Tiny deep hole drilling cutter with variable core thickness and variable groove width and sharpening method of cutter

A drilling tool and deep hole drilling technology, which is applied in drilling tool accessories, drilling/drilling equipment, drilling repair, etc., can solve problems such as rigidity, low strength, tool fracture failure, and tool fracture damage, so as to improve rigidity and strength, reduce excessive torque, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and examples

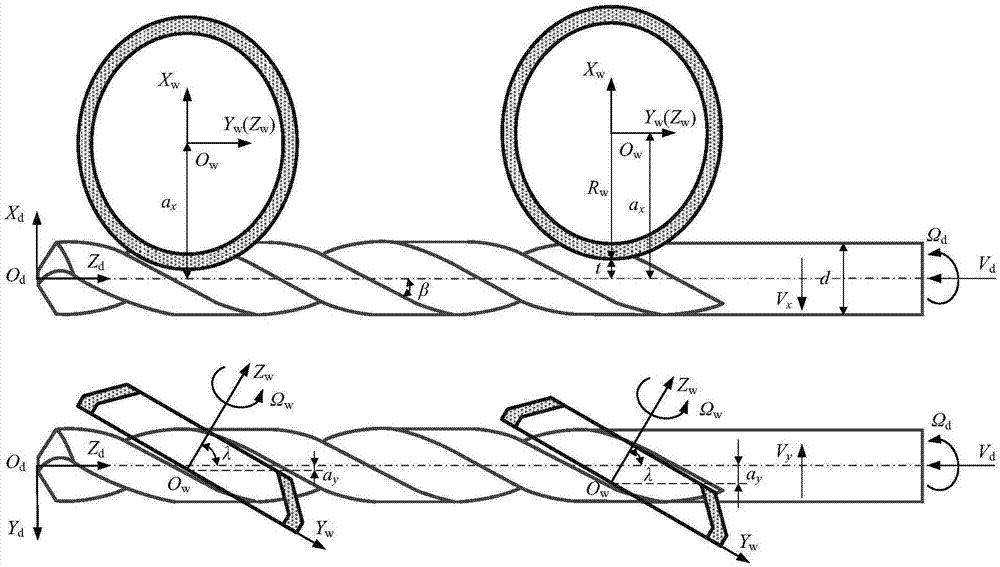

[0015] The invention provides a micro deep hole drilling tool with variable core thickness and variable groove width and a sharpening method thereof. For the grinding process of the helical groove with variable core thickness and variable groove width, see the figure 1 , there are four movements of the drilling tool during the sharpening process, around Z d Rotational movement of the shaft Ω d , along Z d Axis linear motion V d , along X d Axis linear motion V x , along Y d Axis linear motion V y . The grinding wheel has a motion about the axis Z of the grinding wheel w Rotational movement of the shaft Ω w .

[0016] where the drilling tool rotates around Z d Axis rotational movement and along the Z d The linear motion of the axis constitutes the helical motion of the drilling tool, and the grinding wheel revolves around its axis Z w The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com