Twist-drill oil-groove milling cutter

A twist drill and oil groove technology, which is applied in milling cutters, drill repairing, milling machine equipment, etc., can solve the problems of unstable cutting, inconvenient sharpening, small chip groove, etc., to save manufacturing costs, smooth chip removal, and stable cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

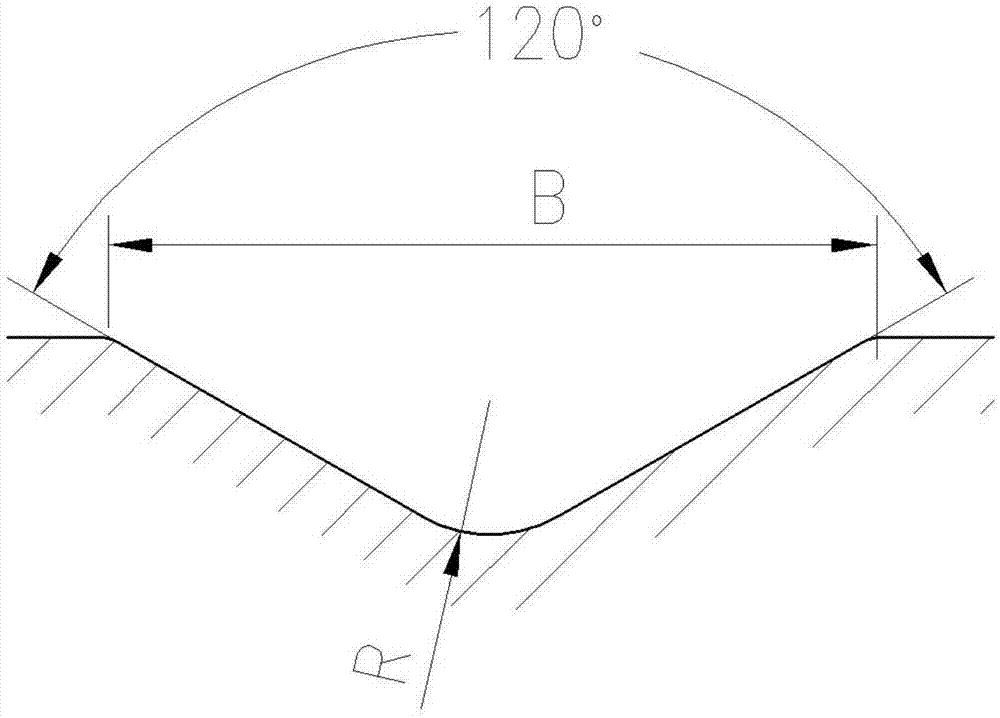

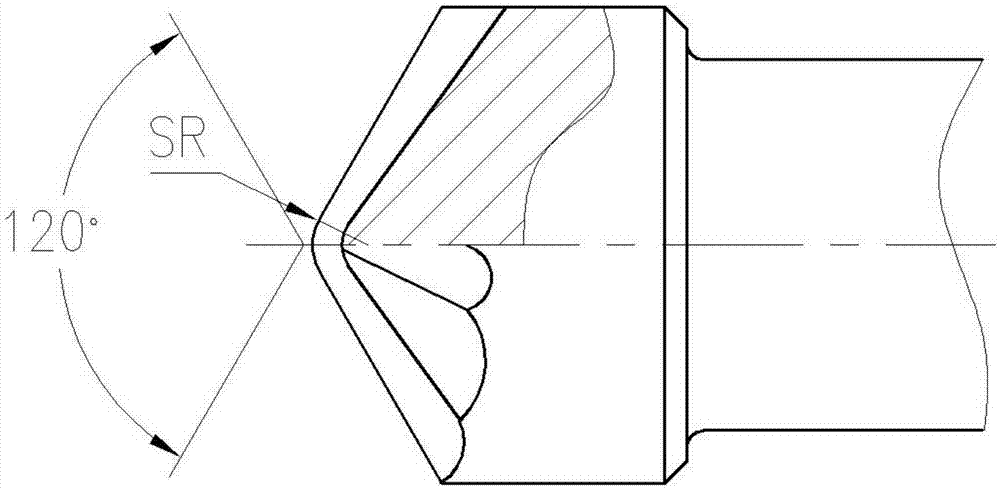

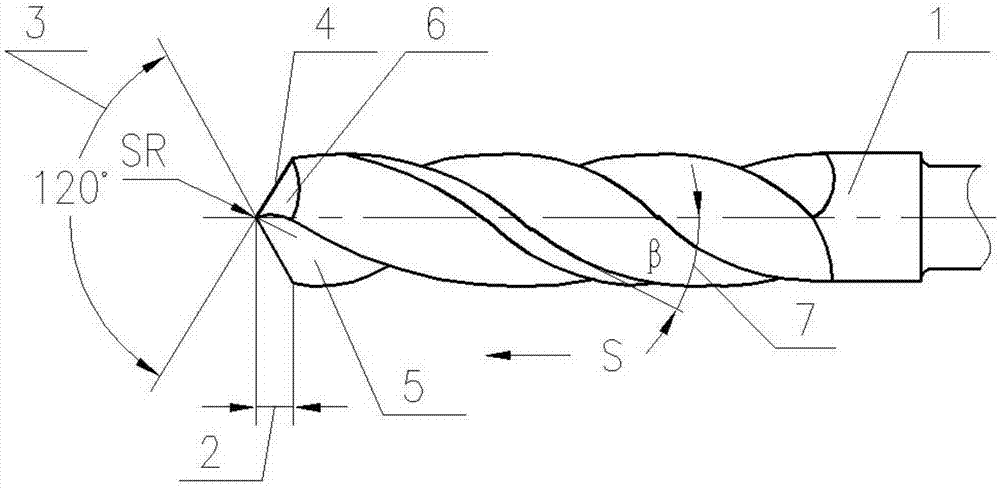

[0019] The twist drill oil groove milling cutter 1 is optimized on the basis of ordinary twist drills, and only the cutting part 2 participates in cutting. The cutting part 2 of the twist drill oil groove milling cutter 1 is composed of apex angle 2φ3, main Cutting edge 4, rake face 5, flank face 6, right helix angle β7, etc. (see image 3 ), and the apex angle 2φ3 is 118°, at this time, the main cutting edge 4 is a straight line. Such as image 3 and 4 And shown in 5, the present invention is that the twist drill oil groove milling cutter 1 apex angle 2φ3 sharpening of diameter greater than oil groove width B is sharpened to be 120 °, and the conical top sharpening is spherical arc R; The two main cutting edges 4 are From the intersection curve of two right-handed chip-holding and chip-removing spiral grooves and the cutting conical generatrix whose included angle between the generatrix and the axis is 60°, the two main cutting edges 4 are a positive and a reverse space spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com