Exhaust gas recovery method and device for LED epitaxial wafer preparation process

A technology for LED epitaxial wafer and waste gas recovery, which is applied in the preparation/separation of ammonia, chemical instruments and methods, refrigeration and liquefaction, etc., can solve the problems of energy waste, low quality of ammonia water, etc., to avoid waste, and the process is simple and good. Environmentally friendly and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

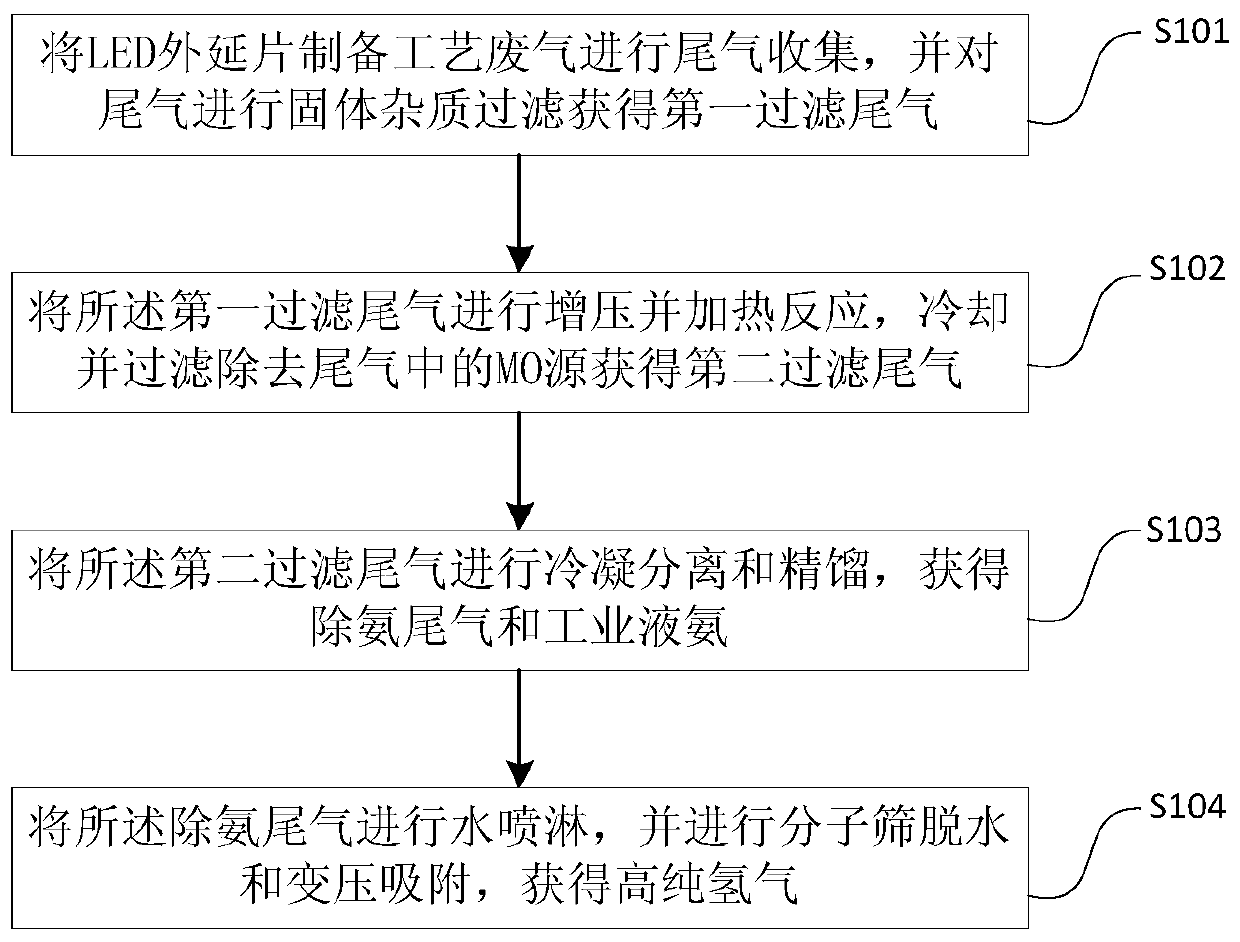

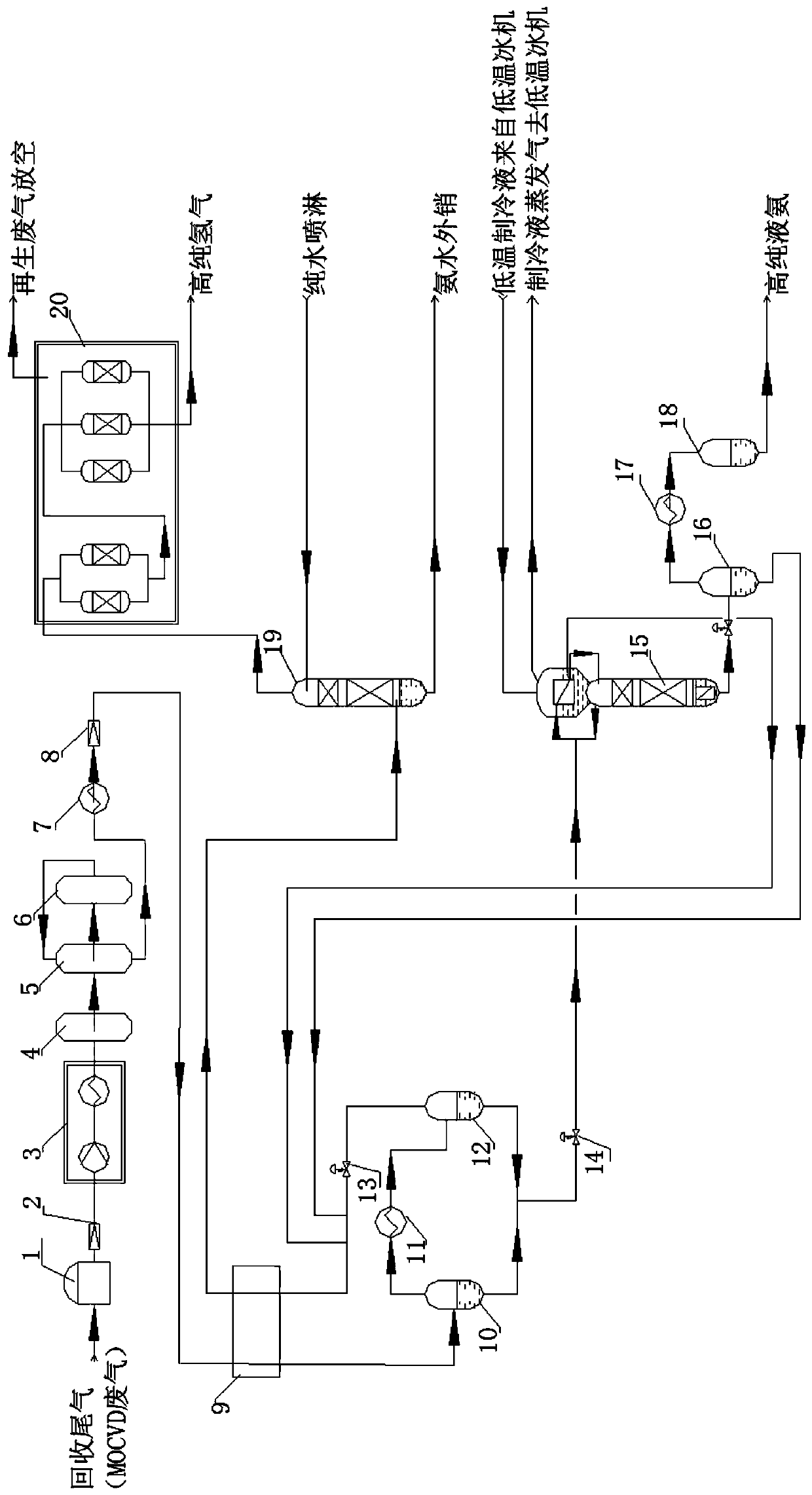

[0038] The exhaust gas discharged from the metal organic chemical vapor deposition process (MOCVD) in the LED epitaxial wafer production process is collected into the exhaust gas collection tank 1 through the exhaust gas collection pipeline, and the exhaust gas is passed into the dust filter 2 to remove particles in the exhaust gas Dust and other solid impurities obtain the first filtered exhaust gas to prevent particle dust from adversely affecting subsequent processing equipment.

[0039] Pass the first filtered exhaust gas into the exhaust compressor 3, pressurize the first filtered exhaust gas to 2.4Mpa, and heat the first filtered exhaust gas to a reaction temperature of 300°C through the heater 4, which can be an electric heater , can also be a combustion chamber, and then pass into the regenerator 5, the forward flow gas and the reacted counterflow gas exchange heat, recover heat energy, and then enter the reactor 6, under high temperature and high pressure conditions, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com