Air blowing clamp for numerical control machine tool

A technology of CNC machine tools and fixtures, applied in the field of tooling and fixtures, can solve the problems of reducing production efficiency, easy deviation of dimensions, and product quality, etc., and achieves the effect of reducing defective rate, ensuring accuracy, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

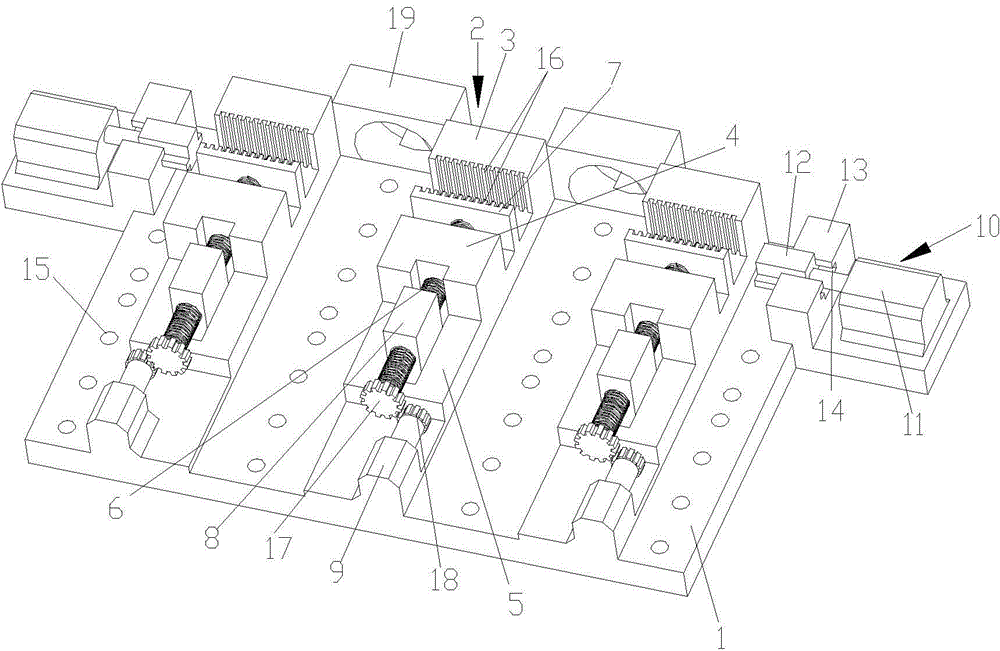

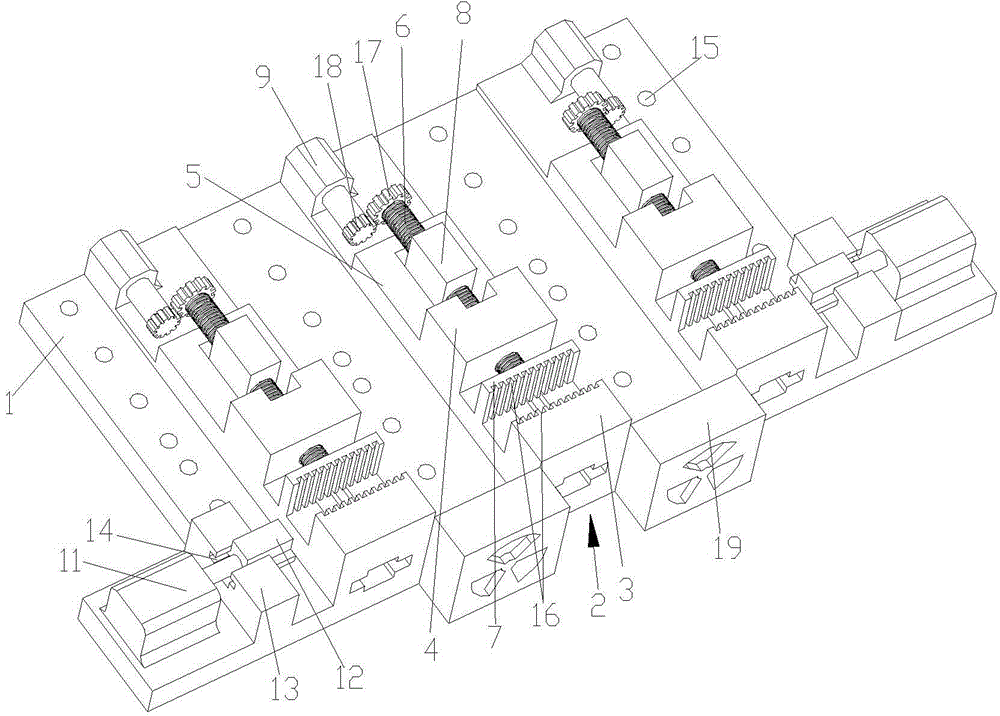

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached figure 1 , 2 Shown is a blowing fixture for a CNC machine tool according to the present invention, including a base 1 and a processing station 2; the processing station 2 includes a fixed baffle 3, a support seat 4 and a moving groove 5; the fixed baffle 3 and the support seat 4 are provided with a clamping block 7 connected by a screw 6; one end of the screw 6 passes through the support seat 4 and is installed in the moving seat 8, and the first gear 17 is connected to the end extending out of the moving seat 8; The first gear 17 meshes with the second gear 18 arranged on the motor 9 on the base 1, and rotates the screw rod 6 through the rotation of the motor 9; 5; the processing station 2 is provided with three groups in parallel on the base 1, and a blowing device 19 is arranged between two; the base 1 is also provided with a top tightening structure 10 outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com