Construction method of gob-side entry retaining wall of solid filling coal mining

A technology of solid filling and construction method, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc. It can solve the problems of filling impact on the working face, loss of coal resources, and difficult construction, so as to solve the problem of gas accumulation and reduce the amount of auxiliary transportation , The effect of saving excavation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

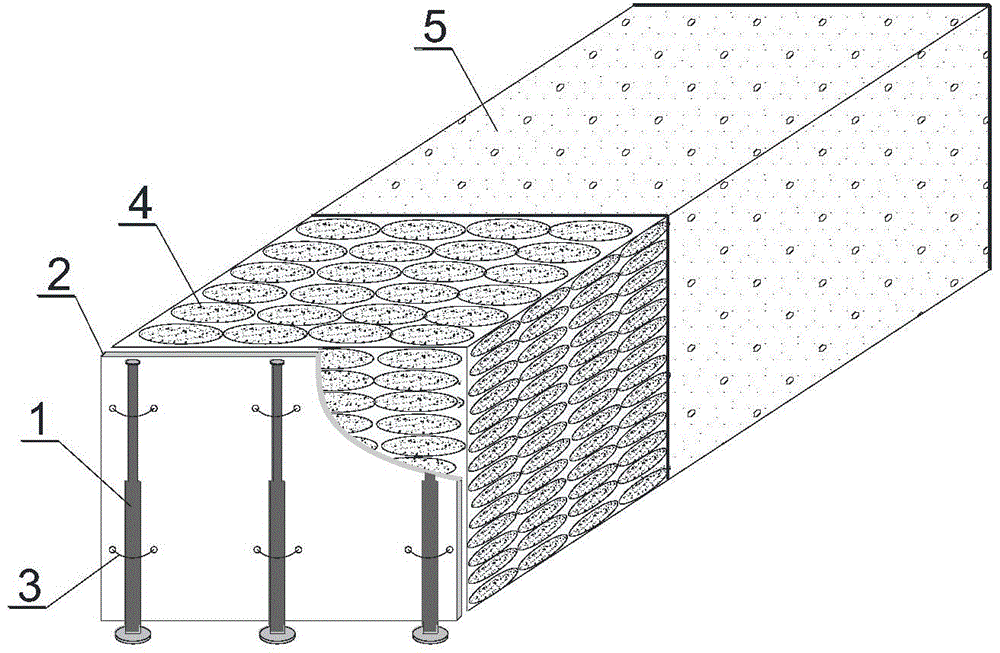

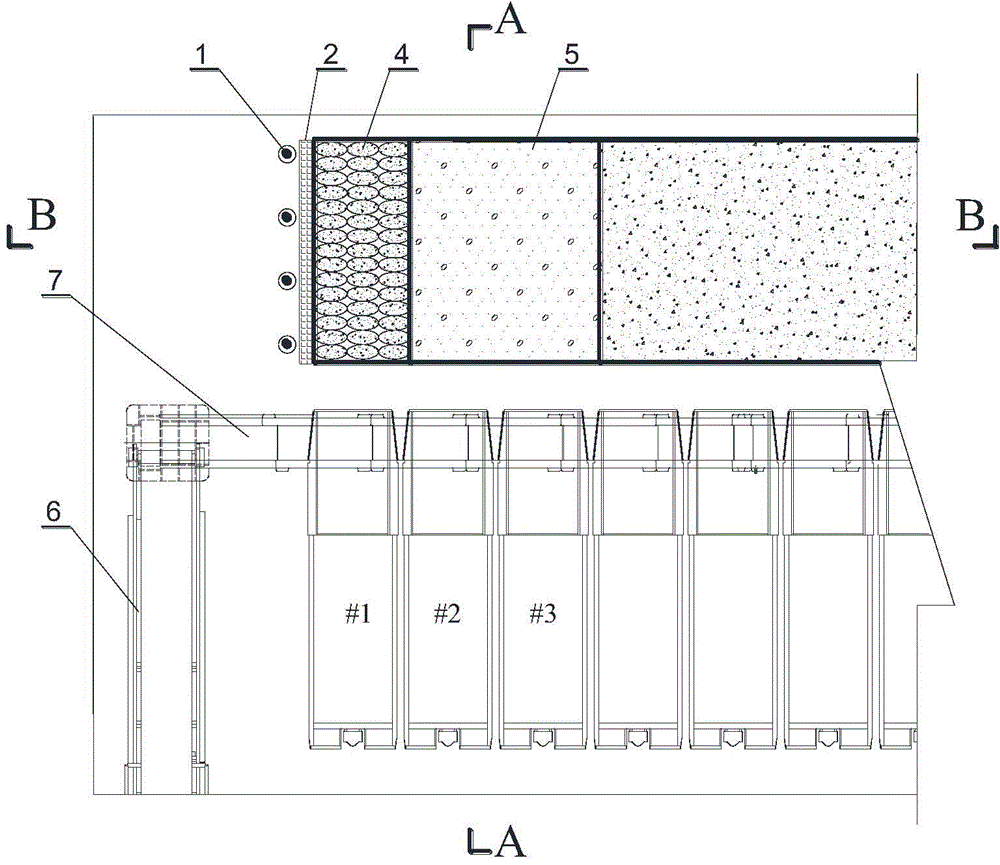

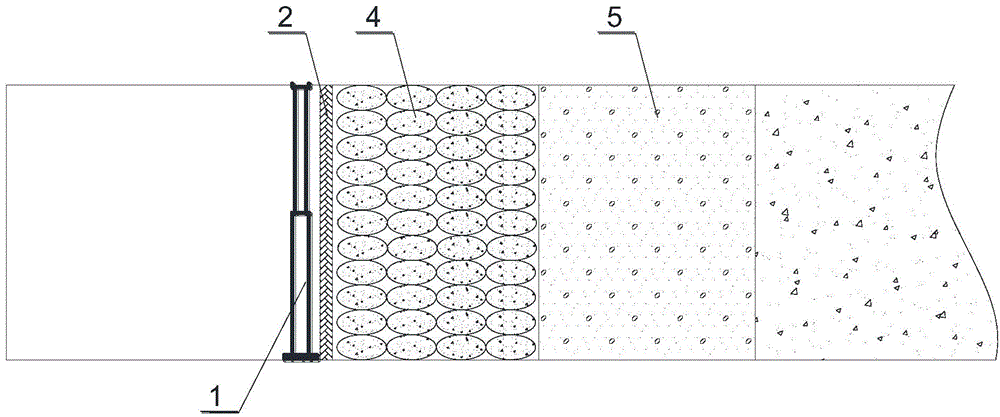

[0020] like Figure 1~4 As shown, the solid-filled coal mining gobside retaining support wall of the present invention is a mixed support body composed of a gangue wall 4 and a dense cemented filling body 5, and the gangue wall 4 is a common gangue wall filled with gangue. It is made of woven bags or snakeskin bags, and the densely cemented filling body 5 is formed by tamping the cement gangue mixture. The construction method of the solid filling gobside retaining roadway to support the wall, the specific steps are as follows:

[0021] a. After coal mining on the working face and removal of the frame, the floating coal near the end is cleaned, and then a row of single pillars 1 is built in the roadway near the goaf side, and the distance between the single pillars 1 is generally 0.6-1.0m;

[0022] b. Install a wooden backboard 2 close to the single pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com