Board back insertion type circuit breaker characteristic detection and test device

A test device and circuit breaker technology, applied in circuit breaker testing and other directions, can solve problems such as reducing work efficiency, increasing heat loss, and increasing investment costs, eliminating energy consumption and differences, improving accuracy and efficiency, and improving space. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

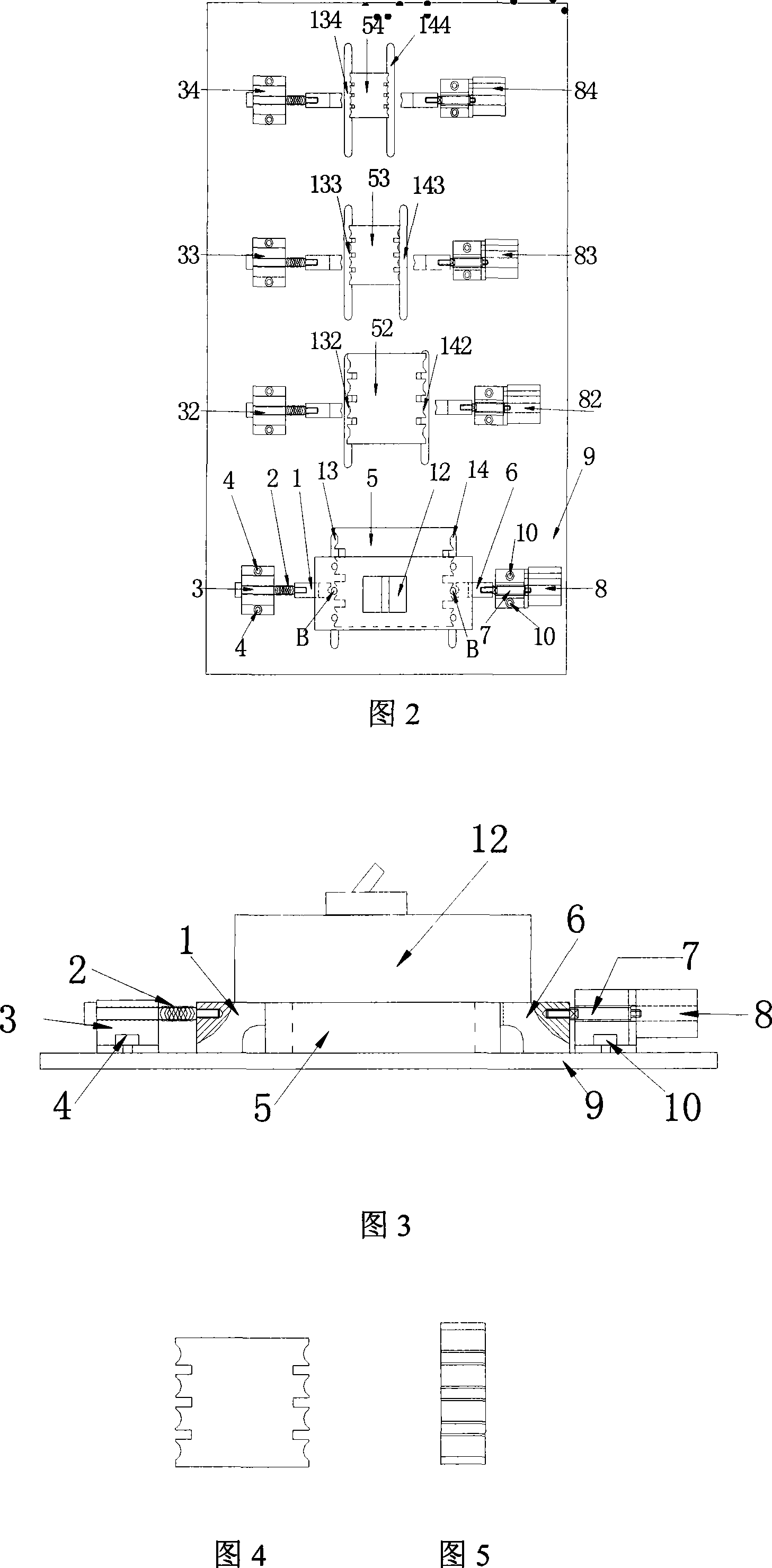

[0014] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

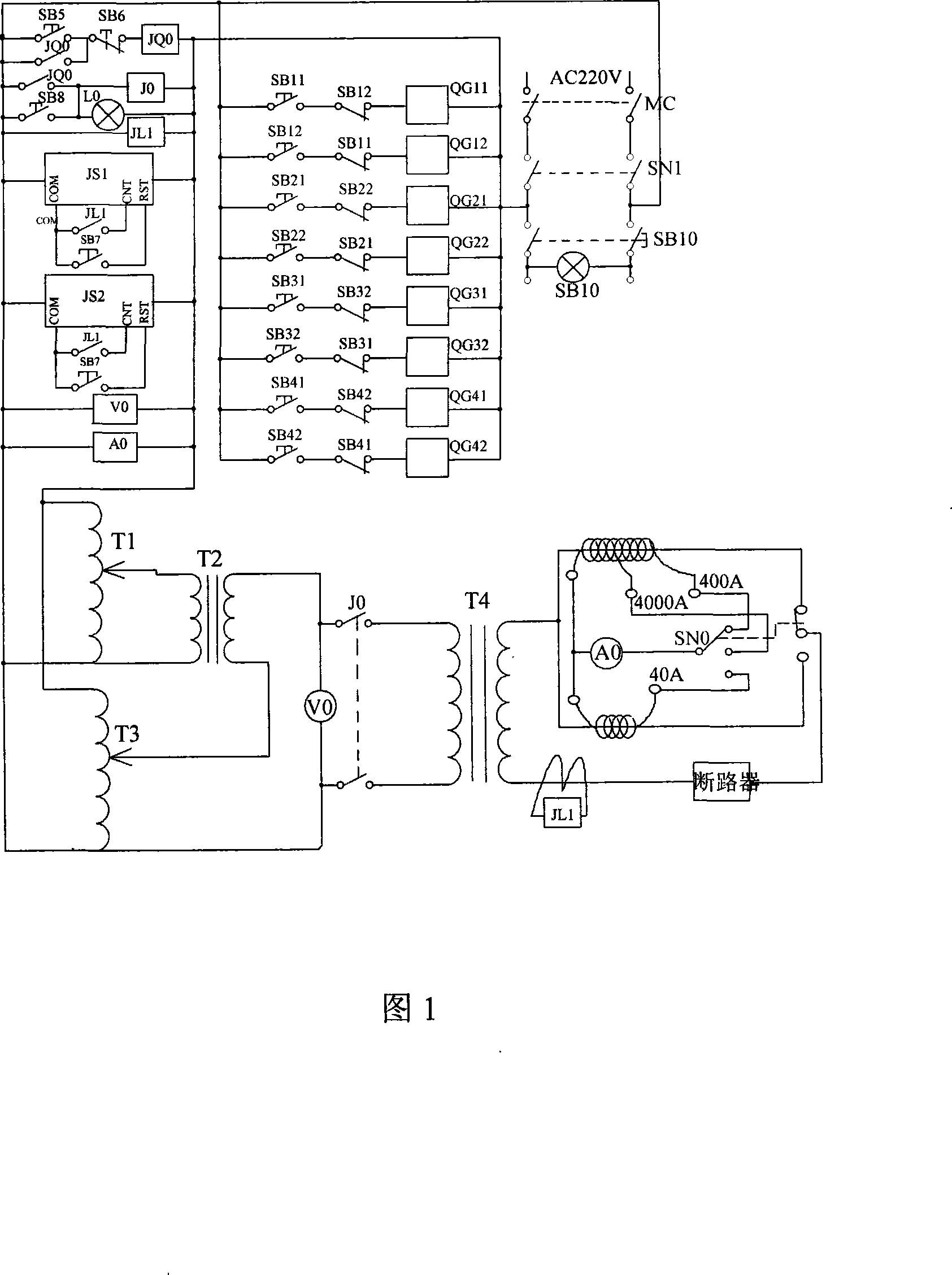

[0015] As shown in Figure 1, the mains 220V passes through the miniature circuit breaker MC and then connects to the button SB10 through the rotary switch SN1 and then to its indicator light to provide an independent 220V AC power supply. The other one is connected to the main control circuit. The control circuit includes a pneumatic electrode clamping control circuit and an overload characteristic test circuit. In the pneumatic electrode clamping control circuit, the normally open contact of button SB11 is connected in series with the normally closed contact of button SB12. , connected to the pneumatic electrode of the cylinder QG1 to clamp the solenoid valve coil QG11, and after the normally open contact of the button SB12 is connected in series with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com