Efficient calcium thioaluminate type bulking agent and its preparing process

A technology of calcium sulfoaluminate and calcium sulfoaluminate, which is applied in the field of improved design of concrete expansion additives and supporting production technology, and can solve the problems of difficult realization, high dosage, high price and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

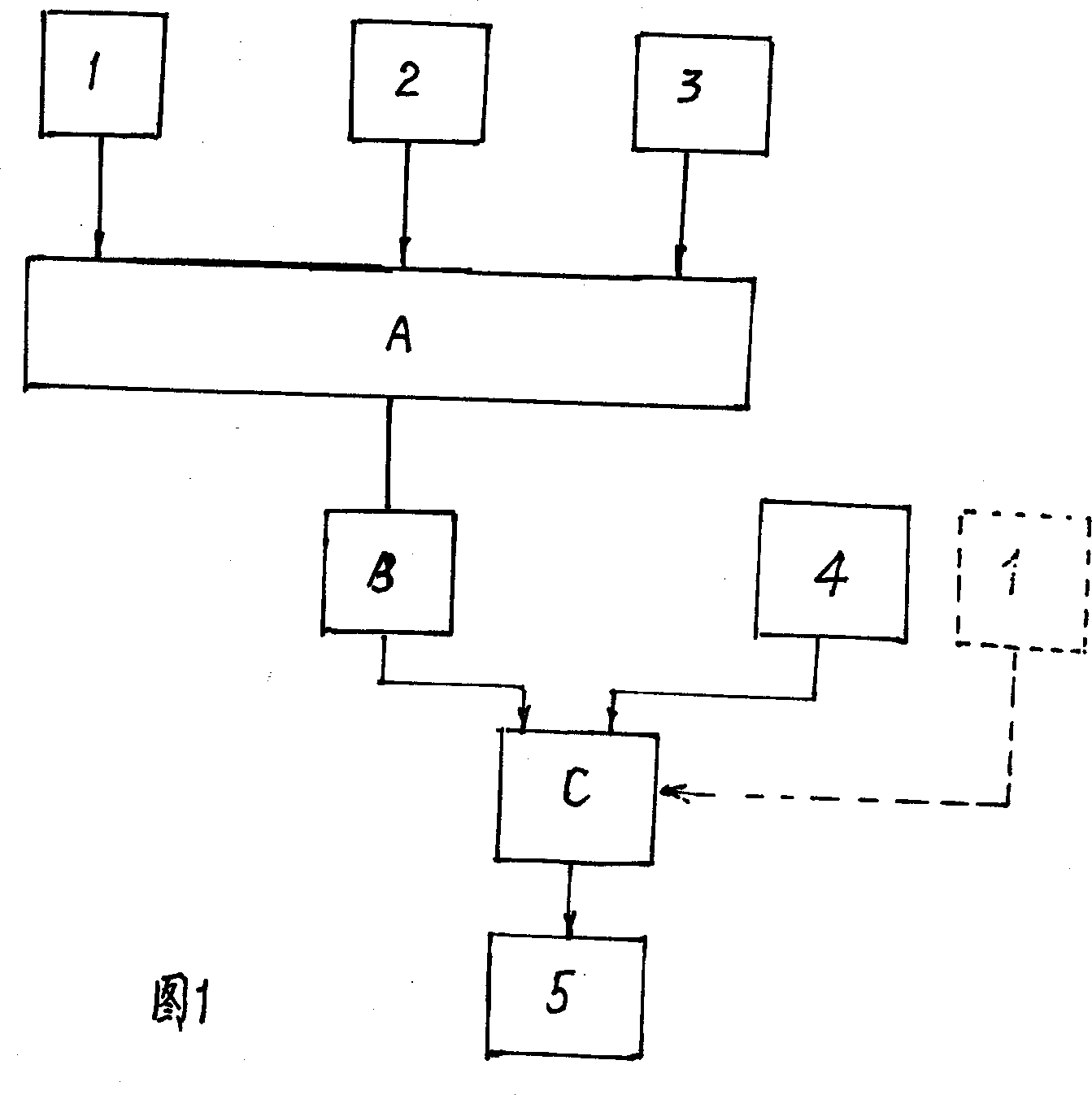

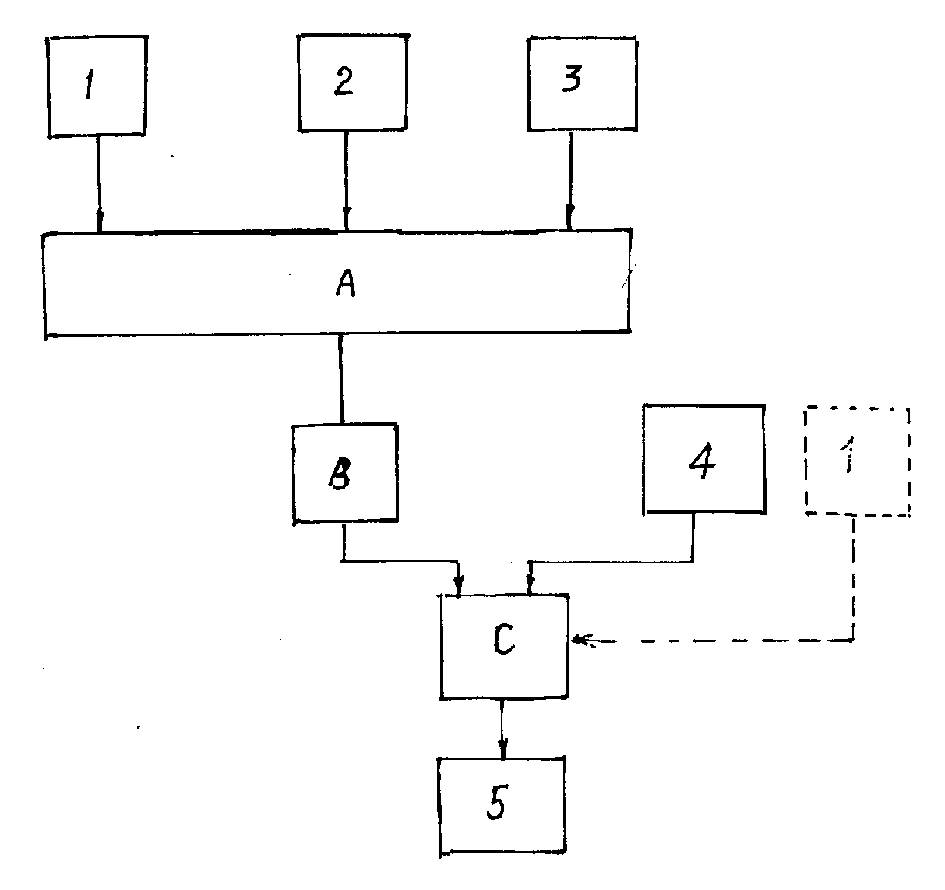

Image

Examples

Embodiment Construction

[0011] In order to achieve the purpose of the present invention, this improvement designs the production process of CAS type expansion agent into two main proportioning processes. Firstly, the raw materials of limestone, gypsum and bauxite are put into the rotary kiln for calcination. , the embodiment of its proportioning is as follows: (percentage by weight)

[0012] Examples Limestone Gypsum Bauxite

[0013] 1 85 10 5

[0014] 2 83 2 15

[0015] 3 70 15 15

[0016] 4 50 20 30

[0017] According to the above examples, the three raw materials are pulverized and prepared, homogenized and put into a rotary kiln at 1200° C. to 1400° C. to be calcined into granular clinker containing calcium sulfoaluminate.

[0018] The actual content of calcium sulfoaluminate in the clinker and the gypsum raw meal are rationally combined again, and limestone can also be added appropriately to adjust the characteristics. The specific examples are as follows:

[0019] Examples Calcium sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com