Gradient AlGaN layer preparation method and device prepared by same

A technology of buffer layer and epitaxy, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of inability to effectively adjust the stress and dislocation density of GaN thin films, slow growth rate, and affecting the quality of GaN thin film crystals, etc. problem, to achieve the effect of controllable distribution and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for preparing a graded AlGaN layer according to an embodiment of the present invention includes the following steps:

[0036] S1. growing a layer of high-temperature AlN layer 2 on the Si substrate 1 as a buffer layer;

[0037] S2. Growing a graded AlGaN layer 3 on the high-temperature AlN layer 2 .

[0038]After the graded AlGaN layer is prepared, the GaN thin film 4 and other required material layers can be grown sequentially on the graded AlGaN layer 3 to obtain the desired device.

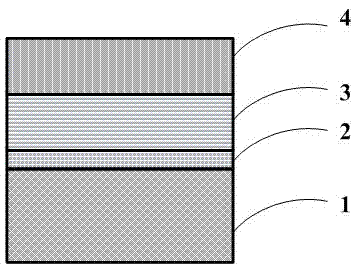

[0039] Such as figure 1 As shown, it is a schematic diagram of the device structure obtained by epitaxially growing a GaN thin film on the graded AlGaN layer obtained by the above method, including a Si substrate 1, a high-temperature AlN layer 2, a graded AlGaN layer 3 and a GaN thin film 4 from bottom to top.

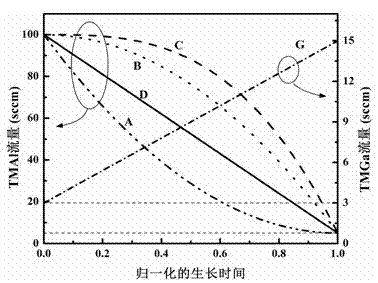

[0040] Wherein, the thickness of the graded AlGaN layer 3 is 1 μm, the growth temperature is 990° C., the growth pressure is 100 mbar, and the V / III ratio is 2000. ...

Embodiment 2

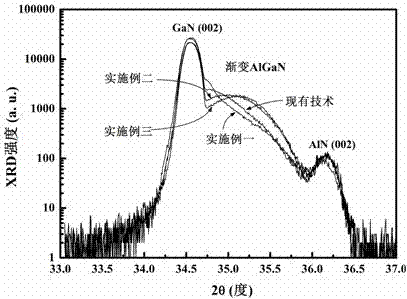

[0045] This embodiment is similar to Embodiment 1, the only difference being that the functions of the TMAl and TMGa flow rates are different from those of Embodiment 1, specifically: during the growth of the graded AlGaN layer, the TMAl flow rate drops from 100 sccm to 5 sccm, and its function is B= 100-95 x 2 (sccm), TMGa flow increases linearly from 3 sccm to 15 sccm, and its function curve is G=12 x +3 (sccm). in the above function x (0≤ x ≤1) is the normalized time for the growth of the graded AlGaN layer. Function curve such as figure 2 shown.

Embodiment 3

[0047] This embodiment is similar to Embodiment 1, the only difference being that the function of the flow of TMAl and TMGa is different from that of Embodiment 1, specifically: the flow of TMAl in the graded AlGaN layer drops from 100 sccm to 5 sccm, and its function is C=100- 95 x 3 (sccm), TMGa flow increases linearly from 3 sccm to 15 sccm, and its function curve is G=12 x +3 (sccm). In the above two functions x (0≤ x ≤1) is the normalized time for the growth of the graded AlGaN layer. Function curve such as figure 2 shown.

[0048] In order to better illustrate the effectiveness of a method for preparing a graded AlGaN layer of the present invention, the linear function in the prior art is used as a comparison, which is basically similar to that in the examples, except that the function of the TMAl and TMGa flow rates is the same as Different from Example 1, a linear function is adopted, specifically: during the growth process of the gradient AlGaN layer, the TM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com