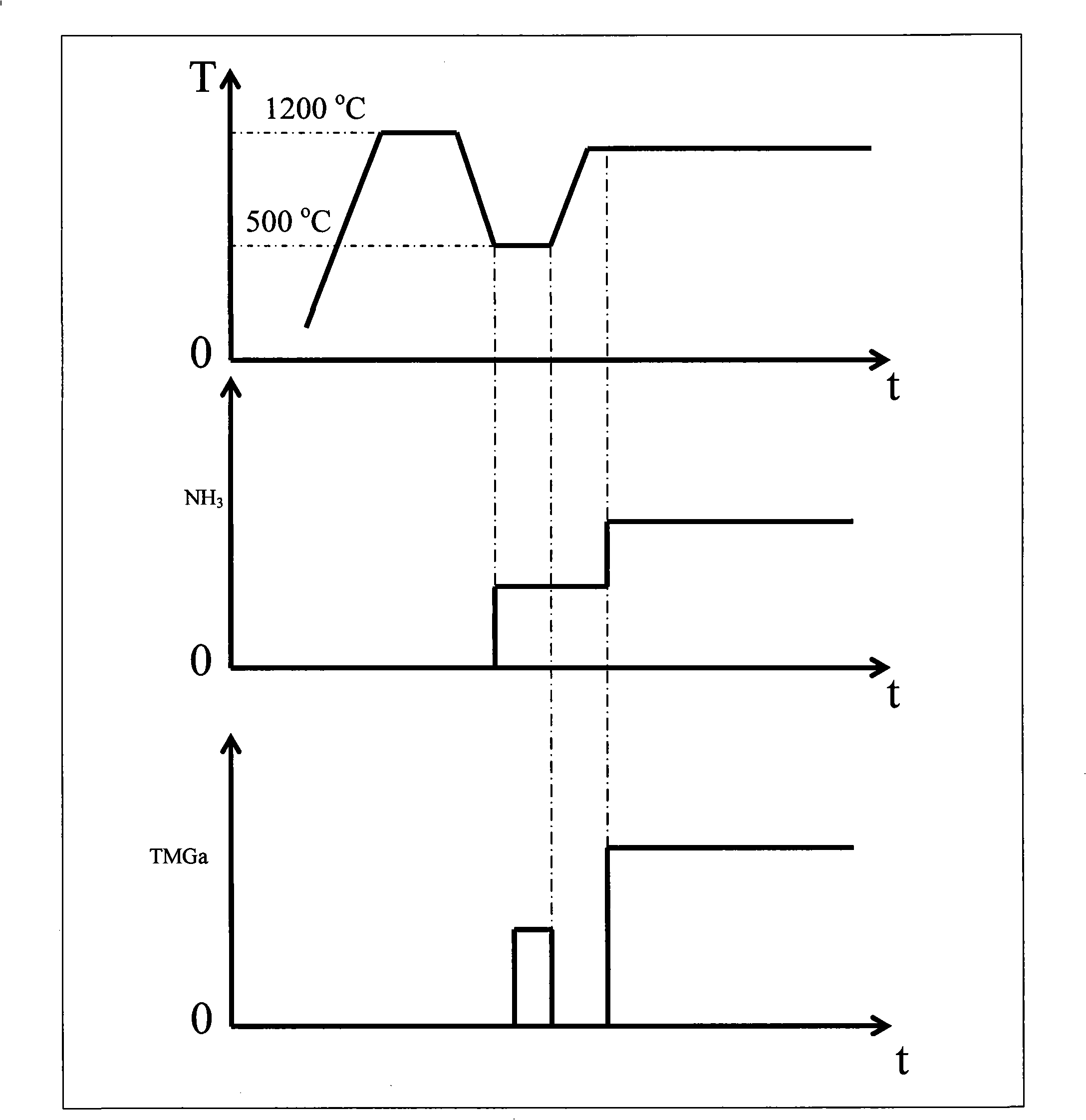

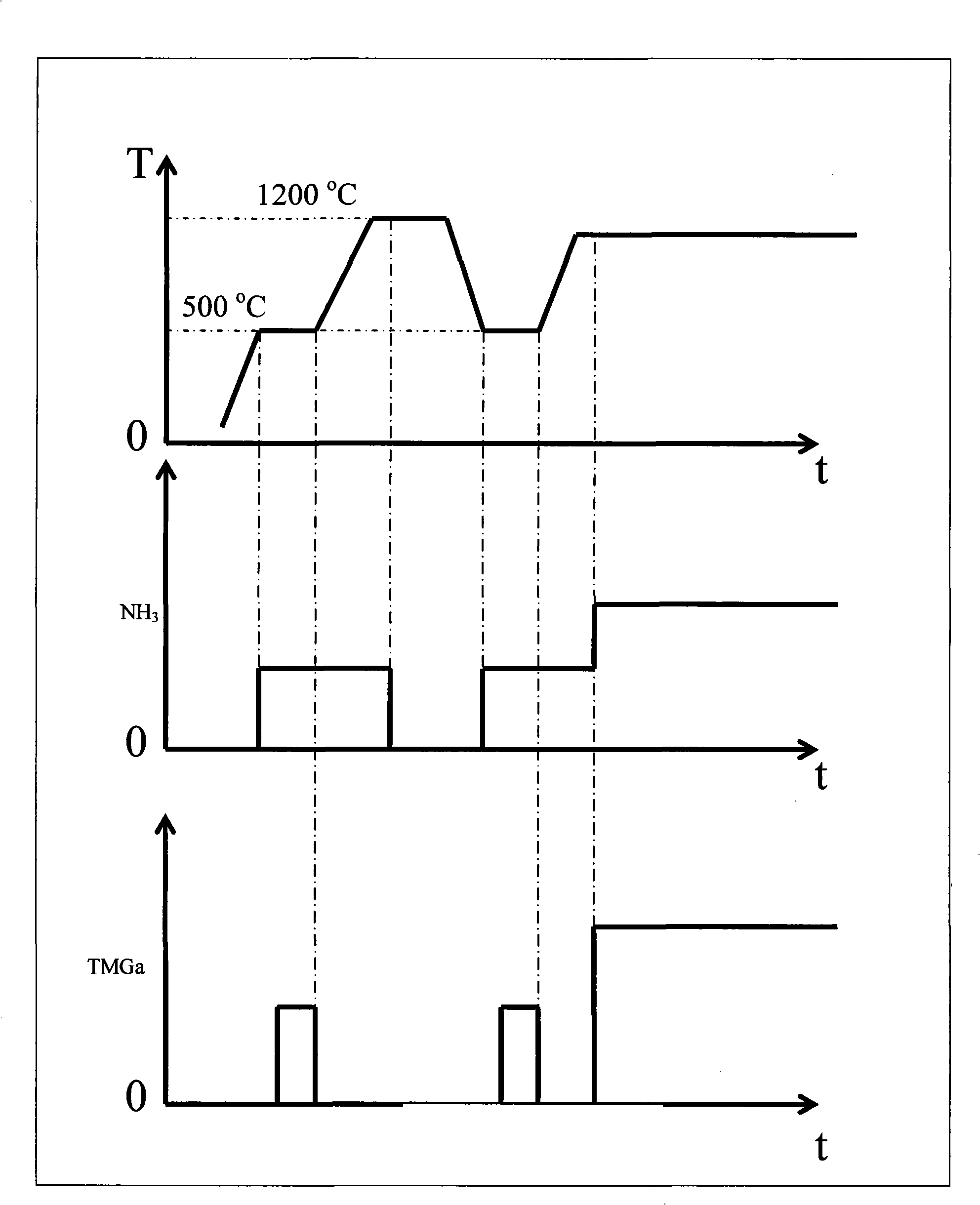

[0030] Further illustrate the specific implementation steps of the present invention below in conjunction with accompanying drawing:

[0031] A method for growing a nitride epitaxial layer with MOVCD, which adopts MOCVD technology, uses high-purity NH3 as N source, high-purity H2 or N2 as carrier gas, trimethylgallium (TMGa) or triethylgallium (TEGa) and three Indium methyl (TMIn) and trimethylaluminum (TMAl) do Ga source and In source and Al source respectively; Substrate is sapphire (Al2O3); The method comprises the following steps:

[0032] Step 1, in the MOCVD reaction chamber, the sapphire substrate is heated to a relatively low temperature, preferably between 500°C and 900°C, with H2 or N2 gas as the carrier gas, and trimethylgallium (TMGa) and NH3 grows a GaN layer on the surface of sapphire; its thickness is preferably controlled between 10 nm and 200 nm. This layer of GaN is called the sacrificial layer;

[0033]Step 2, after the growth of the GaN sacrificial layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com