A kind of preparation method of gallium oxide epitaxial film and gallium oxide epitaxial film

A gallium oxide and epitaxial film technology, applied in the field of semiconductor material preparation, can solve the problems of carbon and organic compound pollution, and achieve the effect of avoiding pollution and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

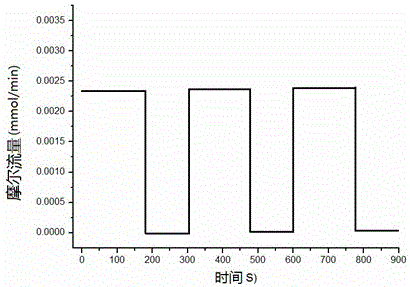

[0060] The MOCVD system used in the preparation method of a gallium oxide epitaxial film in the present invention refers to figure 1 , the MOCVD system includes: a source supply unit, a gas transport unit, a mass flow control unit, a reaction chamber 1, and a tail gas treatment unit; the source supply unit reaches the reaction chamber 1 through the gas transport unit under the control of the mass flow control unit , the reacted gas enters the tail gas treatment unit; the reaction chamber 1 is provided with a rotatable tray 2, and the reaction chamber is respectively connected with the mechanical pump 3 and the molecular pump 4 through pipelines.

[0061] This embodiment specifically includes the following steps:

[0062] Step 1: Select the single-crystal gallium oxide with (400) crystal plane as the substrate, and clean it for later use.

[0063] Step 2: Operate the MOCVD equipment, send the substrate into the sample pretreatment chamber, and use the mechanical pump 3 to roug...

Embodiment 2

[0074] The invention provides a method for preparing a gallium oxide epitaxial film, which specifically comprises the following steps:

[0075] Step 1: The substrate is a single crystal sapphire with (0006) crystal plane, cleaned and ready for use.

[0076] Step 2: Operate the MOCVD equipment, send the substrate into the sample pretreatment chamber, and use the mechanical pump 3 to roughly evacuate the reaction chamber 1 .

[0077] Step 3: Start the turbomolecular pump 4 when the vacuum degree of the reaction chamber 1 reaches 2 Pa, and pump the vacuum degree of the back of the reaction chamber 1 to 4×10 -4 Below Pa, the substrate is then sent from the pretreatment chamber into the reaction chamber 1, and the tray 2 on which the substrate is placed is started to be heated. After the temperature is raised to 750° C., the substrate is heat-treated for 30 minutes.

[0078] Step 4: After the pretreatment is completed, lower the temperature of the tray 2 to the growth temperature ...

Embodiment 3

[0087] The invention provides a method for preparing a gallium oxide epitaxial film, which specifically comprises the following steps:

[0088] Step 1: The substrate is a single crystal sapphire with (0006) crystal plane, cleaned and ready for use.

[0089] Step 2: Operate the MOCVD equipment, send the substrate into the sample pretreatment chamber, and use the mechanical pump 3 to roughly evacuate the reaction chamber 1 .

[0090] Step 3: Start the turbomolecular pump 4 when the vacuum degree of the reaction chamber 1 reaches 3Pa, and pump the vacuum degree of the back of the reaction chamber 1 to 5×10 -4 Below Pa, the substrate is then sent from the pretreatment chamber into the reaction chamber 1, and the tray 2 on which the substrate is placed is started to be heated. After the temperature is raised to 1100°C, the substrate is heat-treated for 20 minutes.

[0091] Step 4: After the pretreatment is completed, lower the temperature of the tray 2 to the growth temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com