Vertical-cavity surface-emitting laser and manufacturing method thereof

A vertical cavity surface emission and laser technology, which is used in lasers, laser parts, semiconductor lasers, etc., can solve problems such as performance degradation, difficulty in obtaining high-quality InGaAsN, etc., to improve yield and life, reduce threshold current, and avoid series connection. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below with reference to the accompanying drawings.

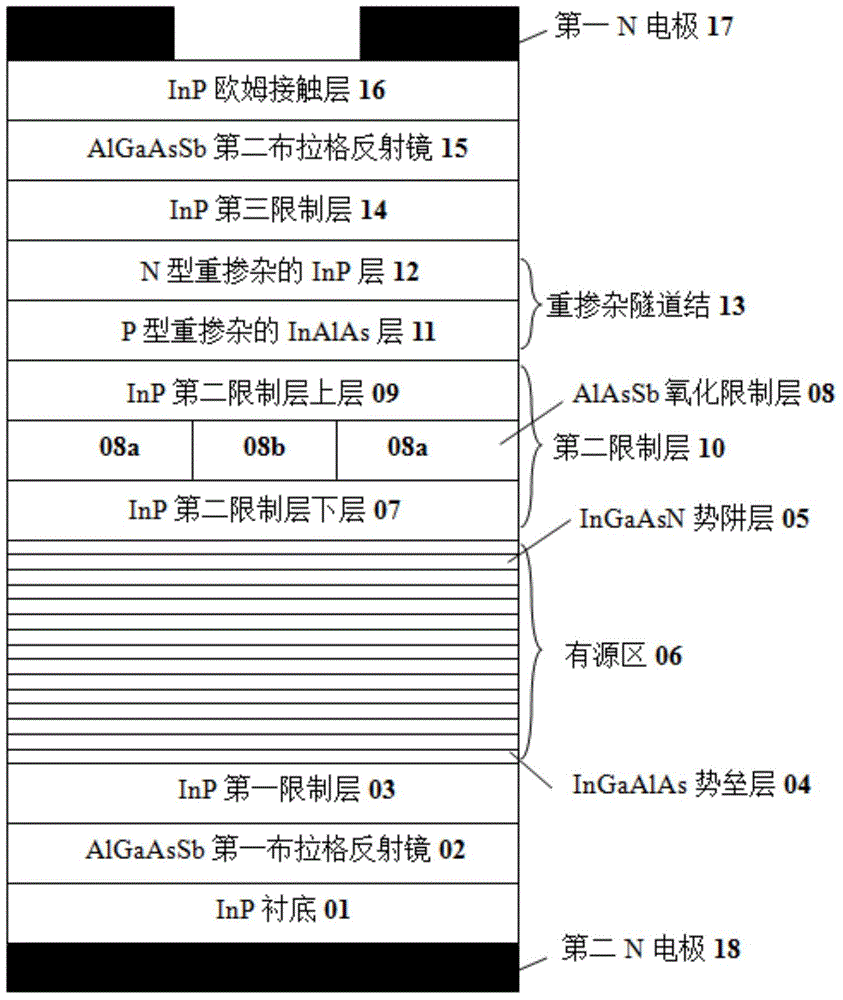

[0051] As mentioned above, in view of the deficiencies in the prior art, the present invention proposes a vertical cavity surface emitting laser, including an active region, wherein the active region is a quantum well structure, and the quantum well structure includes at least one A potential well layer and a plurality of potential barrier layers, the potential well layer is arranged between the potential barrier layers, wherein the material of the potential barrier layer is InGaAlAs, and the material of the potential well layer is InGaAsN. The vertical cavity surface emitting laser provided by the invention can effectively reduce the threshold current and increase the output power.

[0052] As a more preferred solution, in the present invention, the period number of the quantum well structure is K, and the range of K is 1-20.

[0053] As a more preferred solution, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com