Gradient alloying granulation method of diamond abrasive grain surface binding agent

A gradient alloy and binder technology, applied in chemical instruments and methods, abrasives, manufacturing tools, etc., can solve the problems of inability to granulate pellets, reduce product quality, different specific gravity, etc., achieve good performance, improve efficiency, high The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

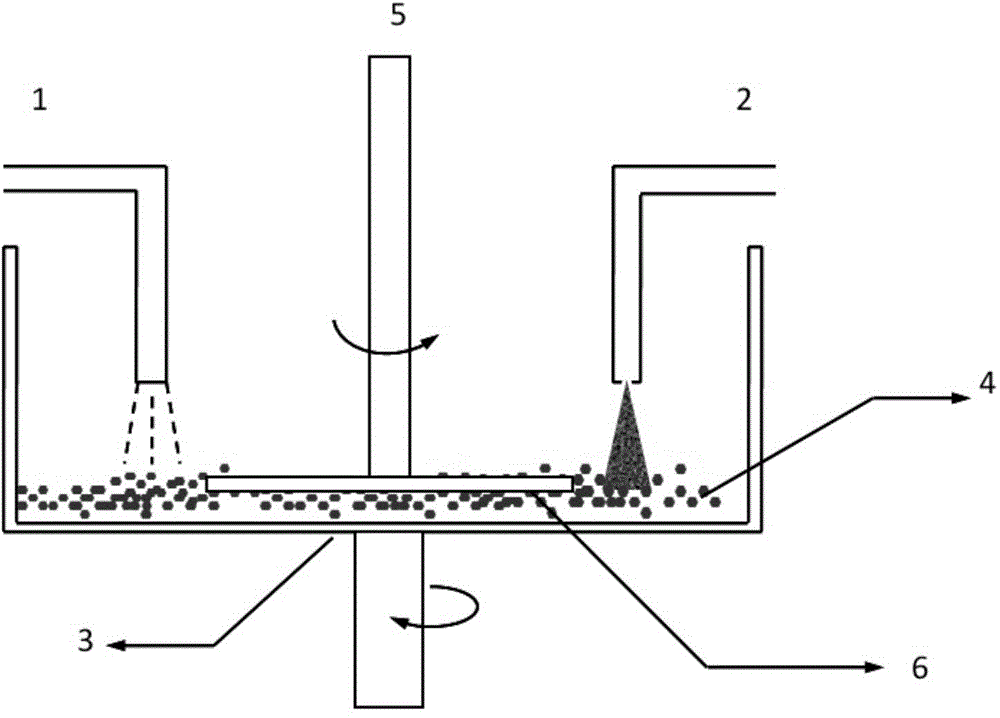

[0069] The gradient alloying granulation method of diamond abrasive surface binder, the steps are:

[0070] 1) Take 80 / 100 diamond, wash and dry it, put it into the drum of the first device of the present invention, turn on the ultrasonic agitator and drum, and start spraying after 30 seconds, and the spraying adhesive is 30% liquid phenolic resin. Close the spray nozzle, open the powder supply nozzle, and supply the powder as a cobalt-based alloy containing 5wt% Ti (that is, the mass percentage of Ti in the cobalt-based alloy containing Ti is 5%). After the powder supply is complete, turn off the powder supply nozzle, stop the ultrasonic agitator and the drum after 1 minute, take out the granulated particles, and sieve to remove the excess powder.

[0071] 2) Transfer the sieved particles into the drum of the second set of equipment, repeat the previous step, the difference is that the spray slurry is liquid paraffin, and the powder supply is 85-15 bronze powder containing 2w...

Embodiment 2

[0076] The gradient alloying granulation method of diamond abrasive surface binder, the steps are:

[0077] 1) Take 80 / 100 mesh diamond, wash and dry it, put it into the drum of the first device of the present invention, turn on the ultrasonic mixer and drum, and start spraying after 30s, the spraying adhesive is 30% liquid phenolic resin , close the spray nozzle, open the powder supply nozzle, the supply powder is cobalt-based alloy containing 5wt%Ti. After the powder supply is complete, turn off the powder supply nozzle, stop the ultrasonic agitator and the drum after 1 minute, take out the granulated particles, and sieve to remove the excess powder.

[0078] 2) Transfer the sieved particles into the drum of the second set of equipment, and repeat the previous step, the difference is that the spraying is liquid paraffin, the powder supply is a cobalt-based alloy with a Ti content of 2wt%, and the powder is removed by sieving.

[0079] 3) Transfer the sieved particles into t...

Embodiment 3

[0083] The gradient alloying granulation method of diamond abrasive surface binder, the steps are:

[0084] 1) Take 35 / 40 (or 40 / 50) mesh diamonds, wash and dry them, put them into the drum of the first device of the present invention, turn on the ultrasonic mixer and drum, and start spraying after 30s, and spray the adhesive It is 30% liquid phenolic resin. Close the spray nozzle, open the powder supply nozzle, and supply the powder as a cobalt-based alloy containing 5wt%Ti. After the powder supply is complete, turn off the powder supply nozzle, stop the ultrasonic agitator and the drum after 1 minute, take out the granulated particles, and sieve to remove the excess powder.

[0085] 2) Transfer the sieved particles into the drum of the second set of equipment, and repeat the previous step, the difference is that the spraying is liquid paraffin, and the powder supply is cobalt-based alloy powder containing 2wt% Ti, and the powder is removed by sieving.

[0086] 3) Transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com