Diamond grinding wheel and method for manufacturing tool bit thereof

A technology of diamond grinding wheel and manufacturing method, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., to achieve the effects of improving self-sharpening ability, expanding chip space, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Manufacturing method of diamond grinding wheel

[0021] (1) Preparation of mixture: the following components are made into powder by volume percentage: volume percentage is 25% phenolic resin, 25% diamond, 15% Fe 2 o 3 , 15% CeO 2 , 10% AL 2 o 3 , 10% Cu powder. The particle size of the diamond is 8000# (the diameter is between 0.1-0.3 microns). The particle size of the Cu powder is 400# (the diameter is between 40-50 microns).

[0022] Then, a pore-forming agent with 20% of the mass of the powder is added to the powder. The mass percent of the pore-forming agent consists of: 70% NaHCO 3 , and the rest are (NH 4 ) 2 CO 3 .

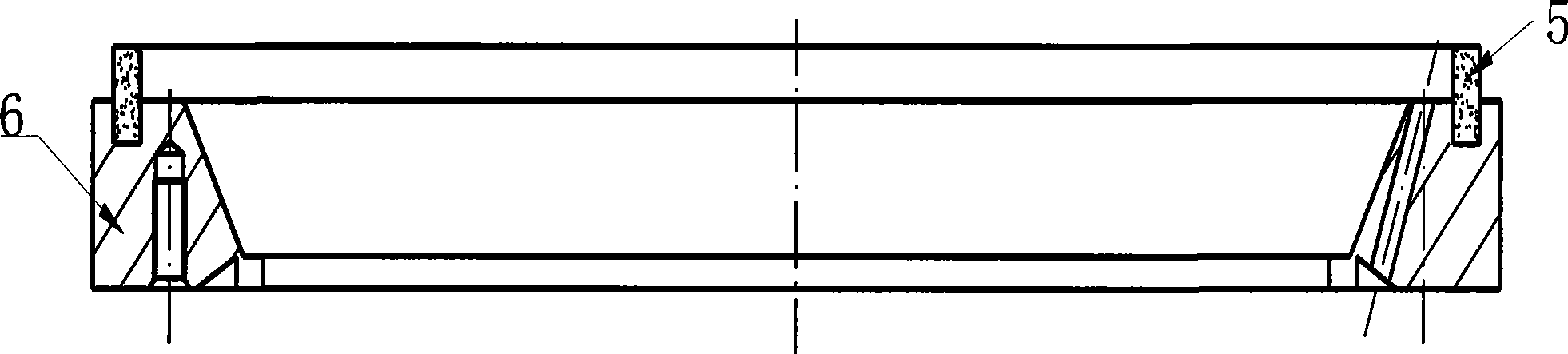

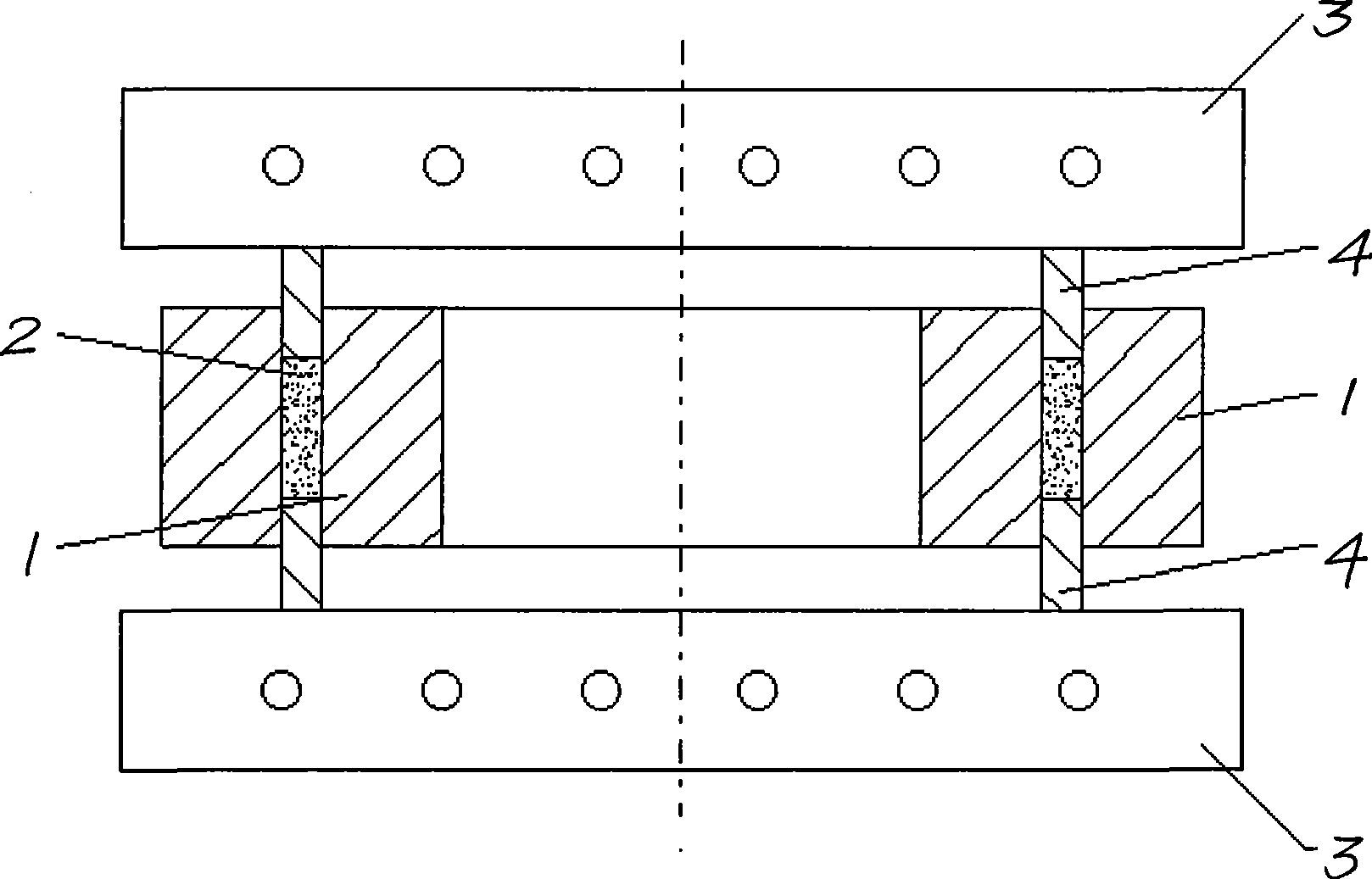

[0023] (2) see figure 2 , put the mixture into the cavity reserved in mold 1.

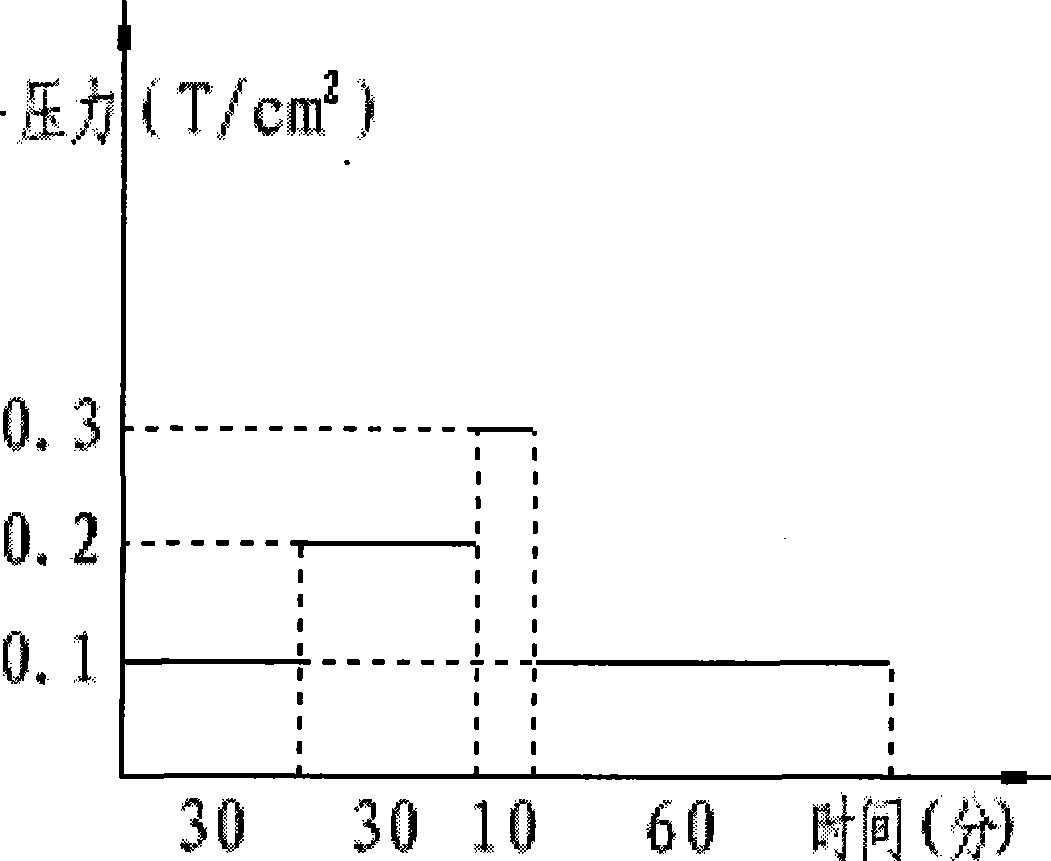

[0024] (3) The compound is heated and pressurized by the pressure ring 4 fixed on the heating plate 3, so that the compound 2 (see figure 2 ) is pressed to the required size; when the mixture is heated and pressurized, the pressure changes from 0.1t / CM wi...

Embodiment 2-5

[0028] The amount of the pore-forming agent added in Example 1 was changed to 30%, 40%, and 50% of the powder mass respectively, and the others were the same as in Example 1 to obtain Examples 2-5.

Embodiment 6-10

[0030] Change the volume percentage of the following components in the powder in Example 1 to: 30% phenolic resin, 20% diamond, and the others are the same as in Example 1 to obtain Example 6.

[0031] In the powder in embodiment 1, following component volume percent is changed to: 40% phenolic resin, 15% diamond, 10% Fe 2 o 3 . Others are the same as Example 1 to obtain Example 7.

[0032] In the powder material in embodiment 1, following component volume percentage is changed to: 35% phenolic resin, 25% diamond, 10% Fe 2 o 3 , 10% CeO 2 . Others are the same as Example 1 to obtain Example 8.

[0033] In the powder in embodiment 1, following component volume percentage is changed to: 40% phenolic resin, 25% diamond, 10% Fe 2 o 3 , 15% CeO 2 , 5% AL 2 o 3 , 5% Cu powder. Others are the same as Example 1 to obtain Example 9.

[0034] In the powder material in embodiment 1, following component volume percentage is changed to: 30% phenolic resin, 25% diamond, 15% Fe 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com