Lubricating oil conveying device of internal combustion engine with four cylinders surrounding shaft

A conveying device and lubricating oil technology, applied in the direction of engine lubrication, pressure lubricant, mechanical equipment, etc., can solve the problems of increased manufacturing cost of internal combustion engines, fast wear and tear of internal combustion engines, increased volume of internal combustion engines, etc., to achieve improved service life, The effect of saving space and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

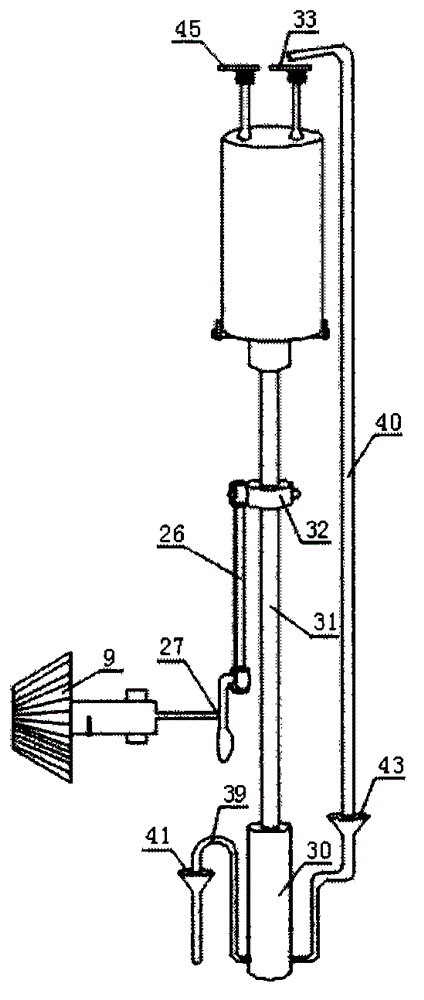

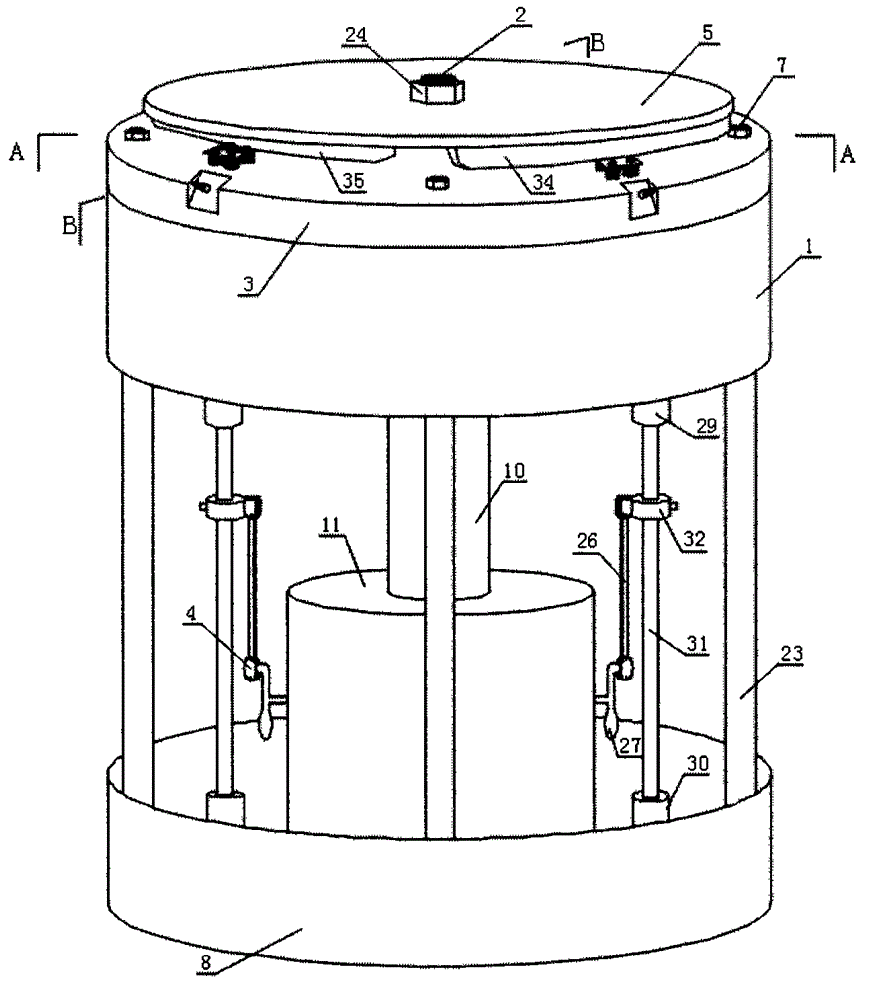

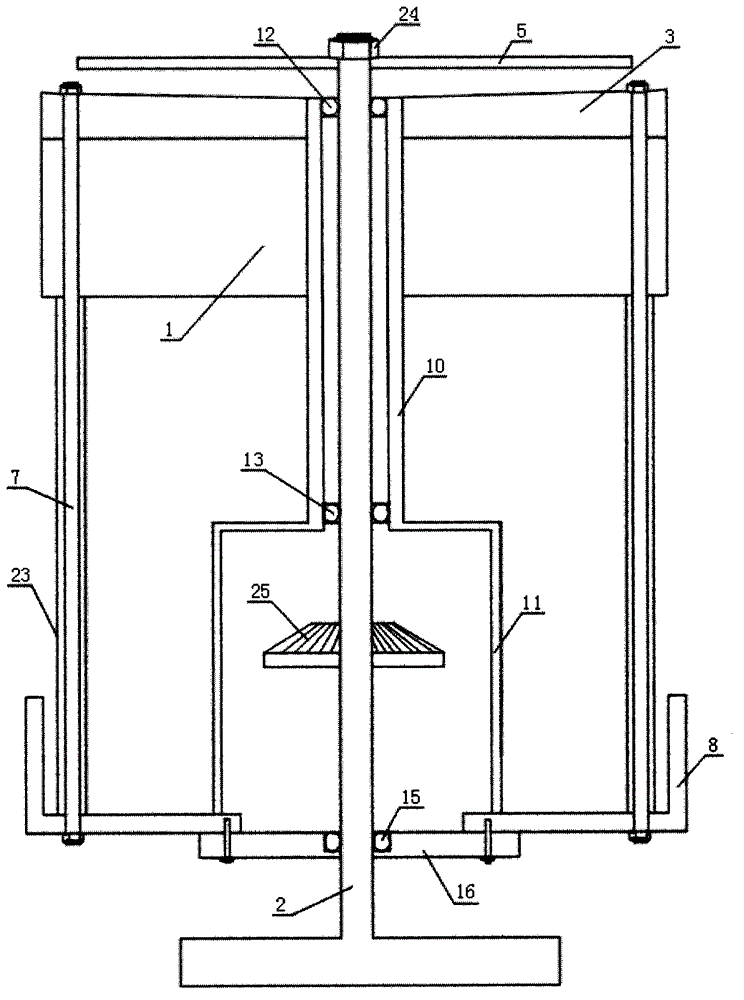

[0021] Such as figure 1 and Figure 4 As shown, the internal combustion engine of this embodiment includes a cylinder block 1, an output power shaft 2, a cylinder head 3, a crankshaft connecting rod device 4, a cam disc 5, an anti-eccentric wear device and a lubricating oil delivery device, and the cylinder block 1 is provided with cylinder holes 18 and piston 28, crankshaft connecting rod device 4 includes crankshaft 27, connecting rod 26 and crankshaft gear 9, anti-eccentric wear device includes upper bushing 29, lower bushing 30 and piston guide rod 31, lubricating device 6 is provided with lubricating oil tank 8, The lubricating oil delivery device is provided with an oil suction anti-backflow valve 37, an oil injection anti-backflow valve 38, an oil suction pipe 39 and an oil injection pipe 40. The lower end of the lower bushing 30 is fixed on the bottom plate of the lubricating oil tank 8. It communicates with the bottom of the lower bushing 30, the open end of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com