LED structure and growth method thereof

A technology of LED structure and growth method, which is applied in the field of optoelectronics, can solve the problems such as the inability to reduce the stress of the well layer, and achieve the effects of increasing the rate of spontaneous emission and internal quantum efficiency, increasing the probability of overlapping, and reducing the degree of lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

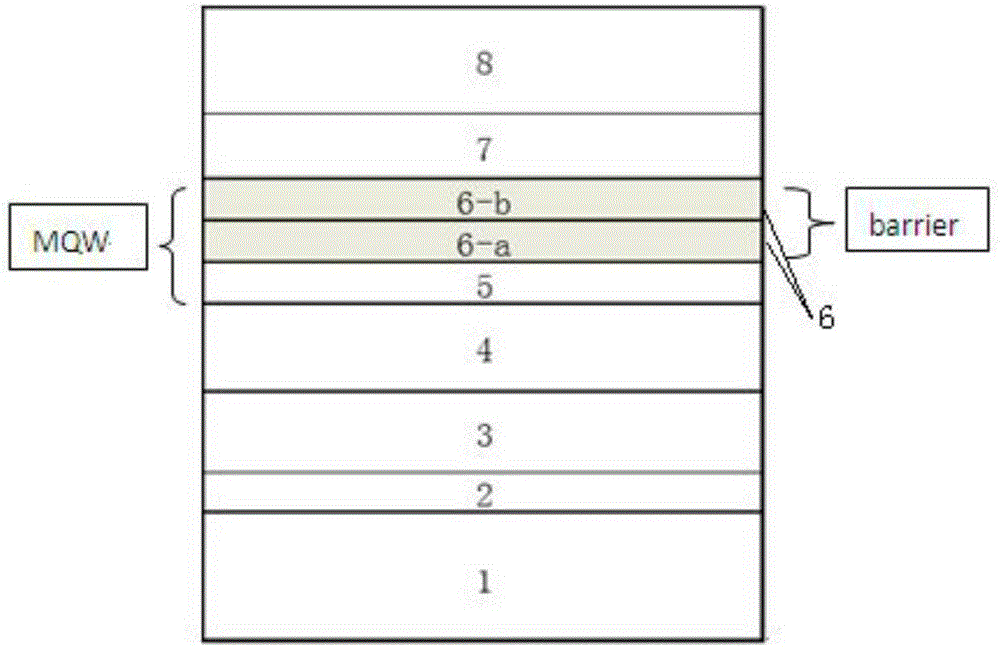

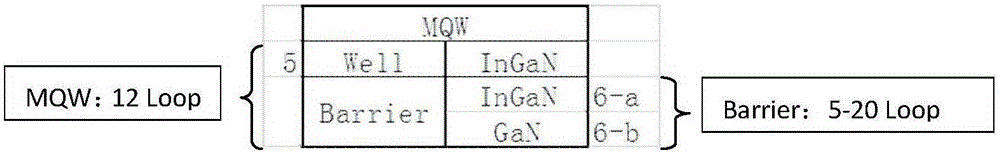

[0012] The technical scheme of the present invention is as follows:

[0013] An LED structure, comprising a substrate layer, a GaN buffer layer, an undoped GaN layer, a Si-doped GaN layer, a P-type AlGaN layer and a P-type GaN layer; it is characterized in that the Si-doped GaN layer and P-type AlGaN layers include multiple quantum well active regions of InGaN / GaN superlattice barrier layers.

[0014] Preferably, according to the present invention, the InGaN / GaN superlattice barrier layer includes InGaN barrier layers and GaN barrier layers that are grown alternately and periodically.

[0015] According to the present invention, preferably, the multiple quantum well active region includes InGaN well layers and InGaN / GaN superlattice barrier layers that are grown alternately and periodically.

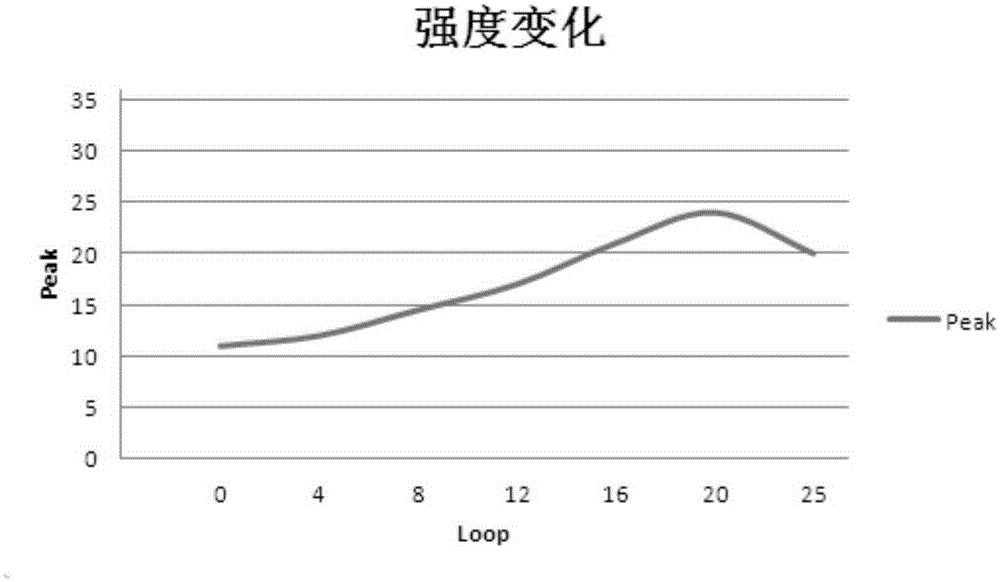

[0016] According to the present invention, preferably, the alternating period of the InGaN barrier layer and the GaN barrier layer in the InGaN / GaN superlattice barrier layer is 5-20 times.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com