Light-emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems that the uniform current diffusion does not have an ideal effect, other properties of the material are reduced, and the uniform current diffusion does not play an obvious effect. , to achieve the effect of improving compliance efficiency, improving the ability to resist static electricity, and improving luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the light emitting diode is provided with a first insertion layer inside the n-type semiconductor layer, and a second insertion layer is provided between the n-type semiconductor layer and the active layer.

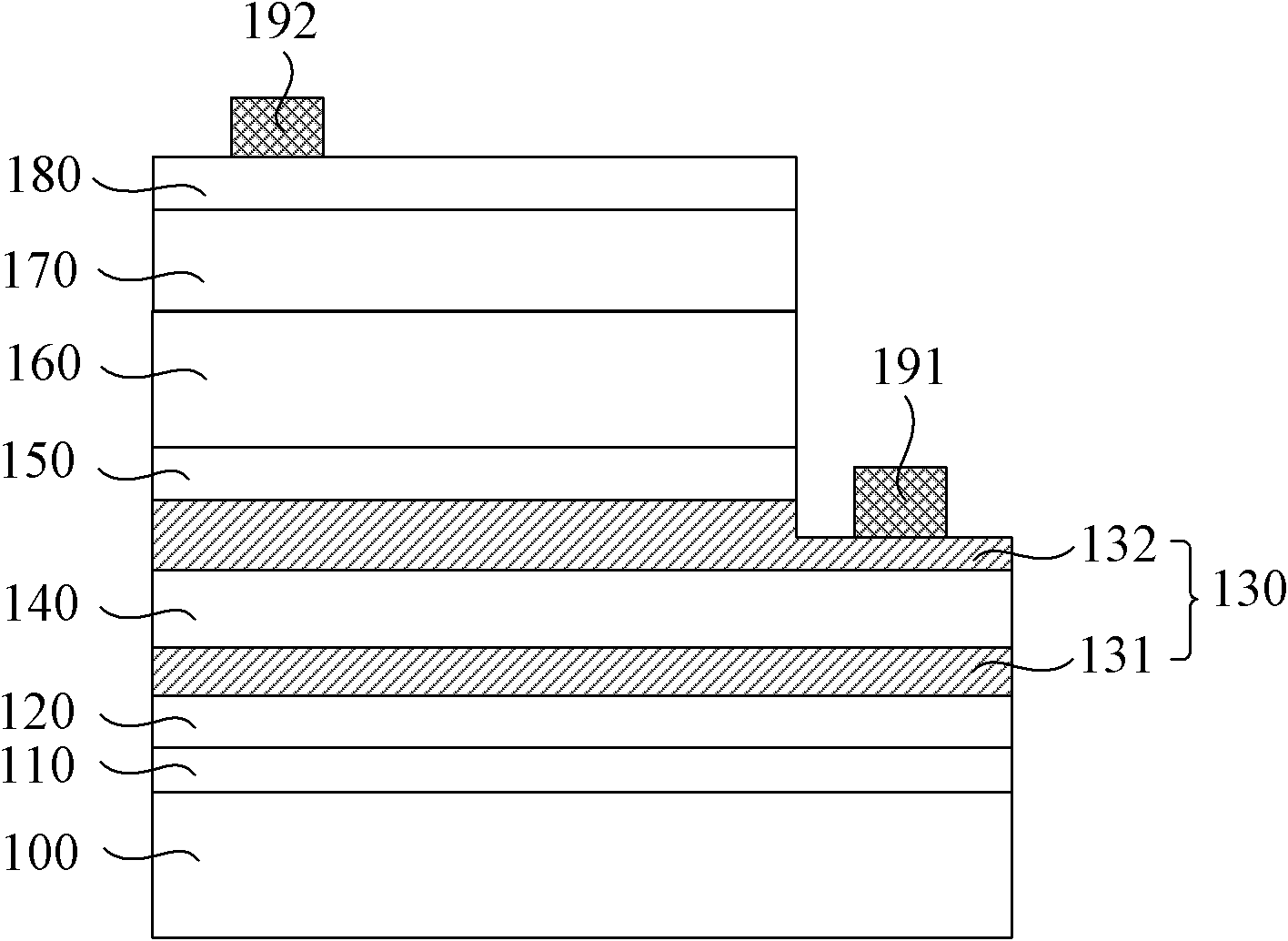

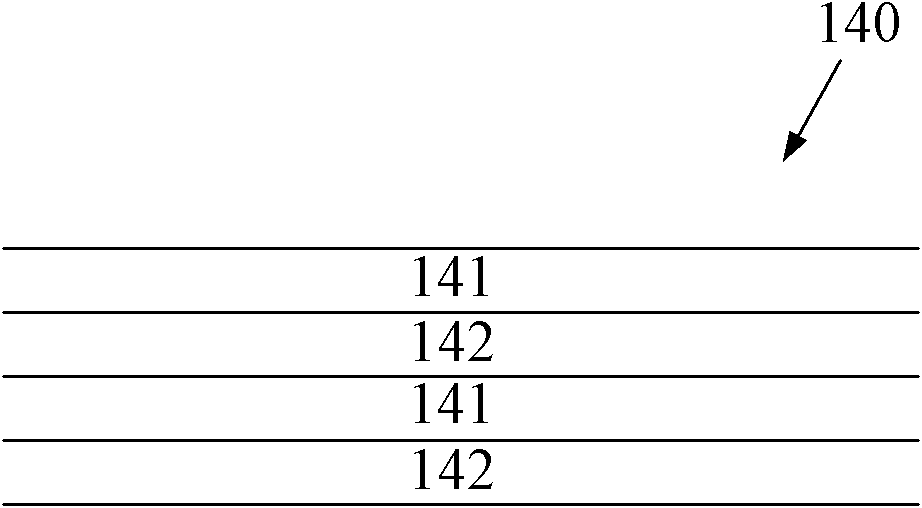

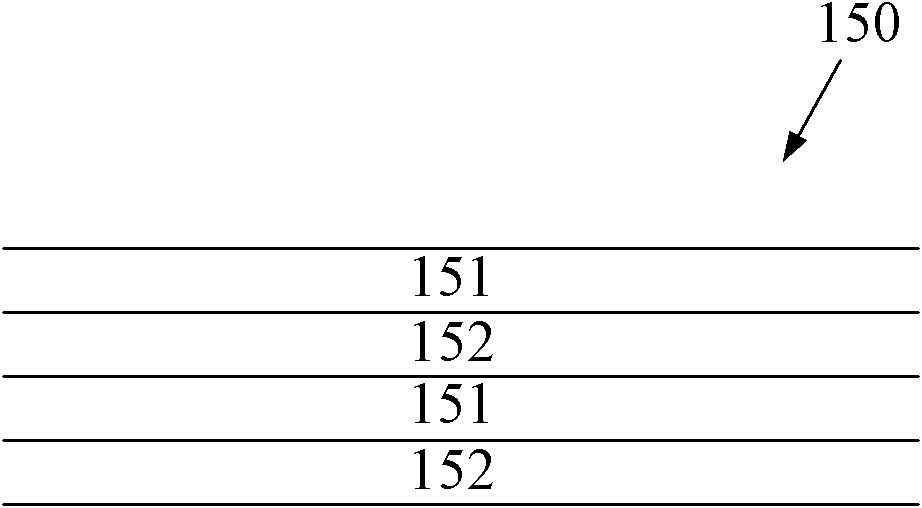

[0027] Please refer to figure 1 , Figure 2A and Figure 2B ,in, figure 1It is a schematic structural diagram of a light emitting diode according to Embodiment 1 of the present invention, Figure 2A for figure 1 A schematic diagram of the first insertion layer of the LED shown, Figure 2B for figure 1 Schematic of the second insertion layer of the LED shown.

[0028] Such as figure 1 As shown, taking a gallium nitride-based blue light diode as an example, the light emitting diode includes: a substrate 100; a buffer layer 110, an undoped layer 120, an n-type semiconductor layer 130, an active Layer 160, p-type semiconductor layer 170, and current spreading layer 180; in addition, the light emitting diode also includes a first insertion la...

Embodiment 2

[0043] The difference between this embodiment and the first embodiment is that the light emitting diode only has a first insertion layer inside the n-type semiconductor layer.

[0044] For details, please refer to image 3 , which is a schematic structural diagram of a light emitting diode according to Embodiment 2 of the present invention. The light emitting diode comprises: a substrate 200; a buffer layer 210, an undoped layer 220, an n-type semiconductor layer 230, an active layer 260, a p-type semiconductor layer 270, and a current diffusion layer 280 sequentially located on the substrate 200; In addition, the light emitting diode further includes a first insertion layer 240 disposed inside the n-type semiconductor layer 230, wherein the first insertion layer 240 is made of at least one layer of non-doped Al x In y Ga 1-x-y N layer and / or at least one layer of Si-doped Al x In y Ga 1-x-y Consists of N layers, where 0≤x<0.2, 0≤y<0.2. When current is injected into the...

Embodiment 3

[0047] The difference between this embodiment and the first embodiment is that the light emitting diode only has a second insertion layer between the n-type semiconductor layer and the active layer.

[0048] The light-emitting diode includes: a substrate; a buffer layer, a non-doped layer, an n-type semiconductor layer, an active layer, a p-type semiconductor layer, and a current diffusion layer sequentially located on the substrate; in addition, the light-emitting diode also includes A second insertion layer disposed between the n-type semiconductor layer and the active layer, the second insertion layer is composed of at least one layer of non-doped Al x In y Ga 1-x-y N layer and / or at least one layer of Si-doped Al x In y Ga 1-x-y N layers, where 0≤x<0.2, 0≤y<0.2. When current is injected into the n-type region, the second insertion layer can act as a buffer, preventing electrons from diffusing to the p-type region, improving the coincidence efficiency of electrons and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com