Method for preparing novel GaN-based laser and GaN-based laser

A laser, a new type of technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve epitaxial wafers that cannot be purchased from abroad for GaN-based lasers, GaN laser chips are difficult to prepare, development constraints, etc. problem, to achieve the effect of improving the light confinement effect, increasing the recombination efficiency, and increasing the confinement factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

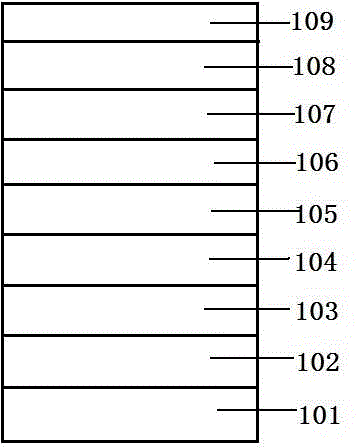

[0032] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. During the growth process, at least one of trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) was used as a group III source, ammonia gas (NH 3 ) as the Group V source, silane (SiH 4 ) as an n-type dopant source, magnesiumocene (Cp 2 Mg) as a p-type dopant source, firstly heat the GaN substrate 101 to 1050 degrees Celsius in the MOCVD reaction chamber, hydrogen (H 2 ) atmosphere, using TMGa as the III source, NH 3 As a Group V source, SiH 4 4 micron thick n-GaN 102 grown as an n-type dopant source with an electron concentration of 5×10 18 cm -3 ; in hydrogen (H 2 ) atmosphere, at 850 ° C ~ 1050 ° C, using TMGa, TMAl and TMIn as the group III source, NH 3 As a group V source, SiH4 is used as an n-type dopant source to grow 150 cycles of modulation-doped Al composition and n-Al with In composition and asymmetric structure 0.15 Ga 0.85 N / GaN / Al 0.15 In 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com