Superhard grinding tool and preparation method thereof

A super-hard material abrasive tool and abrasive tool technology, applied in the field of abrasive tools and abrasives, can solve problems such as abrasive tool failure, peeling, and abrasives are easy to fall off and coat into flakes, so as to prolong the service life, uniform temperature field, and shorten the preparation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

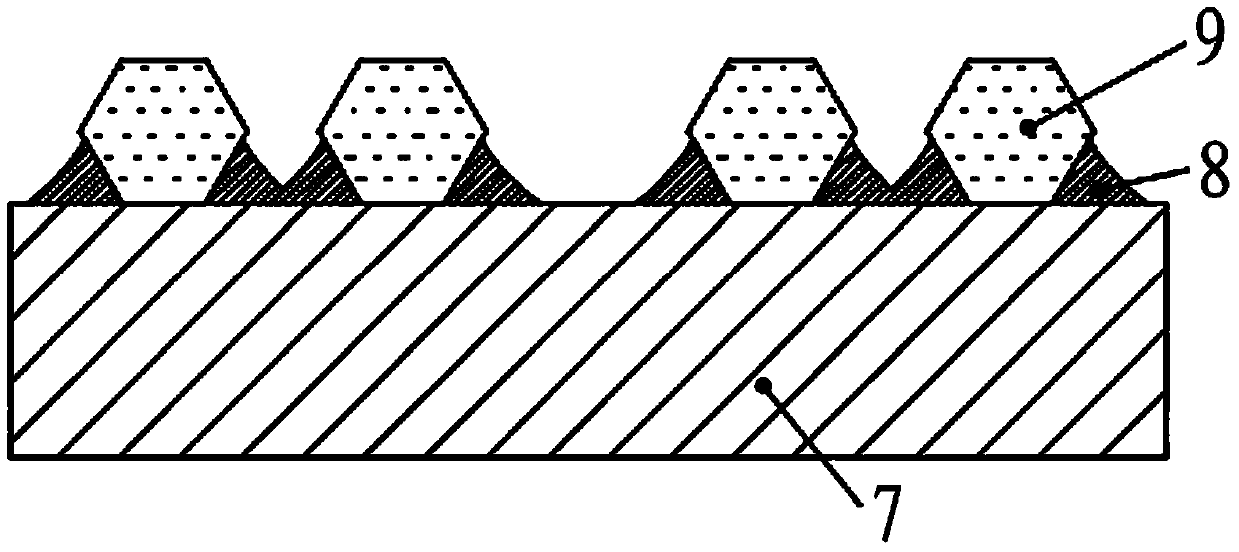

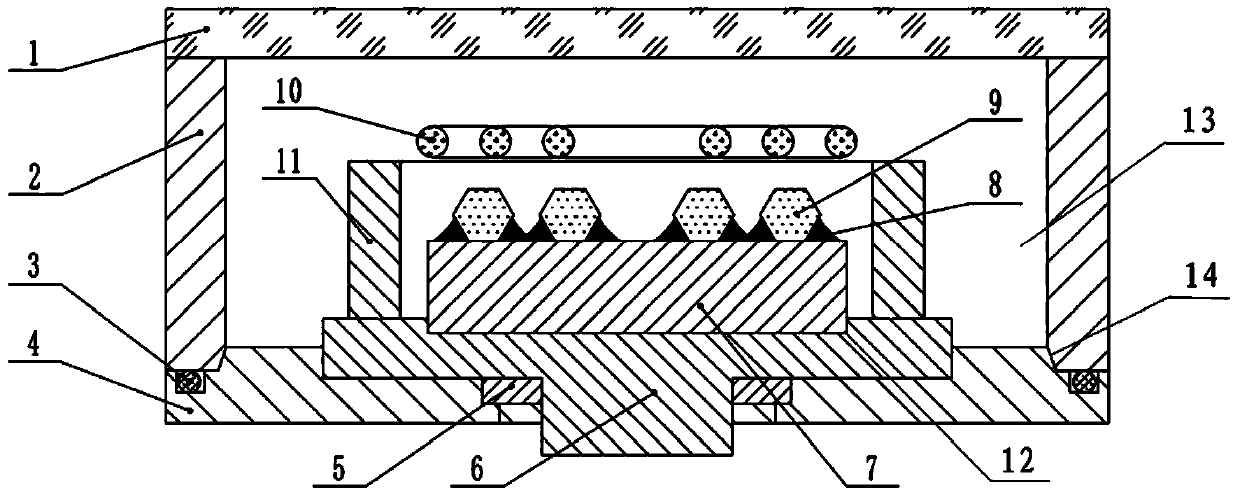

[0038] The superhard material grinding tool of the present embodiment, as figure 1 As shown, it includes abrasive tool substrate 7 and abrasive material 9, and said abrasive material 9 is consolidated on abrasive tool substrate 7 through coating 8; said coating layer 8 comprises the following components in mass percentage: Cr 20%, P 15%, balance For you. The thickness of the coating layer 8 is less than half of the grain size of the abrasive material 9 . The mesh of the abrasive is 30 / 35.

[0039] The base of the grinding tool is a metal steel base; the abrasive is diamond.

[0040] The preparation method of the superhard material grinding tool of the present embodiment comprises the following steps:

[0041] 1) Pretreatment before plating: clean the abrasive tool substrate and abrasive, and set aside;

[0042] 2) prepare electroplating solution; get phosphorous acid solution, add nickel salt, chromium salt as complexing agent, obtain electroplating solution;

[0043] Des...

Embodiment 2

[0049] The superhard material grinding tool of the present embodiment comprises a grinding tool substrate and an abrasive, and the abrasive is consolidated on the grinding tool substrate through a coating; the coating comprises the following components in mass percentage: Cr 15%, P 15%, and the remaining The amount is Ni. The thickness of the coating layer is less than half of the abrasive particle diameter. The mesh of the abrasive is 80 / 100.

[0050] The abrasive base is a hard alloy base; the abrasive is cubic boron nitride.

[0051] The preparation method of the superhard material grinding tool of the present embodiment comprises the following steps:

[0052] 1) Pretreatment before plating: clean the abrasive tool substrate and abrasive, and set aside;

[0053] 2) prepare electroplating solution; get phosphorous acid solution, add nickel salt, chromium salt as complexing agent, obtain electroplating solution;

[0054] Described electroplating solution comprises the com...

Embodiment 3

[0059] The superhard material grinding tool of the present embodiment comprises a grinding tool substrate and an abrasive, and the abrasive is consolidated on the grinding tool substrate through a coating; the coating comprises the following components in mass percentage: Cr 20%, P 5%, and the remaining The amount is Ni. The thickness of the coating layer is less than half of the abrasive particle diameter. The mesh of the abrasive is 270 / 325.

[0060] The grinding tool substrate is a cemented carbide substrate; the abrasive is diamond.

[0061] The preparation method of the superhard material grinding tool of the present embodiment comprises the following steps:

[0062] 1) Pretreatment before plating: clean the abrasive tool substrate and abrasive, and set aside;

[0063] 2) prepare electroplating solution; get phosphorous acid solution, add nickel salt, chromium salt as complexing agent, obtain electroplating solution;

[0064] Described electroplating solution comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com