Inner tube with film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

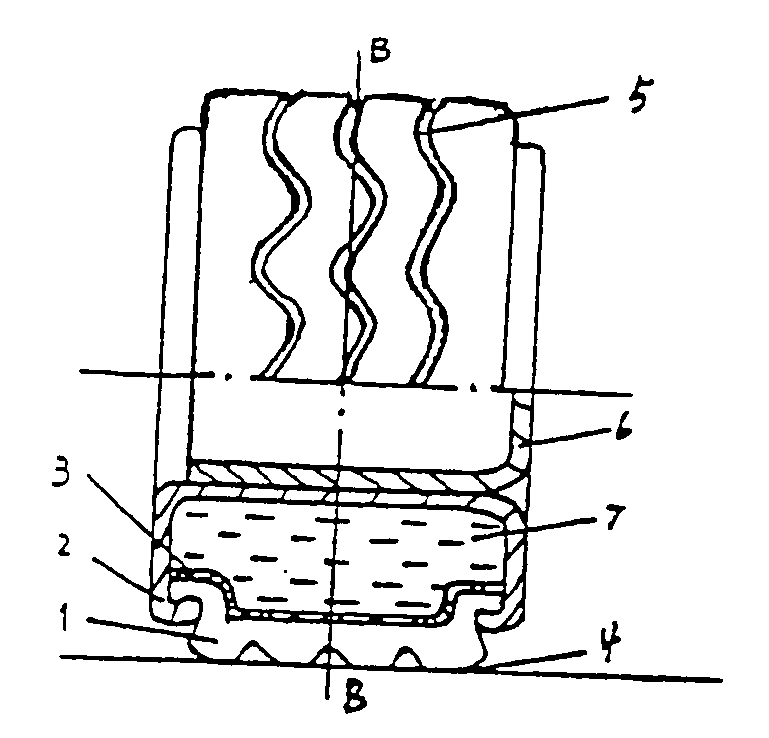

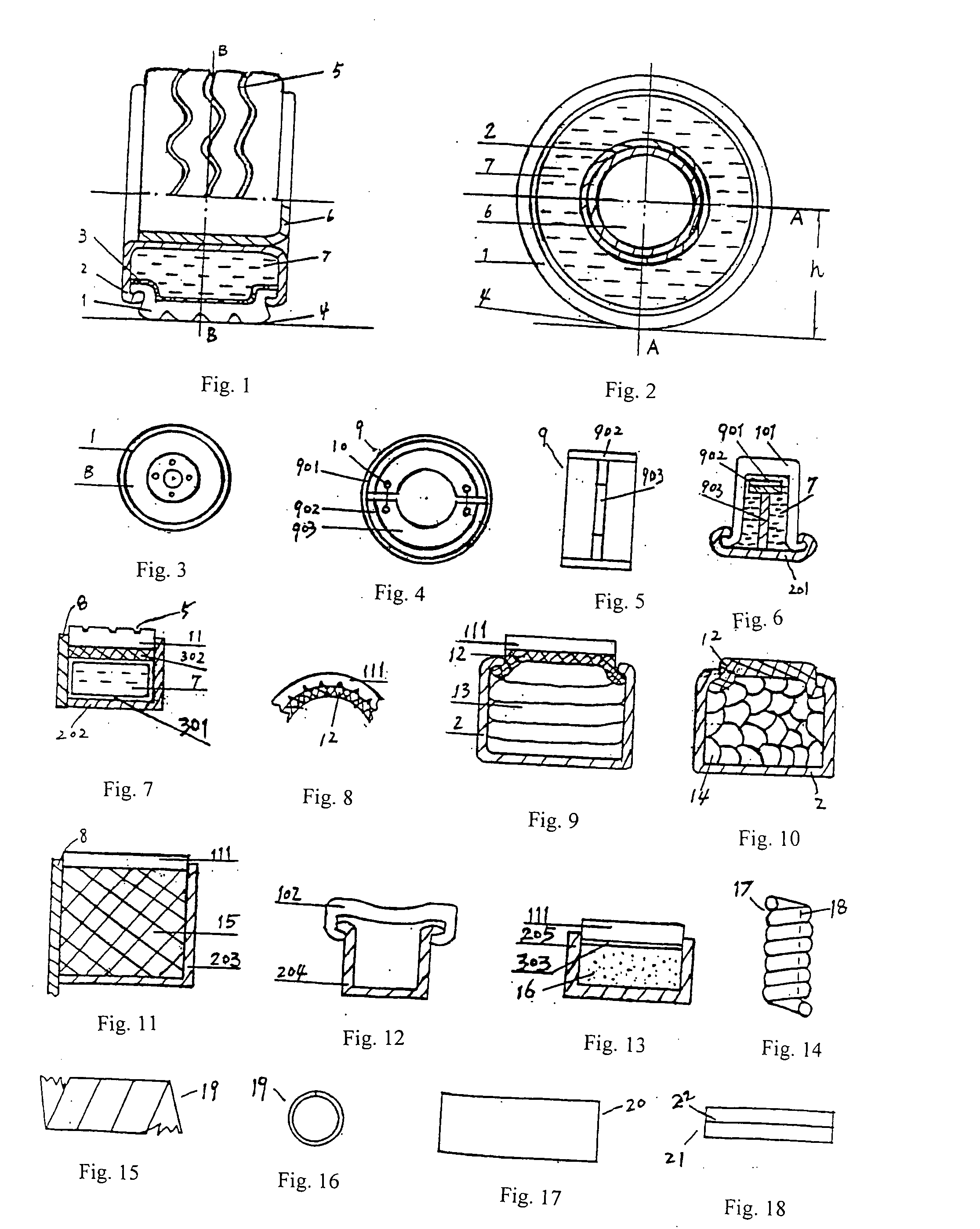

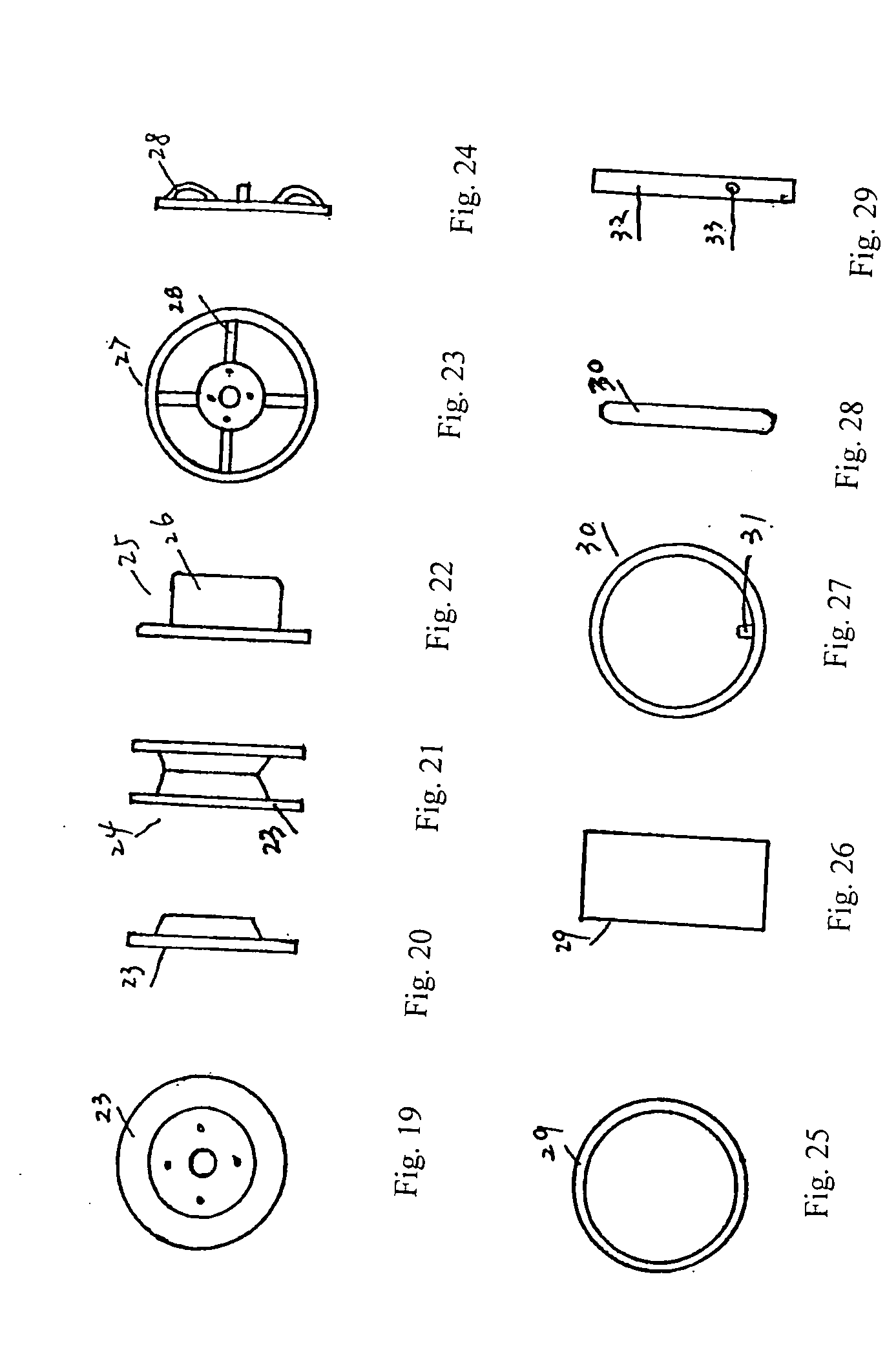

[0121] Referring to FIG. 1 and FIG. 2, the fluid-stuffed steel-tired wheel according to the preferred embodiment of the present invention is illustrated. The outer cover 1 and the steel ring 2 are detachably engaged by conventional means within the art. A plastic membrane 3 is overlappedly coated on the inner wall of the outer cover 1 so as to replace the conventional inner tube of a tire. It is noted that there is an engaging interface defined between the plastic membrane 3 and the inner wall of the outer cover 1. The landing portion 4 of the outer cover 1 is longitudinally flatted biasing the ground. Here, the landing portion refers to the circumferential surface of the outer cover 1 being contacted with the ground, so that a rotational motion of such wheel will enable turning part of the outer cover to land on the ground. The tire tread 5 is defined on the circumferential surface of outer cover 1. The steel ring 2 is coupled to the wheel rotational axial shaft through a steel bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com