TiO2-loaded graphene oxide sheet layer material and preparation method thereof

A graphene sheet, graphene technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unsatisfactory improvement and limitation of agglomeration, and achieve the effect of easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

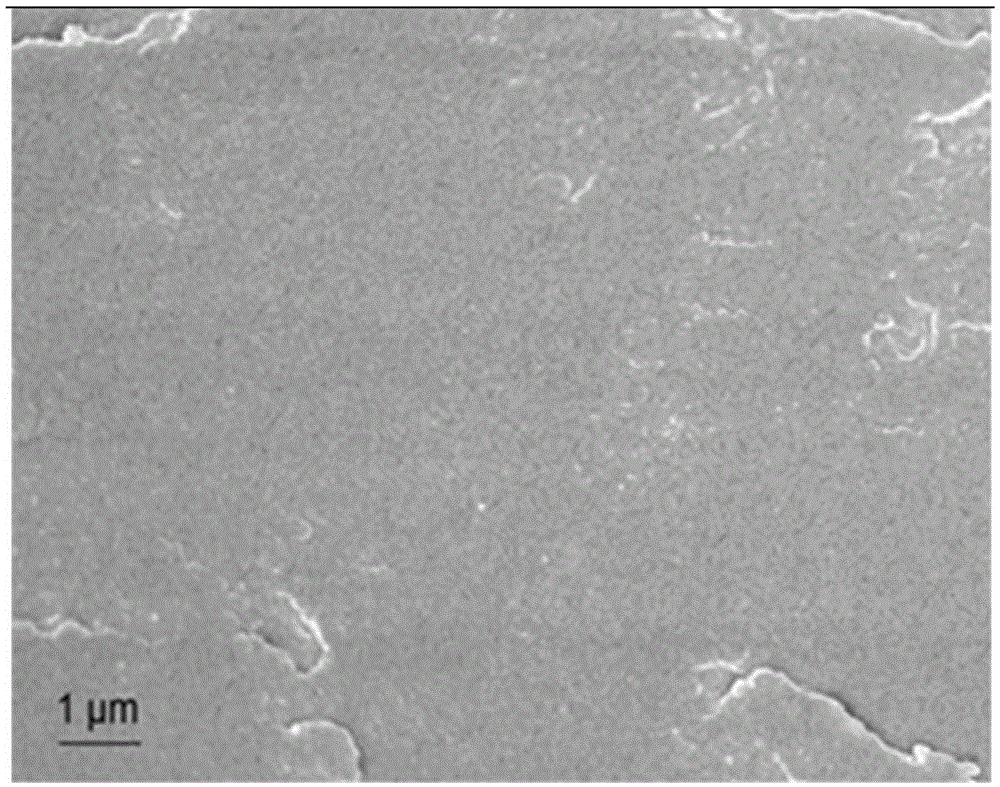

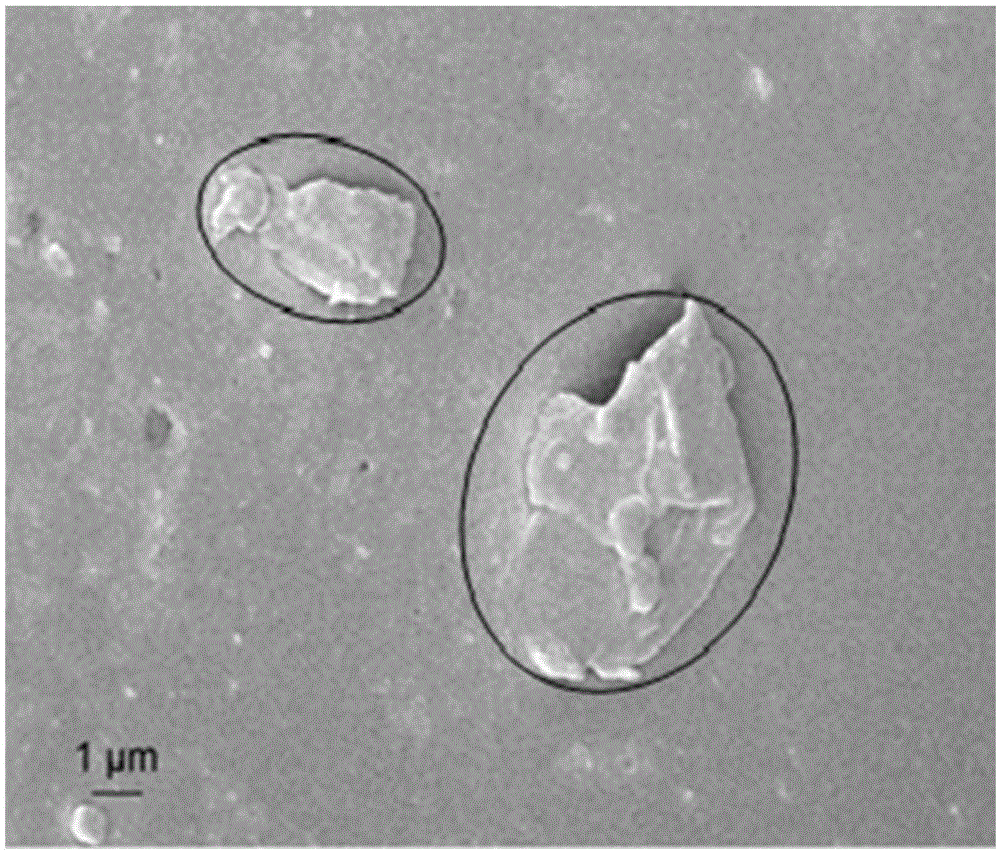

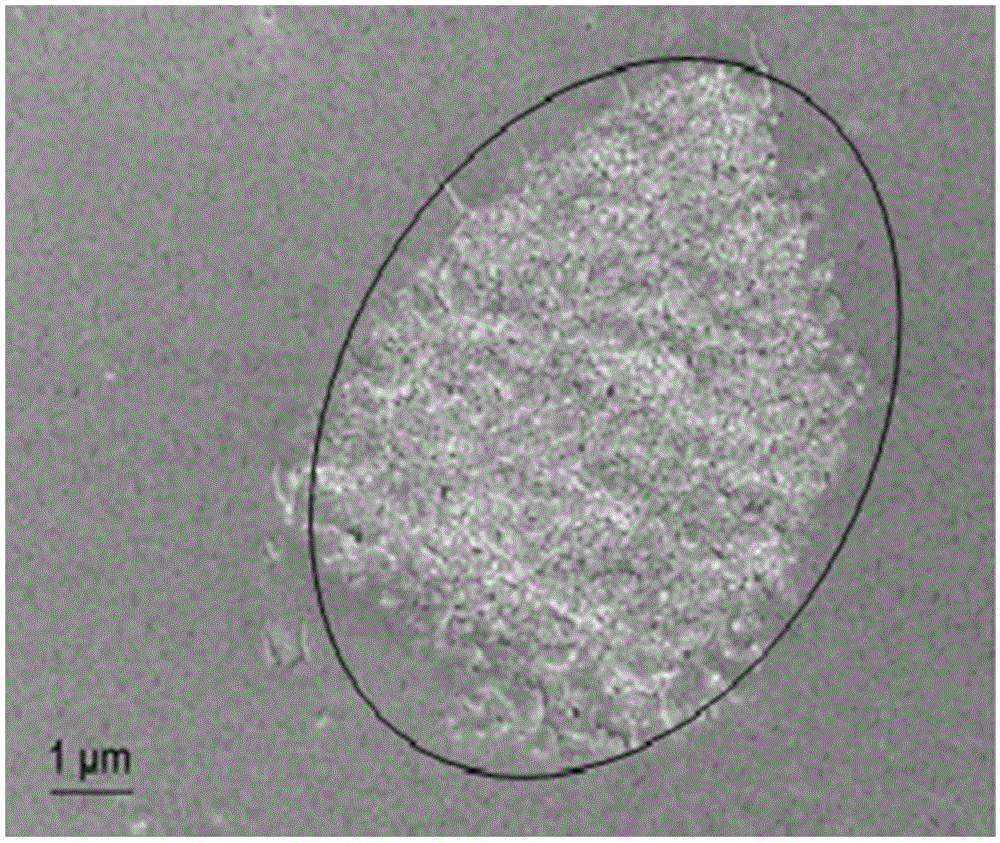

Image

Examples

Embodiment 1

[0025] A kind of TiO 2 The preparation method of loaded graphene oxide sheet material comprises the following steps:

[0026] (1) Preparation of graphene oxide (GO)

[0027] Mix 1g of natural graphite and 24mL of 98% concentrated sulfuric acid, stir in an ice-water bath for 30min, then add 1g of sodium nitrate, 5g of potassium permanganate, stir for 1.5h, raise the temperature to 39°C for 2h, then add 41mL of deionized water, 95°C Stir for 1 h, then add 120 mL of 10% hydrogen peroxide, react for 30 min, continue to add 5 mL of hydrochloric acid, centrifuge, wash the solid matter with deionized water and absolute ethanol for 5 times, and finally, dry the solid in a vacuum oven at 60°C for 24 h. Obtain graphene oxide;

[0028] (2) Modified TiO 2 (f-TiO 2 )preparation

[0029] Weigh 0.1g nano-TiO 2 Ultrasonic disperse 4g KH550 in 100g absolute ethanol for 30min, add 14g distilled water, stir and react at 78°C for 6h, centrifuge and filter, wash the solid matter repeatedly w...

Embodiment 2

[0033] A kind of TiO 2 The preparation method of loaded graphene oxide sheet material comprises the following steps:

[0034] (1) Preparation of graphene oxide (GO)

[0035] Mix 1g of natural graphite and 24mL of 98% concentrated sulfuric acid, stir in an ice-water bath for 30min, then add 1g of sodium nitrate, 5g of potassium permanganate, stir for 1.5h, raise the temperature to 39°C for 2h, then add 41mL of deionized water, 95°C Stir for 1 h, then add 120 mL of 10% hydrogen peroxide, react for 30 min, continue to add 5 mL of hydrochloric acid, centrifuge, wash the solid matter with deionized water and absolute ethanol for 5 times, and finally, dry the solid in a vacuum oven at 60°C for 24 h. Obtain graphene oxide;

[0036] (2) Modified TiO 2 (f-TiO 2 )preparation

[0037] Weigh 0.1g nano-TiO 2 Ultrasonic disperse 4g KH550 in 100g absolute ethanol for 30min, add 14g distilled water, stir and react at 78°C for 6h, centrifuge and filter, wash the solid matter repeatedly w...

Embodiment 3

[0041] A kind of TiO 2 The preparation method of loaded graphene oxide sheet material comprises the following steps:

[0042] (1) Preparation of graphene oxide (GO)

[0043] Mix 1g of natural graphite and 24mL of 98% concentrated sulfuric acid, stir in an ice-water bath for 30min, then add 1g of sodium nitrate, 5g of potassium permanganate, stir for 1.5h, raise the temperature to 39°C for 2h, then add 41mL of deionized water, 95°C Stir for 1 hour, then add 120 mL of 10% hydrogen peroxide, react for 30 minutes, continue to add 5 mL of hydrochloric acid, centrifuge, wash the solid matter with deionized water and absolute ethanol for 5 times, and finally, dry the solid in a vacuum oven at 60°C for 24 hours. Obtain graphene oxide;

[0044] (2) Modified TiO 2 (f-TiO 2 )preparation

[0045] Weigh 0.1g nano-TiO 2 Ultrasonic disperse 4g KH550 in 100g absolute ethanol for 30min, add 14g distilled water, stir and react at 78°C for 6h, centrifuge and filter, wash the solid matter r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com