RH dry type vacuum refining apparatus

A technology of vacuum refining and vacuuming device, applied in the field of RH dry vacuum refining device, can solve the problems of reducing the failure rate of the device, affecting the refining effect, and high failure rate of the vacuum device, so as to reduce the failure rate of the device and ensure long-term operation. , Eliminate the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following examples, the RH dry vacuum refining device is a 180T refining device.

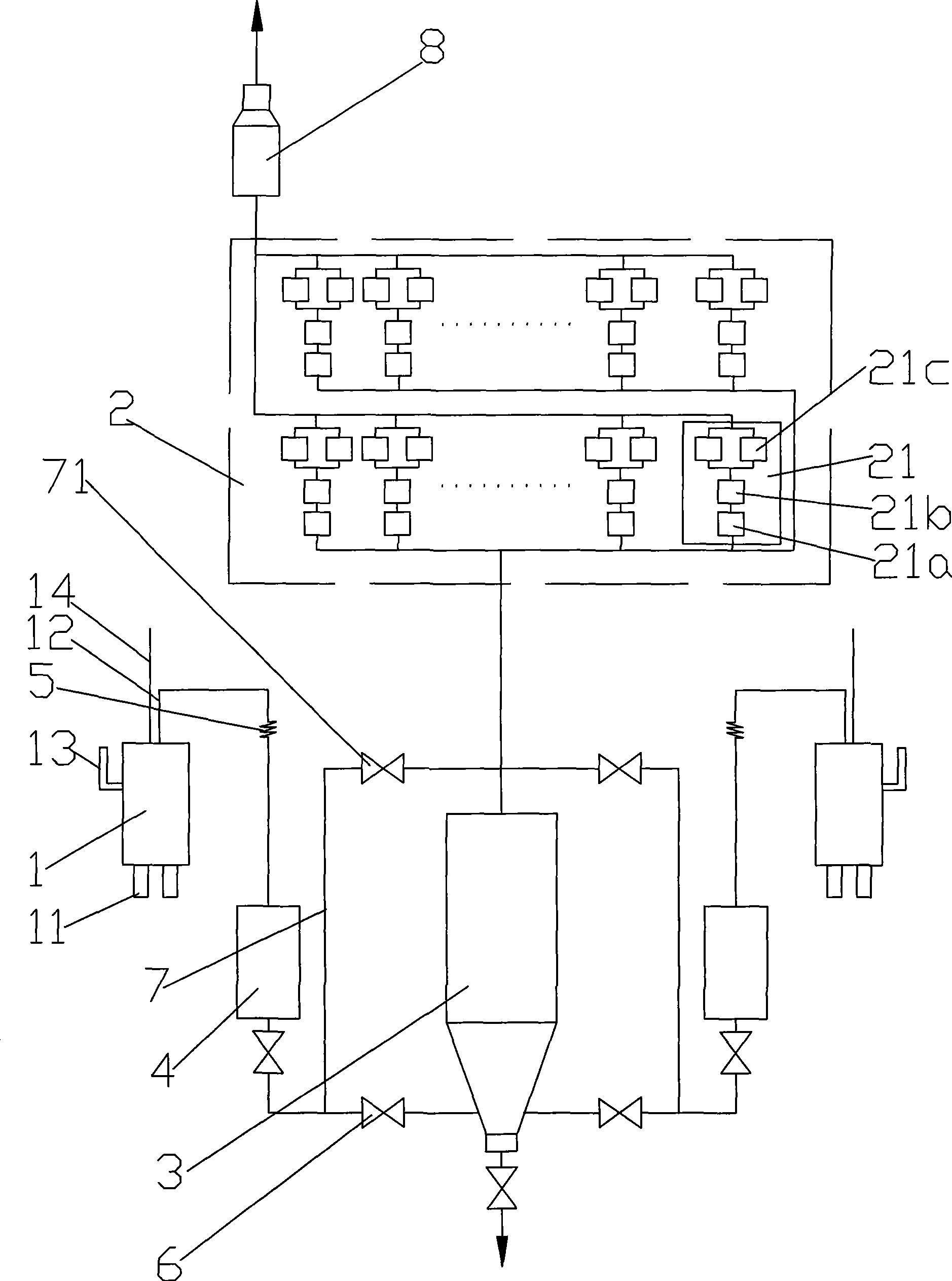

[0019] Accompanying drawing is the structure schematic diagram of the present invention, as shown in the figure: the RH dry type vacuum refining device of the present embodiment, comprises vacuum tank 1 and vacuumizing device 2, and described vacuum tank 1 is provided with dip tube 11, hot bend tube 12, Alloy pipeline 13 and oxygen top-blowing gun 14, the inlet of the vacuum pumping device 2 is connected with the hot elbow 12, the vacuum pumping device 2 is a dry vacuum pump device, and the dry vacuum pump device 2 consists of eighteen groups of three-stage Vacuum pump group 21 composed of vacuum pumps, in which the first stage is an IDX1300 double-exhaust screw pump 21a with frequency conversion control, the second stage is a SN7000 mechanical Roots pump 21b, and the third stage is two HV40000 mechanical Roots pump 21c; primary vacuum pump 21a, secondary vacuum pump 21b and tertia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com