Method for preparing ZnO transparent conductive film through metal organic chemical vapor deposition

A technology of transparent conductive film and coating chamber, which is used in gaseous chemical plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

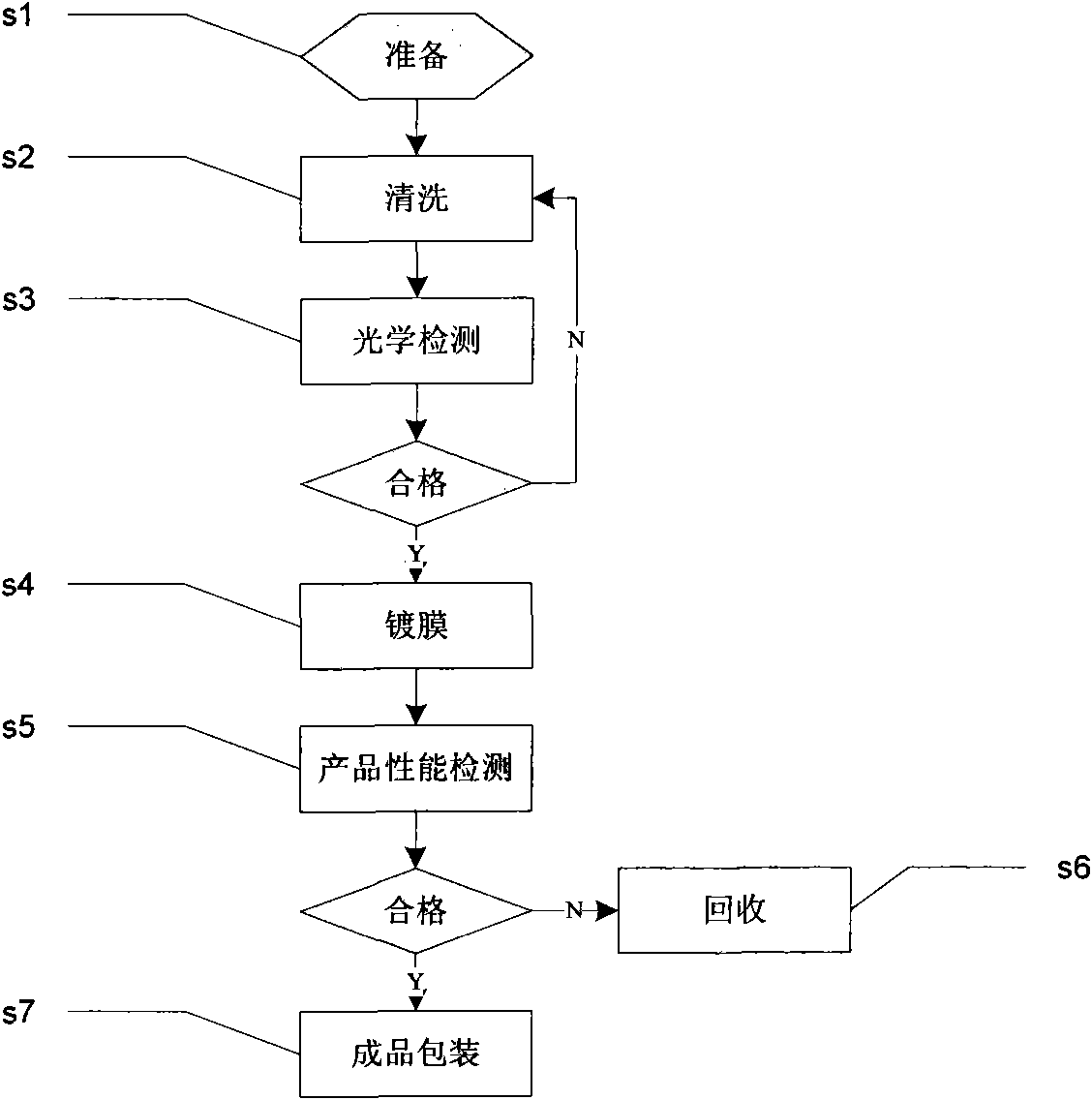

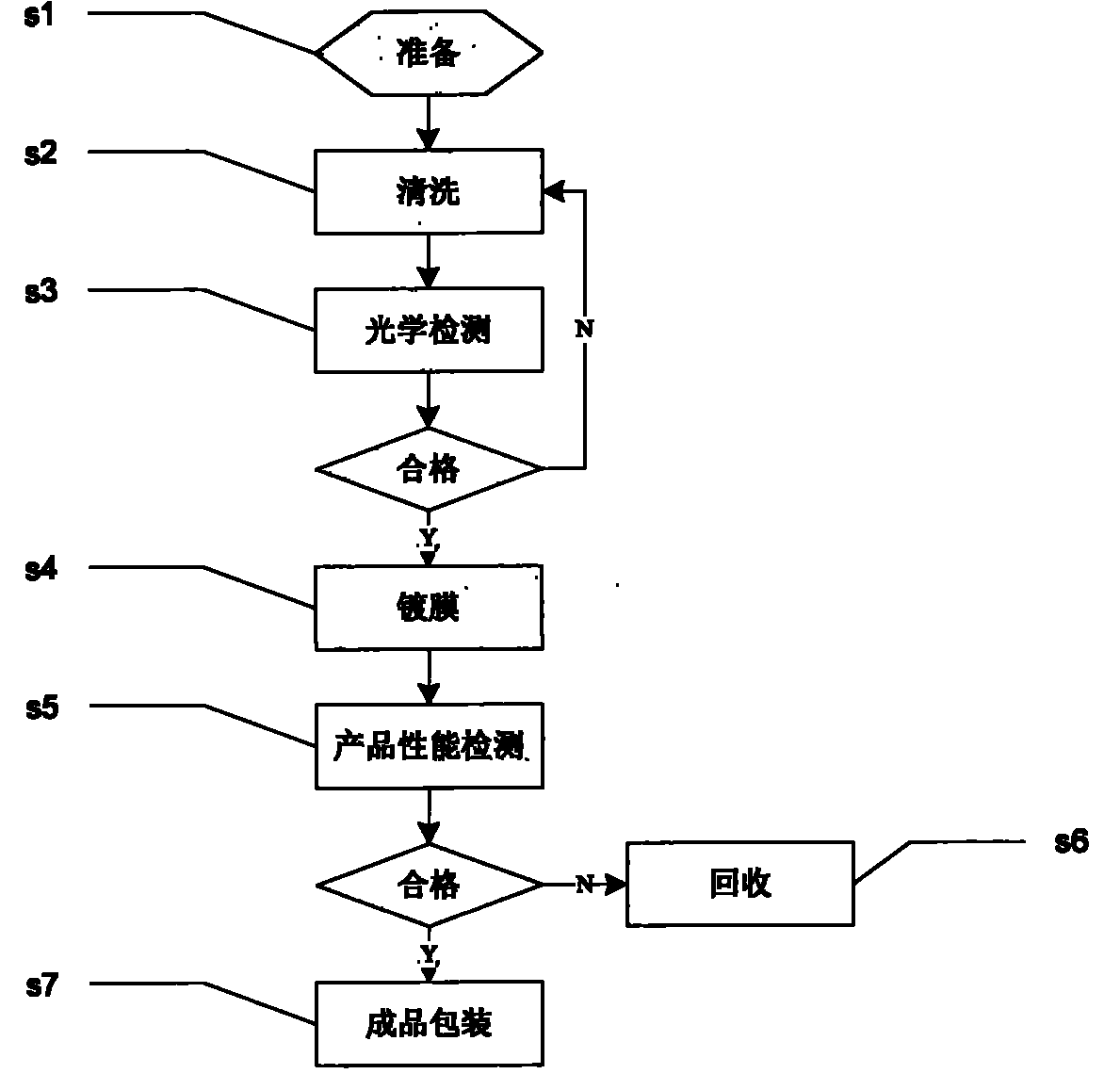

[0027] Such as figure 1 As shown, the MOCVD process of the present invention for preparing a ZnO transparent conductive film is as follows:

[0028] 1. Preparation (s1): The glass sheet equipment is online;

[0029] 2. Cleaning (s2): The glass sheet is transferred to the glass cleaning system, cleaned by standard glass cleaning process, and dried;

[0030] 3. Optical inspection (s3): The cleaned glass sheet is sent to the online optical inspection system for inspection; it mainly inspects whether there are residual stains on the glass surface;

[0031] 4. The unqualified glass is returned to the cleaning system for cleaning;

[0032] 5. Coating (s4): The inspected glass is sent to the CVD coating room for coating, and the dimethyl zinc and oxygen are used as sources and sprayed on the heated glass through the nozzle. The dimethyl zinc is oxidized to produce ZnO; trimethyl gallium or Alumina is the doping source, Ga-doped ZnO (GZO) or aluminum-doped ZnO (AZO) can be obtained respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com