Straight fluted drill

A technology of straight groove drilling and groove bottom, which is applied in the direction of drill repairing, drilling tool accessories, drilling/drilling equipment, etc. It can solve the problems of large contact area, increased processing cost, easy breakage of drill bit, etc., and achieves a large chip space , Improve processing efficiency, good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

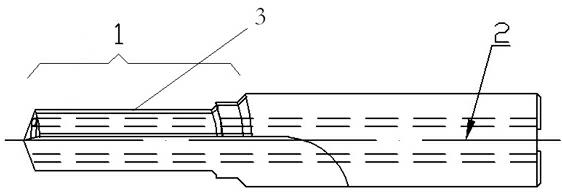

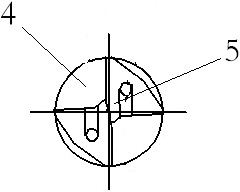

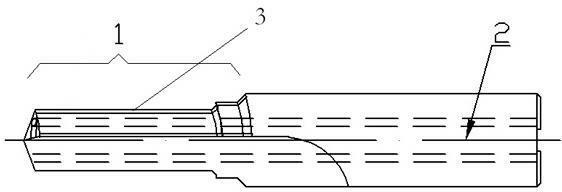

[0012] Such as figure 1 As shown, the straight flute drill shank 2 and the cutting edge 1 of this embodiment, the cutting edge 1 is provided with a side edge 3 and a chip flute 4 along its own axial direction, and the bottom of the chip flute 4 is provided with a platform 5 . This special groove design has more space for chips under the premise of ensuring a large core thickness. At the same time, the double edges formed by the platform have good guidance, which can better ensure the quality of the processed products.

[0013] The groove angle of the chip flute 4 is 105°, and the taper of the core thickness positive taper of the straight flute drill is 1:16, so as to ensure that the straight flute drill has a larger core thickness and more chip space.

[0014] The special structural design greatly improves the processing efficiency, and the tool has a longer life. The production cost is further saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com