Strip workpiece production line and strip workpiece production process

A strip-shaped, production line technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of complex cross-section shape machining accuracy requirements, poor machining accuracy, high labor intensity, etc., to solve the problem of low space utilization, operation Convenience and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

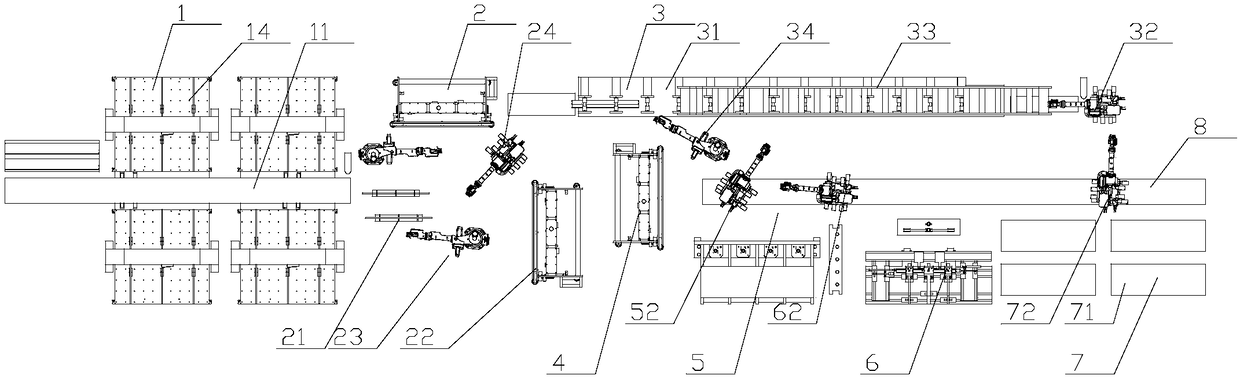

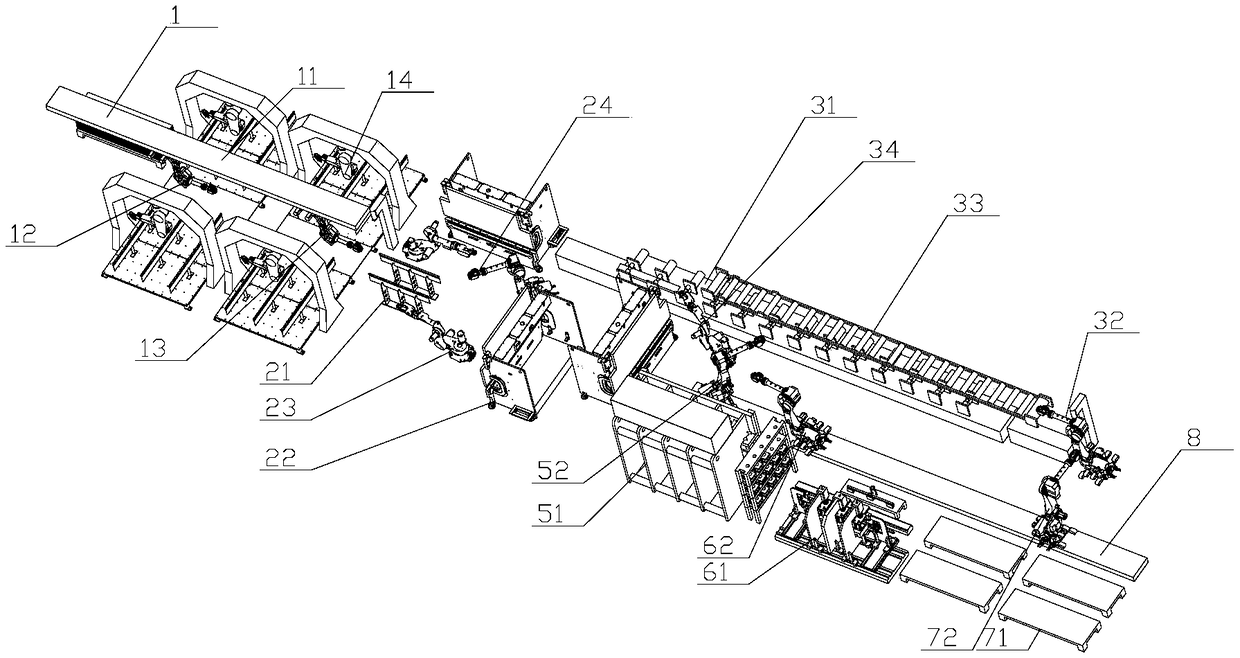

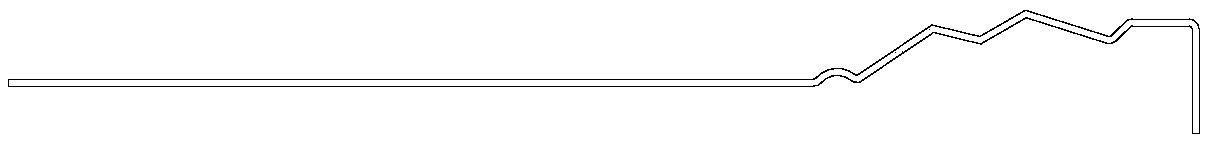

[0036] The present invention as Figure 1-8 As shown, several through holes are provided on the strip-shaped workpiece, and there are several corners and a step in the strip-shaped workpiece;

[0037] The production line includes a laser trimming component 1, a primary bending component 2, a cold bending component 3, a secondary bending component 4, a forming component 5, a punching component 6 and a discharging component 7;

[0038] The laser edge trimming assembly 1 includes a top beam 11, a retrieving manipulator 12, a material unloading manipulator 13 and at least one three-dimensional laser cutting machine 14, the top beam 11 is fixedly connected above the three-dimensional laser cutting machine 14, and the taking The top of the material manipulator 12 is slidably connected in the top beam 11, and is used to place the workpiece in the three-dimensional laser cutting machine 14, and the top of the blanking manipulator 1 is slidably connected in the top beam, and is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com