Method for growing high-quality gallium nitride epitaxial film on basis of gallium nitride substrate

A gallium nitride substrate and epitaxial thin film technology, applied in the semiconductor field, can solve the problems affecting the practical progress of GaN-based materials, and achieve the effects of simple and easy method, short growth period and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

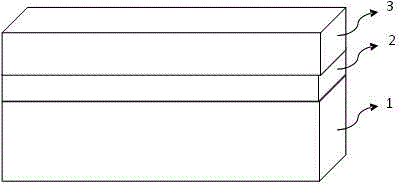

[0017] Such as figure 1 As shown, a method for growing a high-quality gallium nitride epitaxial film based on a gallium nitride substrate of the present invention is characterized in that it comprises the following steps:

[0018] 1) Select a substrate 1, which is a 0001-plane self-supporting gallium nitride substrate material;

[0019] 2) Put the substrate 1 into the metal organic chemical vapor deposition system, pass H 2 , the reaction chamber pressure is 100torr, and heated at 1050°C for 5min to clean the substrate surface and remove surface contamination;

[0020] 3) The temperature of the reaction chamber is lowered to 1000°C, and high-purity ammonia gas is introduced for nitriding, H 2 as a carrier gas. The reaction chamber pressure is 300torr, and the nitriding time is 3min;

[0021] 4) Reduce the temperature to 1020°C, reduce the pressure of the reaction chamber to 50torr, continue to pass in ammonia gas, and at the same time pass in trimethylgallium, and epitaxia...

Embodiment 2

[0024] Such as figure 1 As shown, a method for growing a high-quality gallium nitride epitaxial film based on a gallium nitride substrate of the present invention is characterized in that it comprises the following steps:

[0025] 1) Select a substrate 1, which is a 0001-plane self-supporting gallium nitride substrate material;

[0026] 2) Put the substrate 1 into the metal organic chemical vapor deposition system, pass H 2 , the reaction chamber pressure is 200torr, and heated at 1100°C for 3min to clean the substrate surface and remove surface contamination;

[0027] 3) The temperature of the reaction chamber is lowered to 1050°C, and high-purity ammonia gas is introduced for nitriding, H 2 as a carrier gas. The reaction chamber pressure is 500torr, and the nitriding time is 1min;

[0028] 4) Reduce the temperature to 980°C, reduce the pressure of the reaction chamber to 100torr, continue to pass in ammonia gas, and at the same time pass in trimethylgallium, and epitaxia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dislocation density | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com