Gas phase catalytic esterification process for synthesizing butyl acetate

A gas-phase catalytic ester, butyl acetate technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high reaction temperature, overheating, low reaction gas space velocity, etc., to achieve uniform reaction temperature, Simple process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Using our invented SO 4 2- / Fe 2 o 3 -ZrO 2 -SiO 2 The solid acid catalyst (patent publication number: CN1323655A) is compressed into tablets with a hydraulic press at 25 MPa, and crushed to a size of 20-40 mesh.

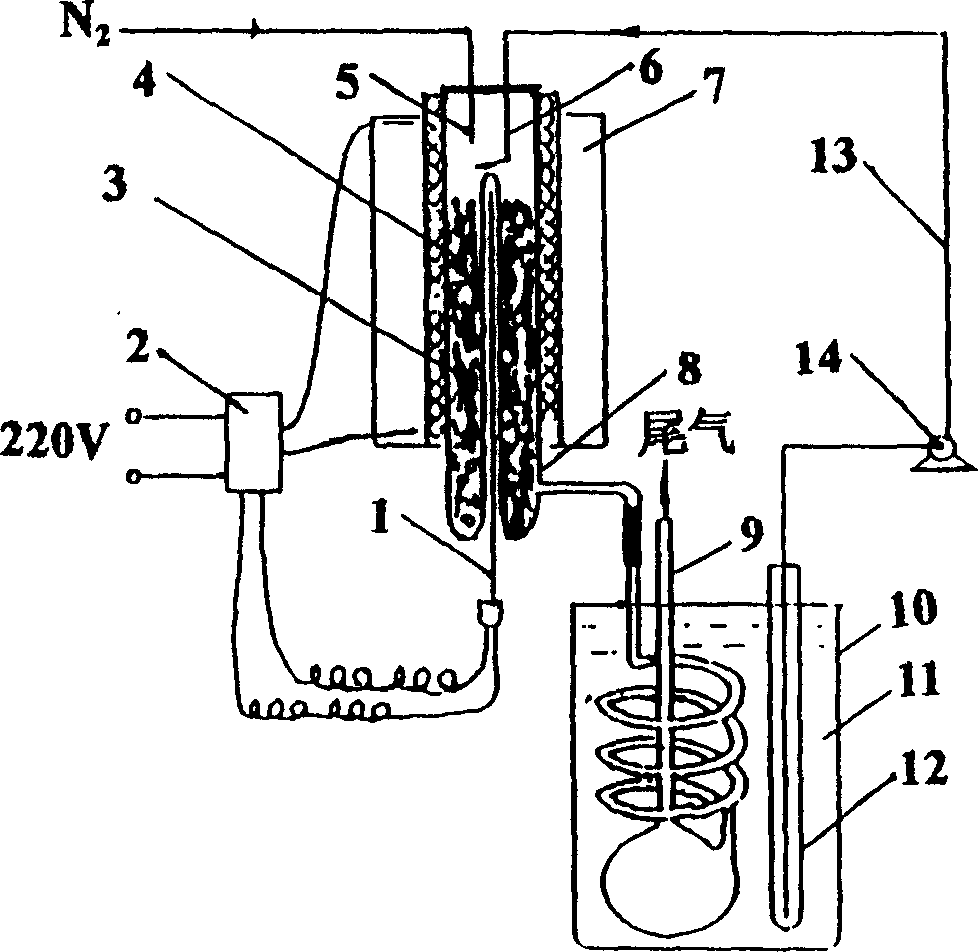

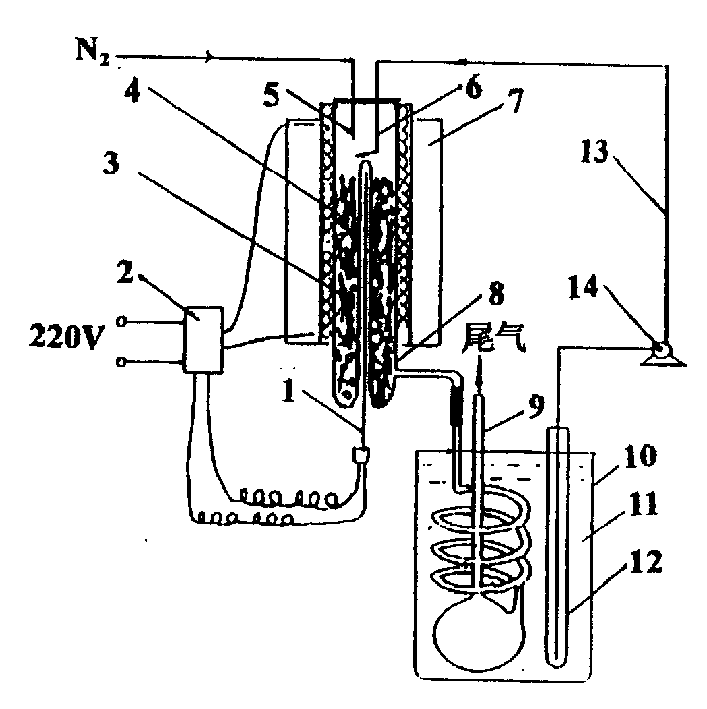

[0013] Vapor-phase acetic acid / butanol esterification in figure 1 Carry out on the shown device, at first add n-butanol and glacial acetic acid in reaction raw material bottle 12, in quartz reaction tube 8, pack solid acid catalyst; After being heated to reaction temperature, start peristaltic pump 14 and N 2 Jet gas 5, after the reaction material (acetic acid / butanol molar ratio is 1: 1) enters the reaction tube, start timing, reaction conditions: reaction temperature 423K, catalyst addition: 5g, reaction material gas space velocity (GHSV)=761h -1 , reaction time: 2h, jet gas: N 2 , flow rate: 5ml.min -1 ; After the inspection, turn off the pump and the jet gas. Sampling was carried out in the snake-type condenser 9, and the composition of the produ...

Embodiment 2

[0015] Using our invented SO 4 2- / Fe 2 o 3 -ZrO 2 -SiO 2 The solid acid catalyst (patent publication number: CN1323655A) is compressed into flakes with a hydraulic press at 25 MPa, and crushed to a size of 40-60 mesh.

[0016] Vapor-phase acetic acid / butanol esterification in figure 1 Carry out on the shown device, at first add n-butanol and glacial acetic acid in reaction raw material bottle 12, in quartz reaction tube 8, pack solid acid catalyst; After being heated to reaction temperature, start peristaltic pump 14 and N 2 Jet gas 5, after the reaction material (acetic acid / butanol molar ratio is 1: 1) enters the reaction tube, start timing, reaction conditions: reaction temperature 423K, catalyst addition: 5g, reaction material gas space velocity (GHSV)=380h -1 , reaction time: 2h, jet gas: N 2 , flow rate: 5ml.min -1 ; After the inspection, turn off the pump and the jet gas. Sampling was taken from the snake-type condenser 9, and the product composition was analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com