Sintered rope saw string bead and production method thereof

A wire saw beading and metal technology, which is applied in the field of wire saws, can solve the problems of poor chip removal, low efficiency, and low service life of single-layer diamond wire saws, and achieve smooth chip removal, long life, and improved cutting efficiency of wire saws. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

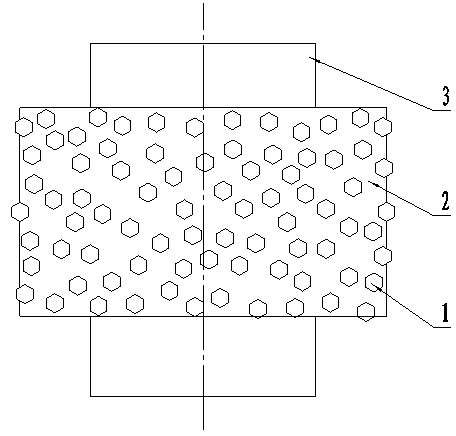

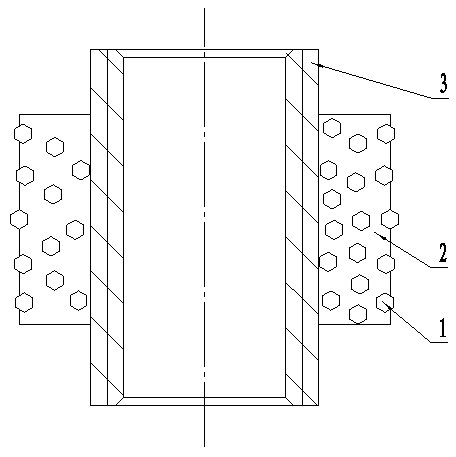

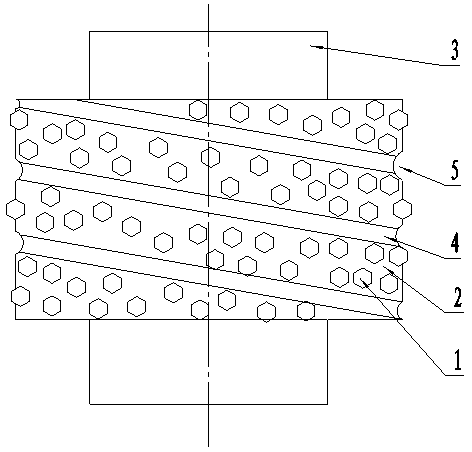

[0030] Example 1, GR115 type sintered wire saw beads, the height of the steel body 3 is 11mm, the outer diameter is 7.5mm, the height of the metal carcass 2 is 6mm, the outer diameter is 11.5mm, and the inner diameter is equal to the outer diameter of the steel body. The metal spacers do not contain diamonds in three circles, which are continuously distributed in the metal matrix 2 in a helical shape. The thickness of the metal spacer is 0.5 mm, the outer diameter of 11.44 mm is smaller than the outer diameter of the metal carcass 2 of 0.06 mm, and the inner diameter of 7.7 mm is larger than the outer diameter of the steel body 3 of 0.2 mm.

[0031] How it's made:

[0032] a. Choose hot-rolled copper square wire with a thickness of 0.5mm and a width of 1.87mm. Through a spring winding machine, it is wound into a spring-like spiral metal spacer, and the two ends are ground, and the outer diameter is the same as that of the metal tire. The outer diameter is equal, the number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com