Efficient calcium thioaluminate type bulking agent and its preparing process

A technology of calcium sulfoaluminate and expansion agent, which is applied in the field of improved design of concrete expansion additives and supporting production process, can solve the problems of inability to apply, long expansion period and high alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

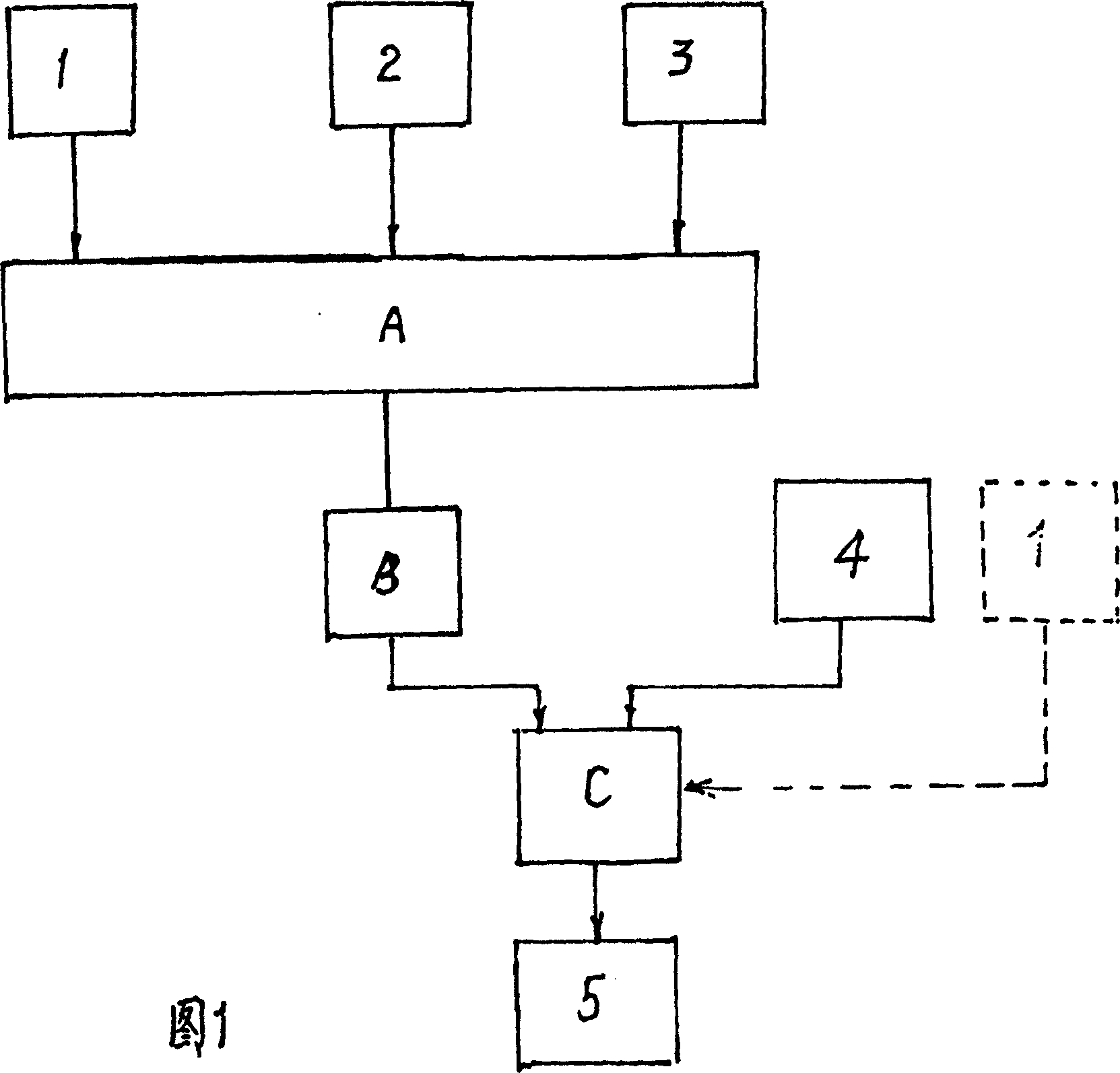

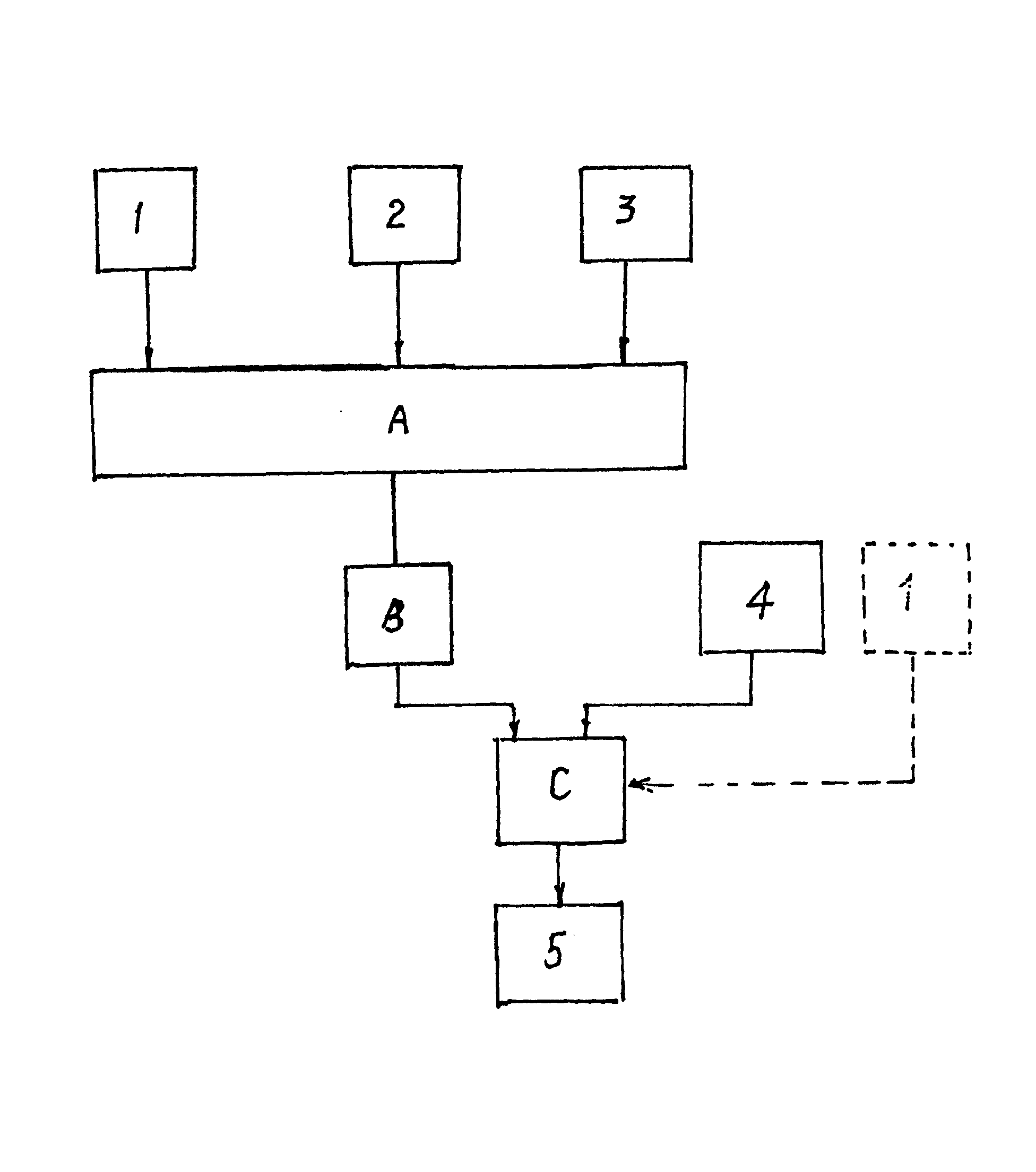

Image

Examples

Embodiment Construction

0

[0022] Mix and pulverize according to the formula ratio of the above examples and send it into an air mixer for homogenization to become a finished product.

[0023] In order to ensure the content of active ingredients and reduce the content of harmful ingredients to ensure the quality of raw materials, it is the basic condition for the selection of raw materials. On the basis of quality assurance, limestone can be selected from lime, calcium oxide or its main components. The industrial waste slag is the raw material of calcium quality. Natural bauxite, alumina or industrial waste slag and tailings with alumina as the main component can be used to replace bauxite as aluminum raw material, and natural anhydrite, hydrated gypsum or phosphorus can be used. Gypsum, fluorogypsum to replace gypsum. However, it should be ensured by testing that the CaO content in the calcium raw materials used in the preparation of calcium sulfoaluminate clinker should be greater than 53...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com