Method for preparing high-purity trimethylgallium at one step

A high-purity technology of trimethylgallium, which is applied in the field of one-step preparation of high-purity trimethylgallium, can solve problems affecting the purity of substances, and achieve the effects of convenient purification, cost saving, and increased boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

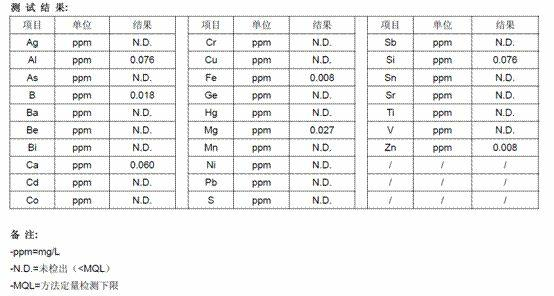

Examples

Embodiment 1

[0024] 500g gallium-magnesium alloy Ga x Mg y and metallic magnesium Mg z Put it into the reaction kettle and protect it with inert gas. Wherein x=0.2, y=0.4, z=0.4, x+y+z=1, wherein x, y, z are molar ratios. Add 1200g of tetraethylene glycol dimethyl ether, and gradually add 1950g of methyl iodide dropwise under the condition of normal temperature stirring. After the reaction is completed, continue to reflux at a temperature of 60-100°C for 6h, distill off low boiling point substances, and then continue to raise the temperature to decompose The compounding temperature was controlled at 160-220°C to obtain 239g of high-purity trimethylgallium with a yield of 69% (calculated based on the mass of gallium metal).

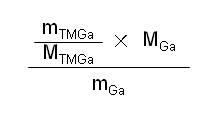

[0025] The yield is calculated as follows:

[0026]

[0027] in:

[0028] m TMGa In order to obtain the quality of high-purity trimethylgallium,

[0029] m TMGa is the molecular weight of trimethylgallium,

[0030] m Ga is the molecular weight of gallium, ...

Embodiment 2

[0033] 500g gallium-magnesium alloy Ga x Mg y and metallic magnesium Mg z Put it into the reaction kettle and protect it with inert gas. Wherein x=0.25, y=0.5, z=0.25, x+y+z=1, wherein x, y, z are molar ratios. Add 1200g of tetraethylene glycol dimethyl ether, and gradually add 1950g of methyl iodide dropwise under the condition of normal temperature stirring. After the reaction is completed, continue to reflux at a temperature of 60-100°C for 6h, distill off low boiling point substances, and then continue to raise the temperature to decompose The mixing temperature was controlled at 160-220°C to obtain 324g of high-purity trimethylgallium with a yield of 80% (calculated based on the mass of gallium metal).

Embodiment 3

[0035] 500g gallium-magnesium alloy Ga x Mg y and metallic magnesium Mg z Put it into the reaction kettle and protect it with inert gas. Wherein x=0.3, y=0.4, z=0.3, x+y+z=1, wherein x, y, z are molar ratios. Add 1200g of tetraethylene glycol dimethyl ether, and gradually add 1950g of methyl iodide dropwise under the condition of normal temperature stirring. After the reaction is completed, continue to reflux at a temperature of 60-100°C for 6h, distill off low boiling point substances, and then continue to raise the temperature to decompose The compounding temperature was controlled at 160-220°C to obtain 333g of high-purity trimethylgallium with a yield of 73% (calculated based on the mass of gallium metal).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com